Ratchet wrench

A ratchet wrench and gear technology, applied in the field of wrenches, can solve the problems of difficult control, the ratchet wrench is not very obvious, etc., and achieve the effects of simple structure, easy control and use, and easy assembly and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

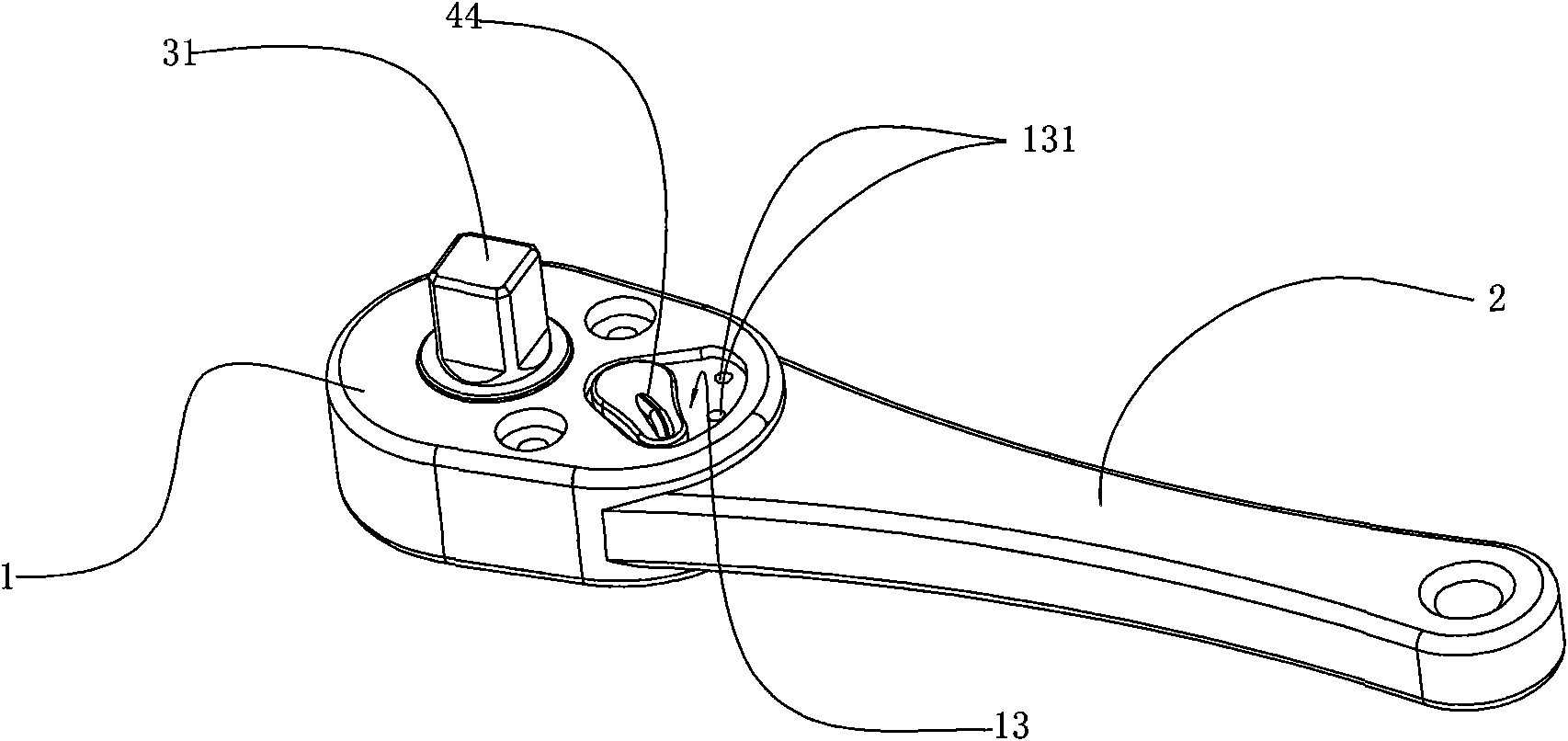

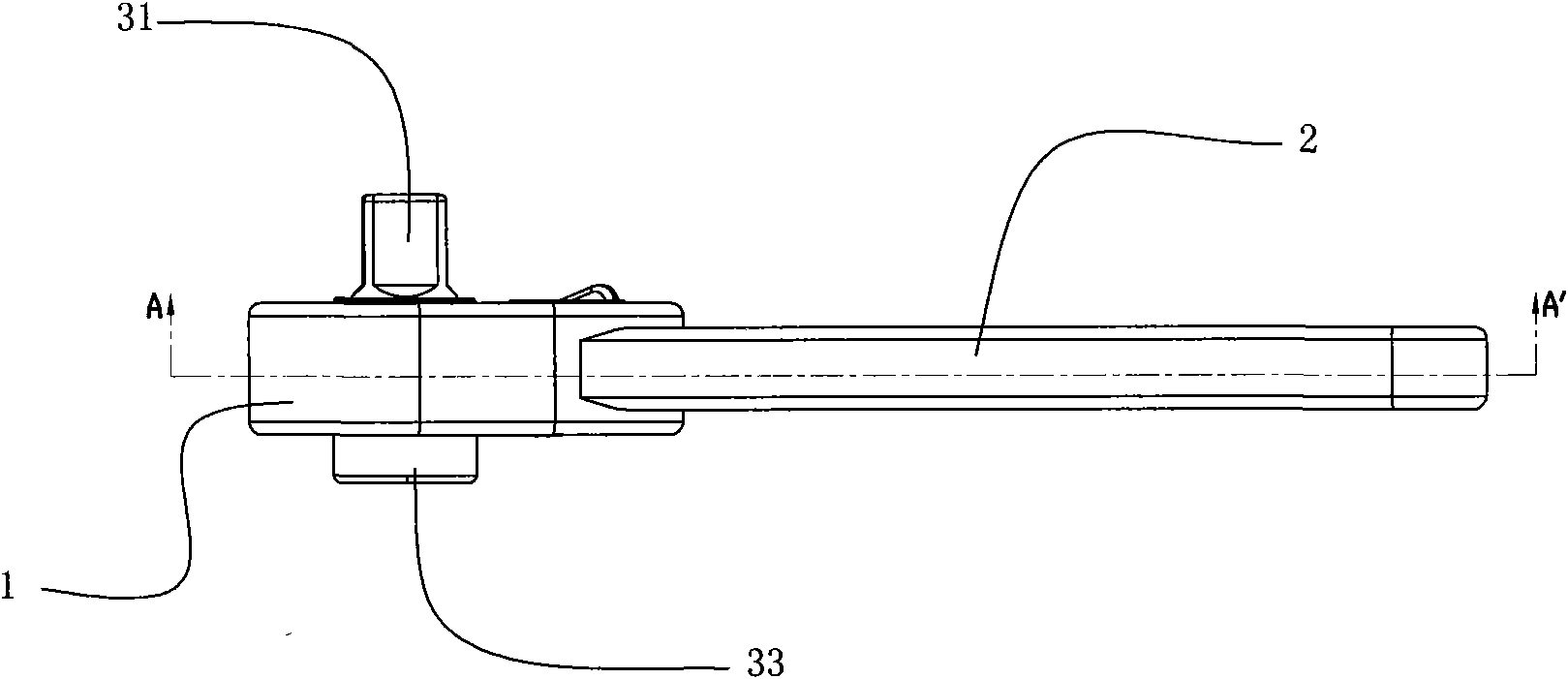

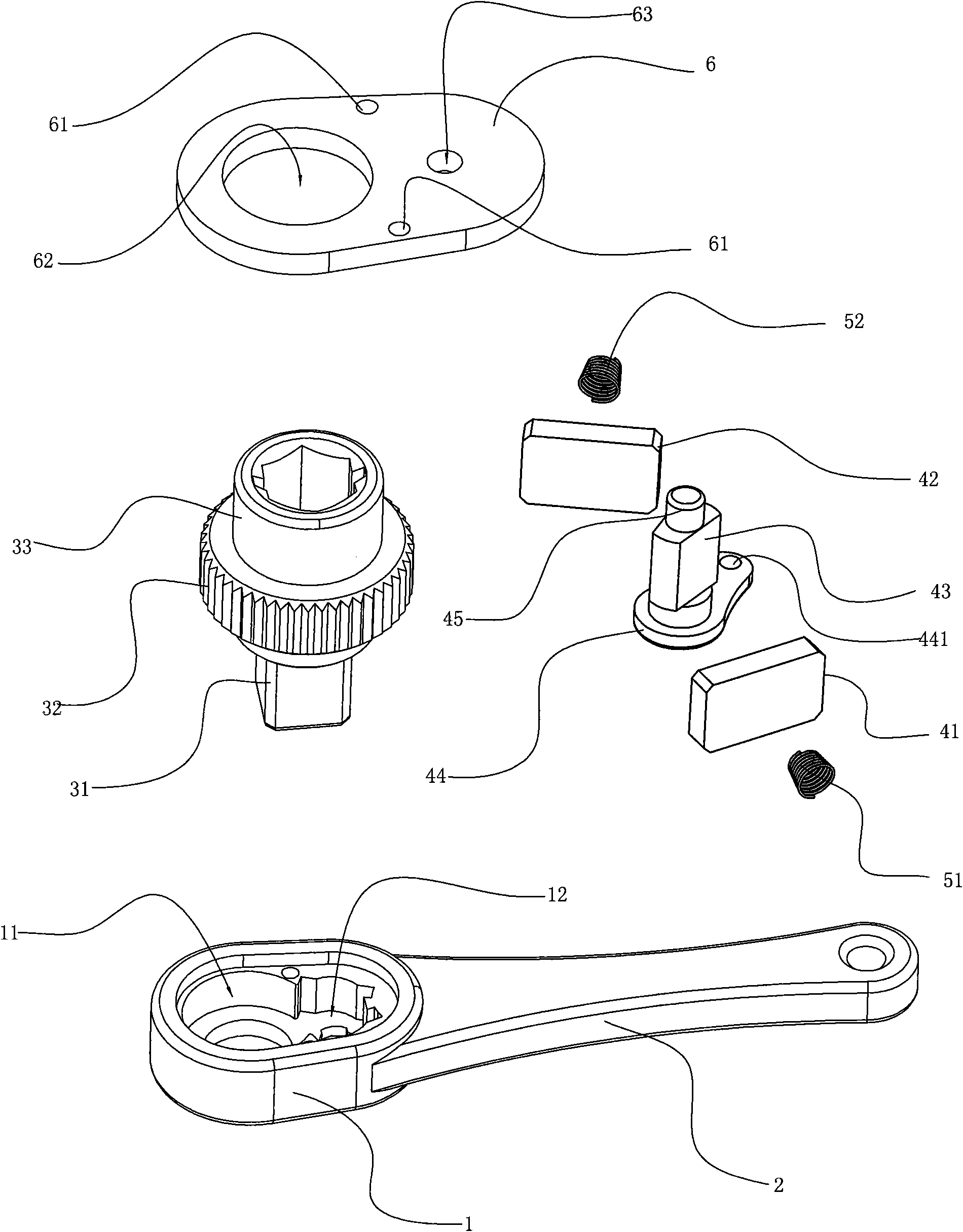

[0021] Ratchet wrench of the present invention, as Figure 1-5 As shown, it includes the head 1 of the wrench and the handle part 2 connected with the head 1. The head 1 has a through hole 11 for accommodating the gear assembly, and the bottom 31 of the gear assembly protrudes from the through hole 11. The gear part 32 of the gear assembly is placed in the step of the through hole 11, and the top of the gear part 32 has a connecting head 33 protruding from the head 1 of the wrench. The connecting head 33 can have holes of various shapes for Connect external nuts or bolts. The bottom 31 of the gear assembly protruding from the head 1 can also be a cube. The shape of the bottom 31 can be designed to connect sockets of different sizes to become a socket wrench. The sockets of different sizes can be suitable for connecting external objects of dif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap