Agitation grinder

A grinder and agitator technology, applied in the field of agitator grinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

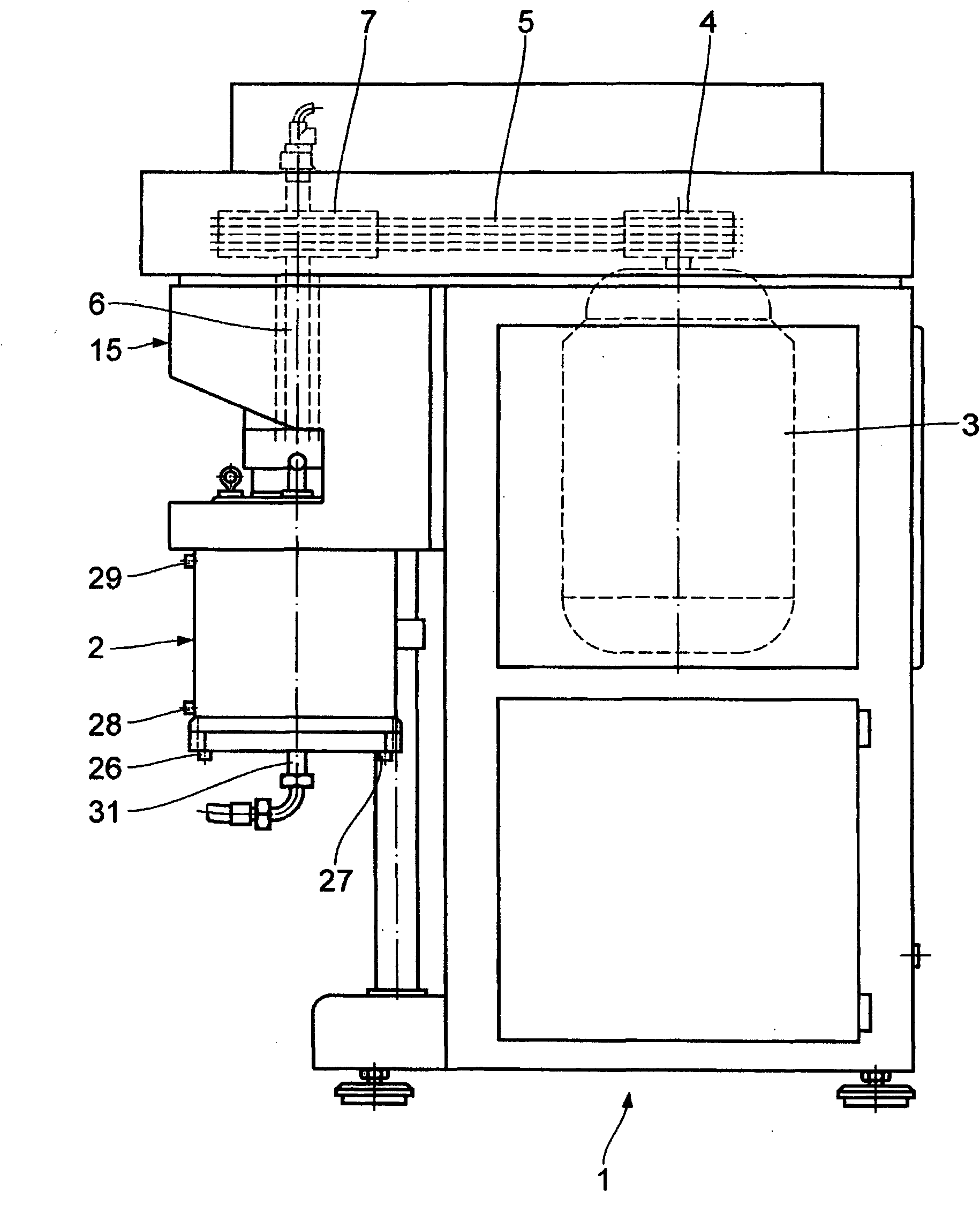

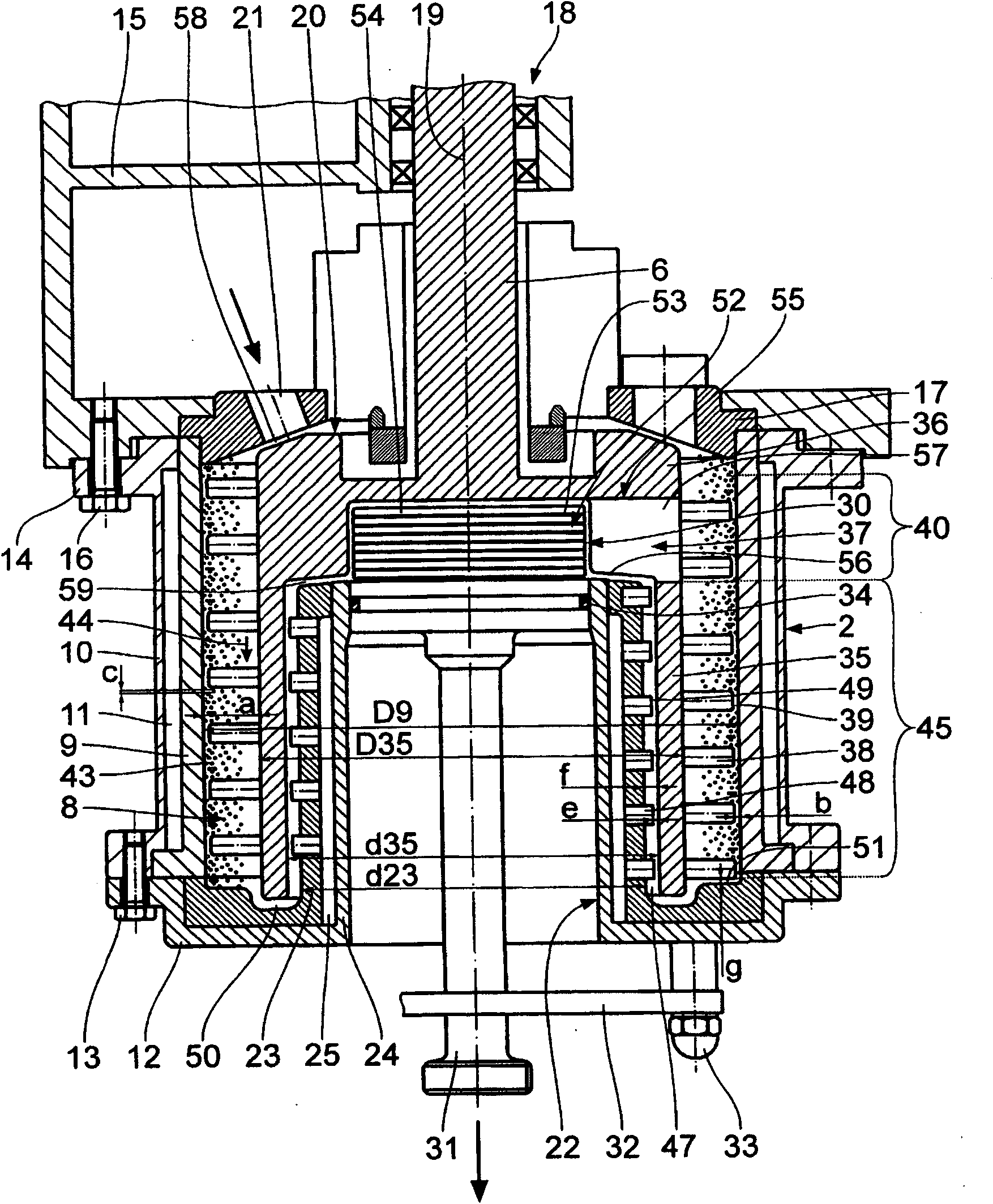

[0026] figure 1 The agitator mill shown in generally has a column 1 on which a cylindrical grinding container 2 can be mounted. In the column 1 is mounted a drive motor 3, which is equipped with a V-belt 4, through which a V-belt 7 is rotatably driven by means of a V-belt 5, which is connected to the drive The shaft 6 is connected in a rotationally fixed manner.

