Flow state display comb tube for automobile wind tunnel

A flow state display, automotive wind tunnel technology, applied in the direction of vehicle testing, measurement devices, instruments, etc., can solve the problems of unable to truly reflect the vehicle or model flow state, large flow field interference, large flow field resistance, etc. Small, reduce interference, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

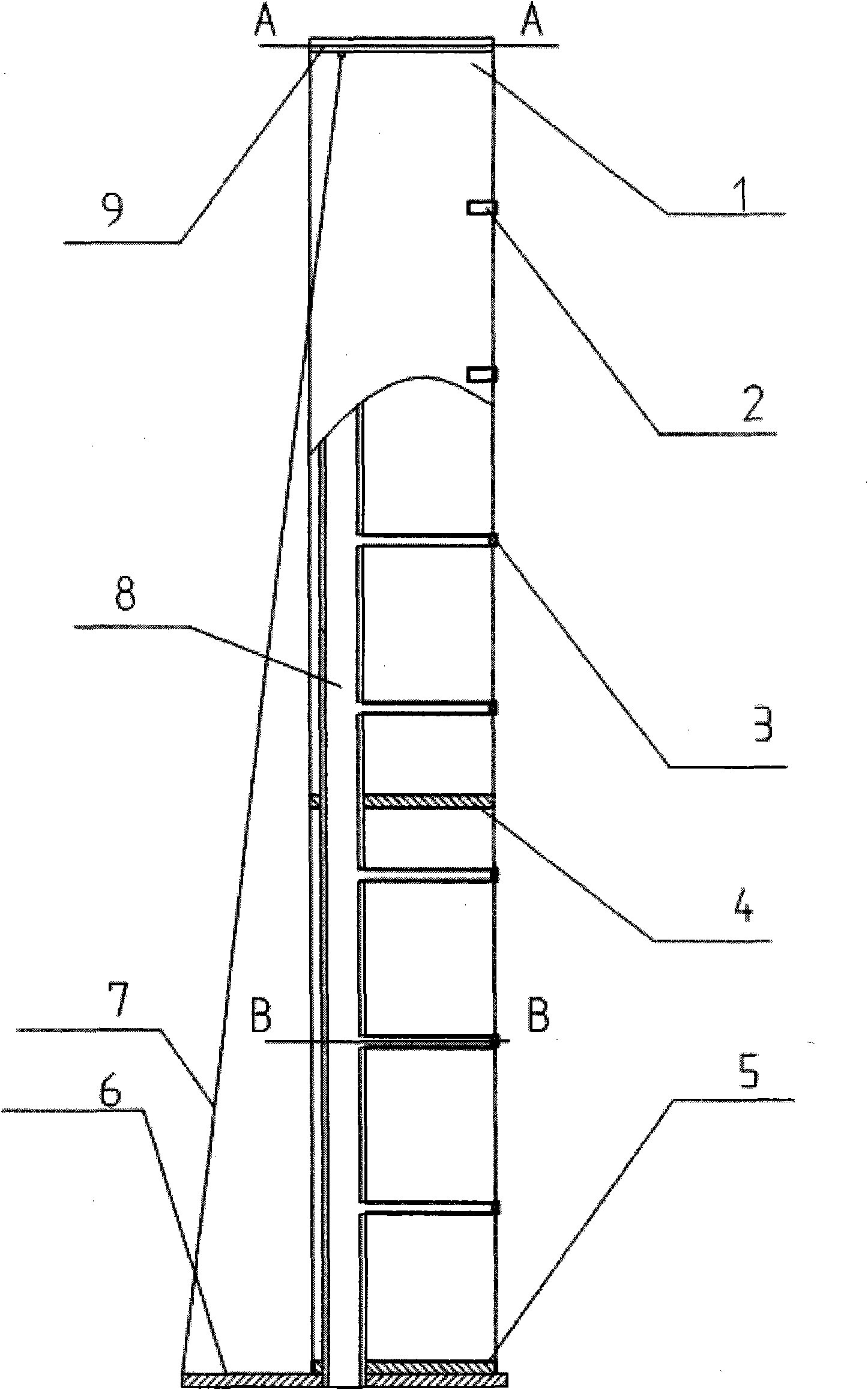

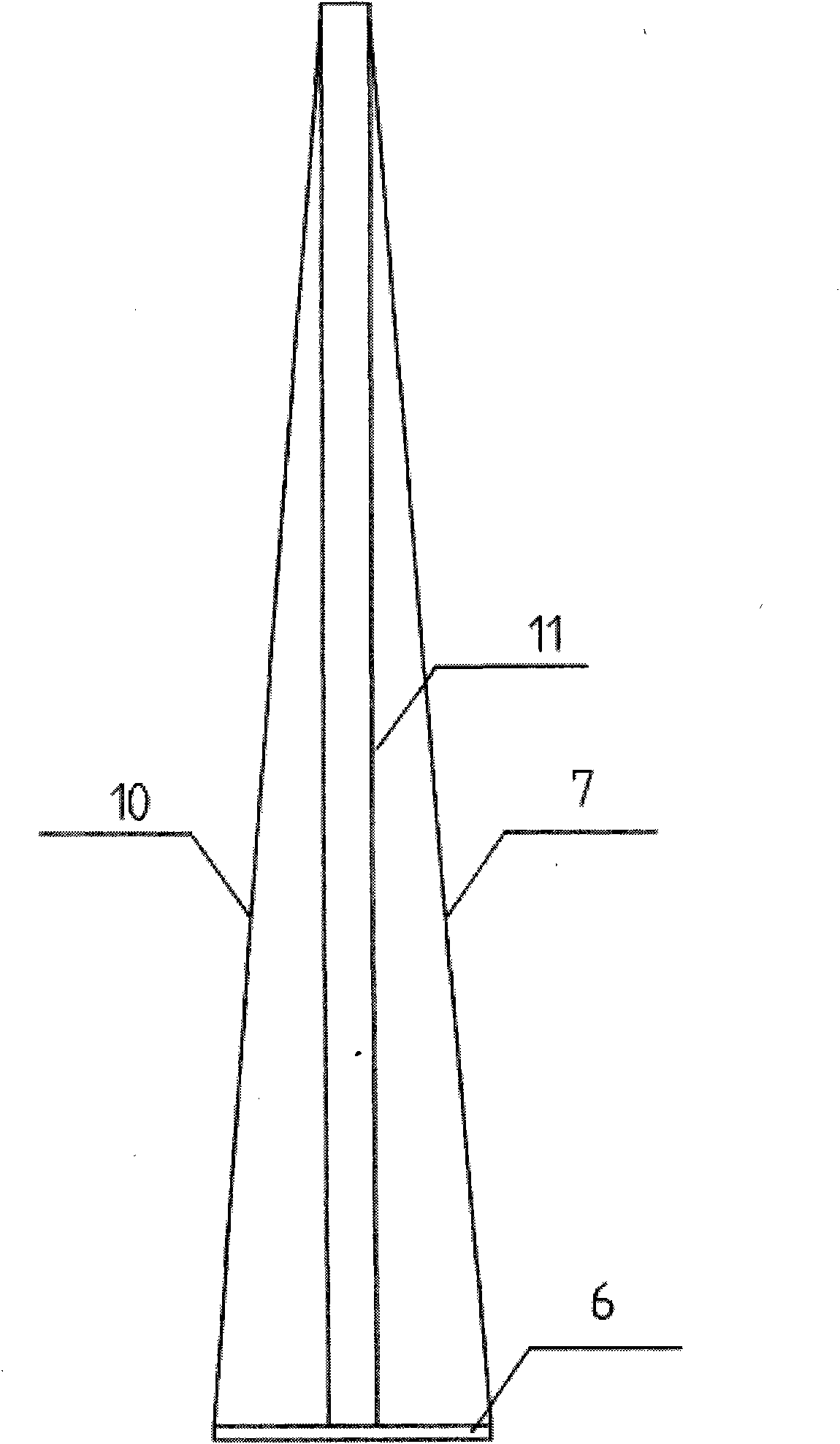

[0022] The present invention is made up of base 6, tension line II 7, tension line I 10 and upper assembly 11, wherein upper assembly 11 is affixed to base 6 through the lower rib 5 thereon; tension line I 10 and tension line The lower ends of the II 7 are respectively affixed to both sides of the base 6, the upper end of the tension line I 10 is affixed to the upper end of one side of the symmetrical airfoil cover 1 of the upper assembly 11, and the upper end of the tension line II 7 is connected to the other side of the symmetrical airfoil cover 1. The upper end of the side is fixedly connected; the base 6 is provided with a through hole.

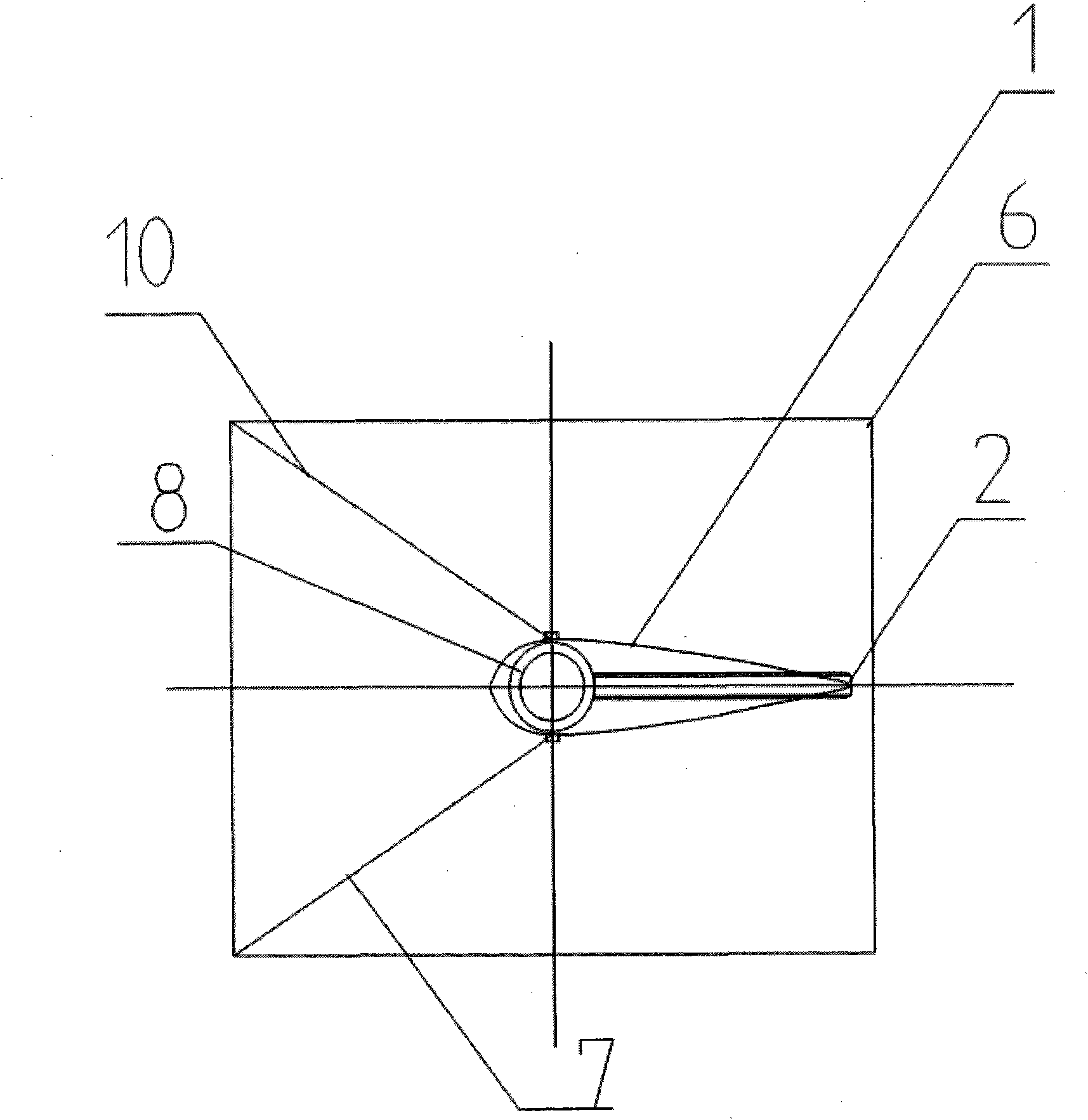

[0023] The upper assembly 11 is composed of a symmetrical airfoil cover 1, a comb-shaped nozzle 2, a middle rib 4, a lower rib 5, a column tube 8 and an upper rib 9, wherein the side wall of the column tube 8 is provided with equidistant through holes, Each through hole is fixedly connected to and communicated with one end of each comb-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com