Multifunctional delivery process of cigarette finished products

A multi-functional and finished product technology, applied in the direction of instruments, data processing applications, logistics, etc., can solve the problems of waste of resources, single application function of equipment, single operation function, etc., and achieve long working distance, powerful functions, and diversified delivery modes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

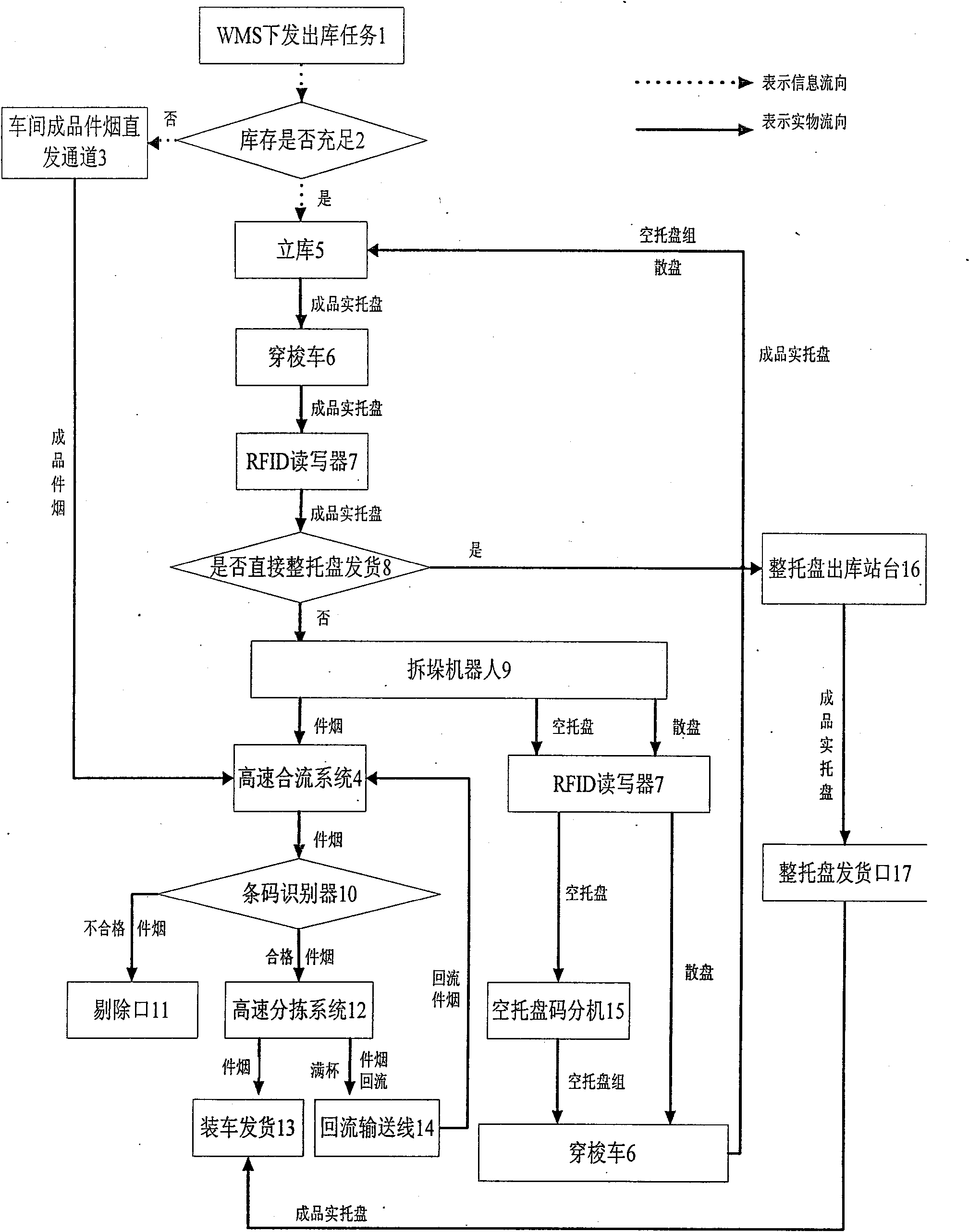

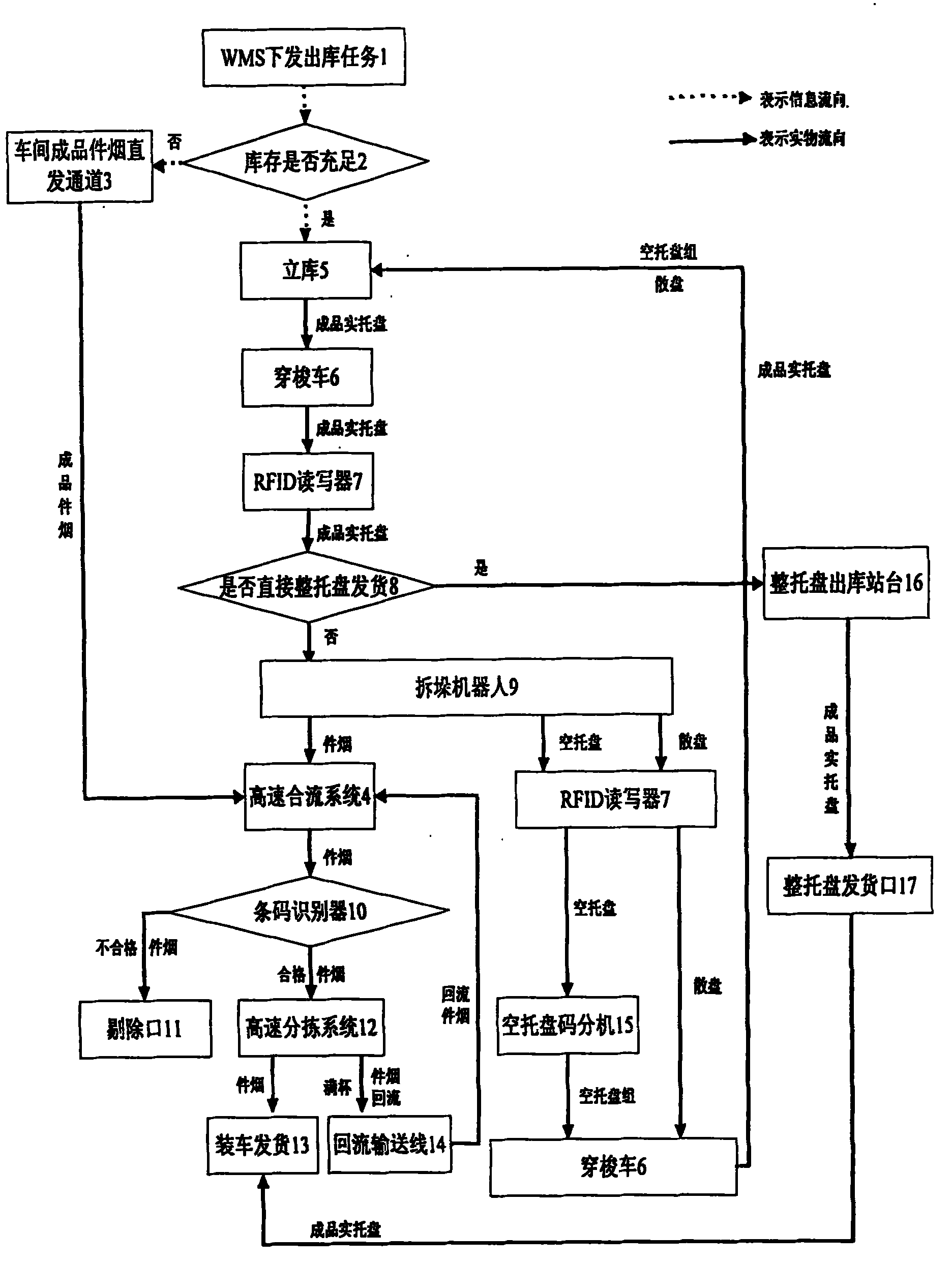

[0018] Such as figure 1 As shown, when it is necessary to ship out of the warehouse, the WMS will send out the warehouse task 1. At this time, it is judged whether the inventory is sufficient. The merge system 4 is merged into the merge main line for sorting and delivery. If the stock is sufficient, the solid tray of finished product cigarettes is transferred out from the vertical storehouse 5. The finished product cigarette pallets transferred out are transported by the shuttle car 6, and the RFID reader 7 reads and writes information on the outgoing cigarette pallets during the transportation process. At this time, it is judged again whether to directly ship the whole pallet or not. If the whole pallet is not shipped, the finished pallet after the information is confirmed is transported to the front end of the unstacking station of the corresponding robot to wait for unstacking. The unstacking robot 9 performs corresponding unstacking actions according to the brand type an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com