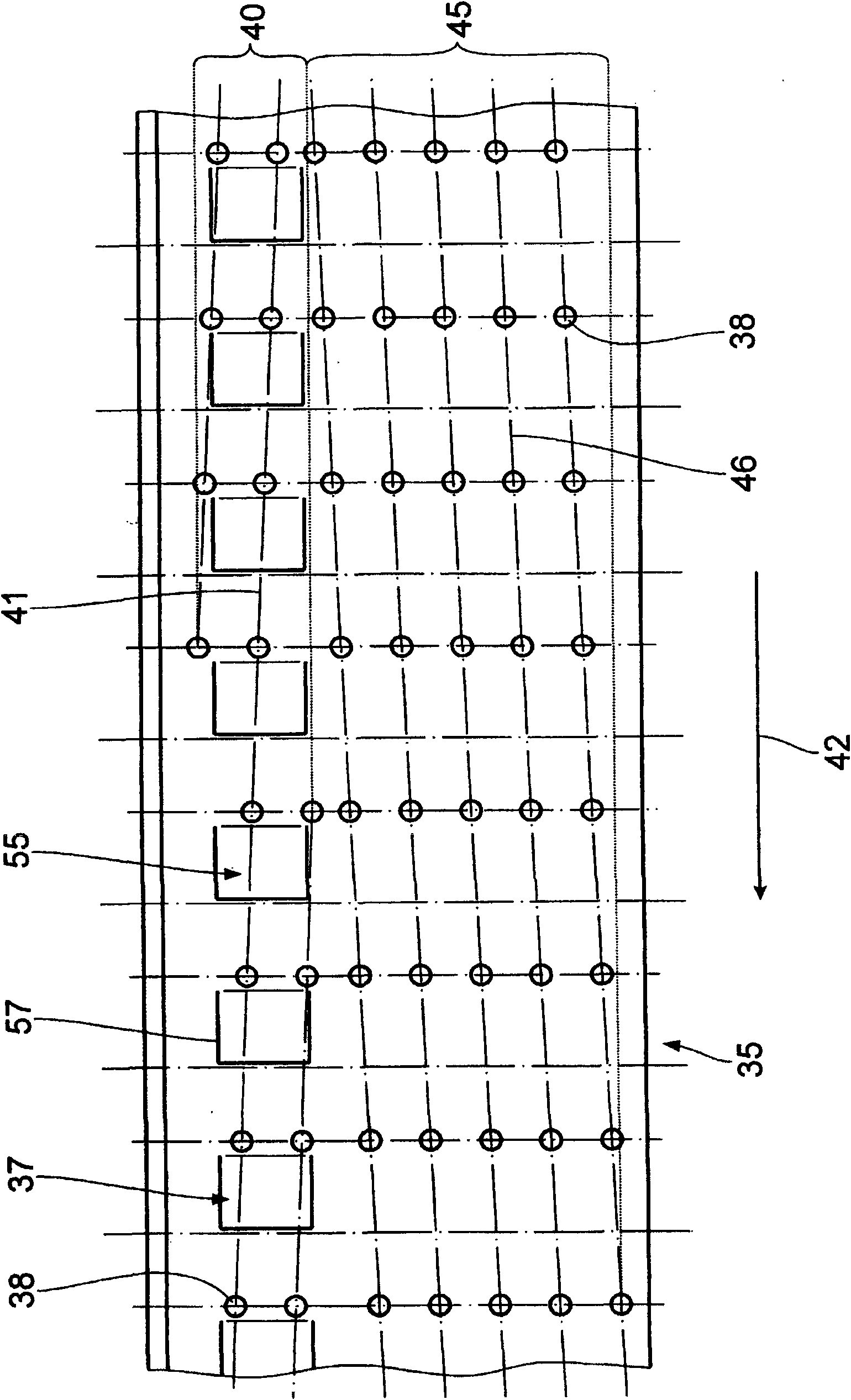

[0027] as in particular by figure 2 and 3 It can be seen that the grinding container 2 has a cylindrical container wall 9 surrounding the grinding chamber 8 , which is surrounded by an essentially cylindrical cooling housing 10 . A cooling chamber 11 is formed between the container wall 9 and the cooling housing 10 . The lower end of the grinding chamber 8 is formed by an annular bottom plate 12, which is fixed on the grinding container 2 with screws 13.

[0028] The grinding container 2 has an upper annular flange 14, by means of which it is fastened with screws 16 to the bottom of a support housing 15 mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com