Umbrella leaf repair device of silicone rubber composite bushing

A composite casing and silicone rubber technology is applied in the field of the silicone rubber composite casing umbrella blade repairing device, which can solve the problems of waste of rubber material, high technical requirements of workers, and difficulty in guaranteeing the success rate, so as to reduce losses, save costs, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

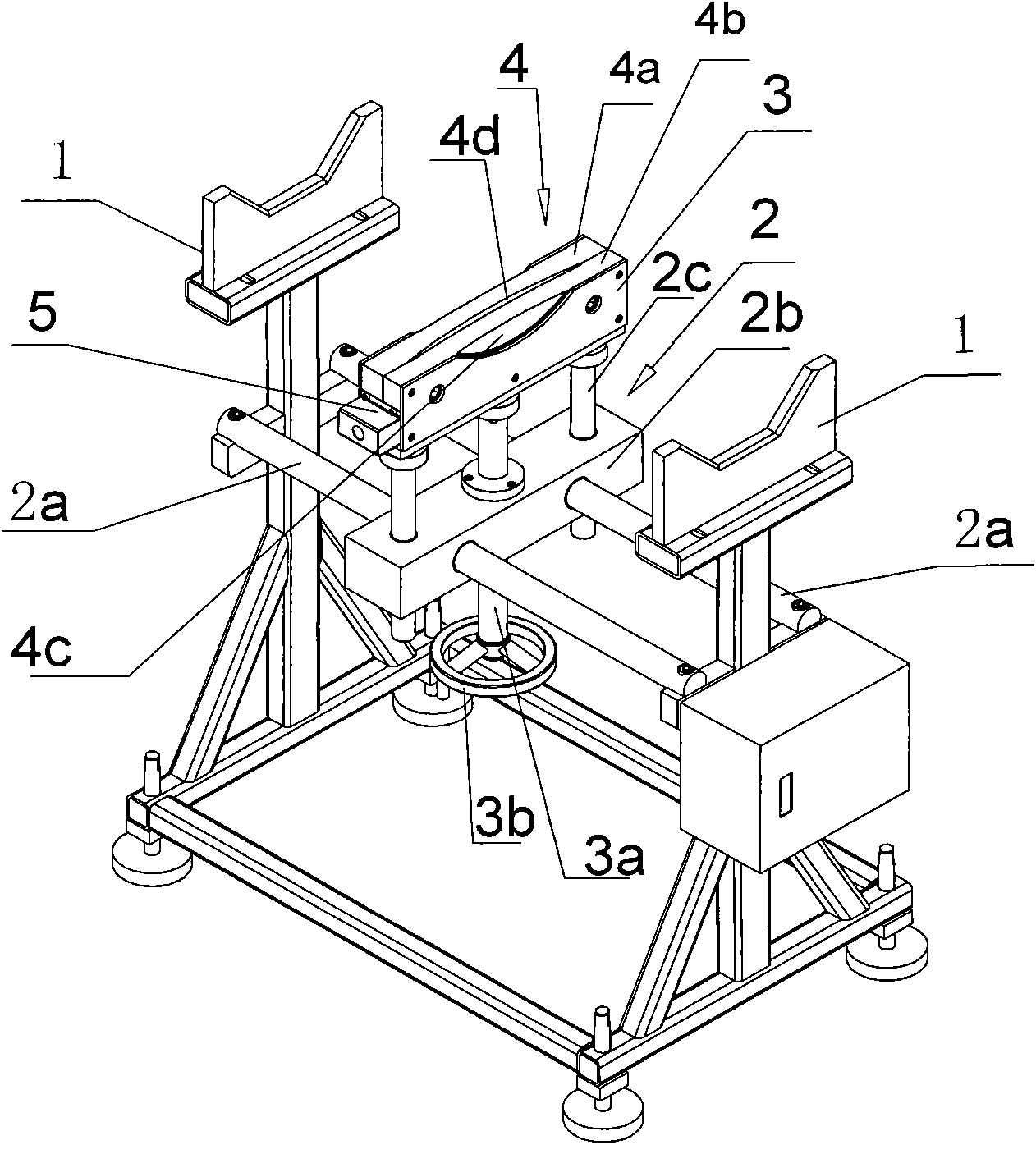

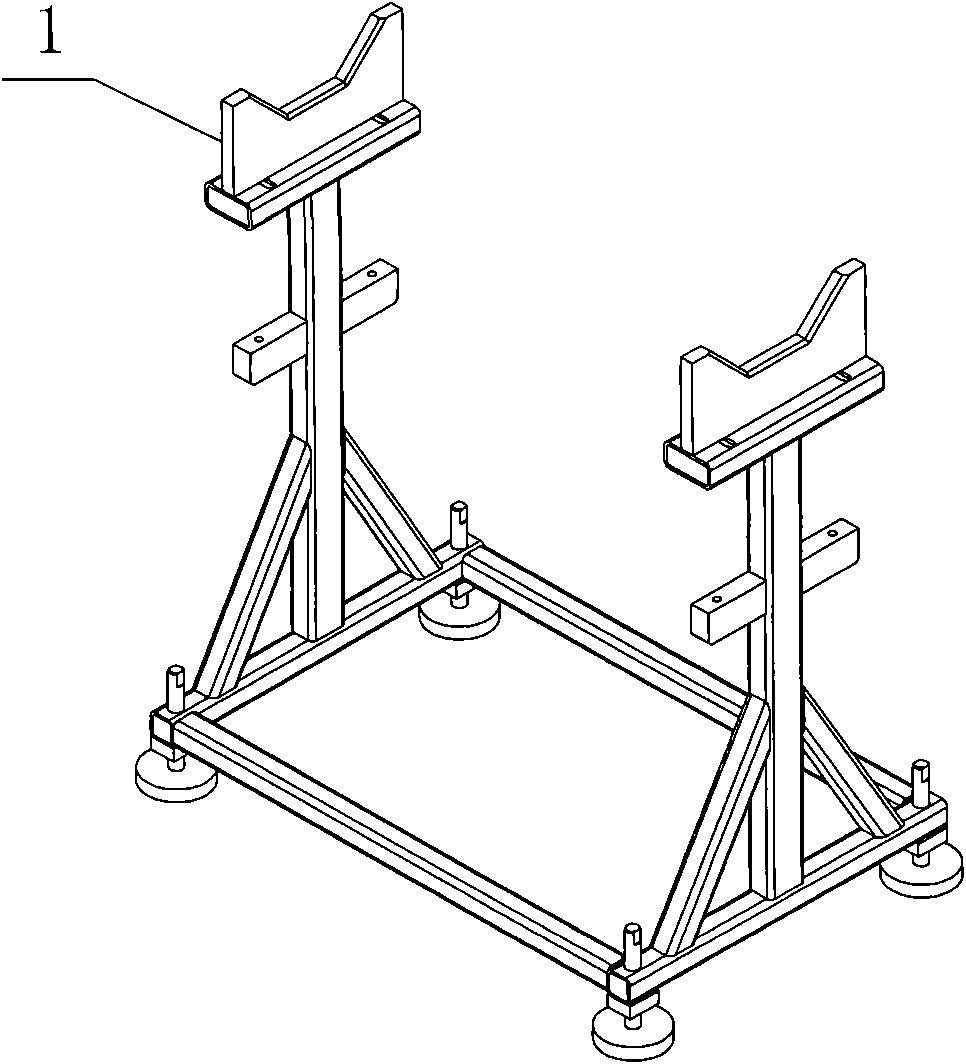

[0034] refer to Figure 1 to Figure 11 As shown, a silicone rubber composite casing umbrella leaf repair device of the present invention includes a bracket 1 for positioning the composite casing A, a lifting and horizontal sliding mechanism 2 between the brackets 1, a mold base 3, and a repair insert 4. The formwork 3 is set on the lifting and horizontal sliding mechanism 2, which can be adjusted by lifting and horizontal sliding. The repair insert 4 is set on the formwork 3 and is opposite to the composite sleeve positioned on the bracket 1. The repair insert 4 A repairing cavity 4d and a heating device 5 for heating and repairing the cavity 4d are provided, and the repairing cavity 4d is adapted to the composite casing umbrella leaf.

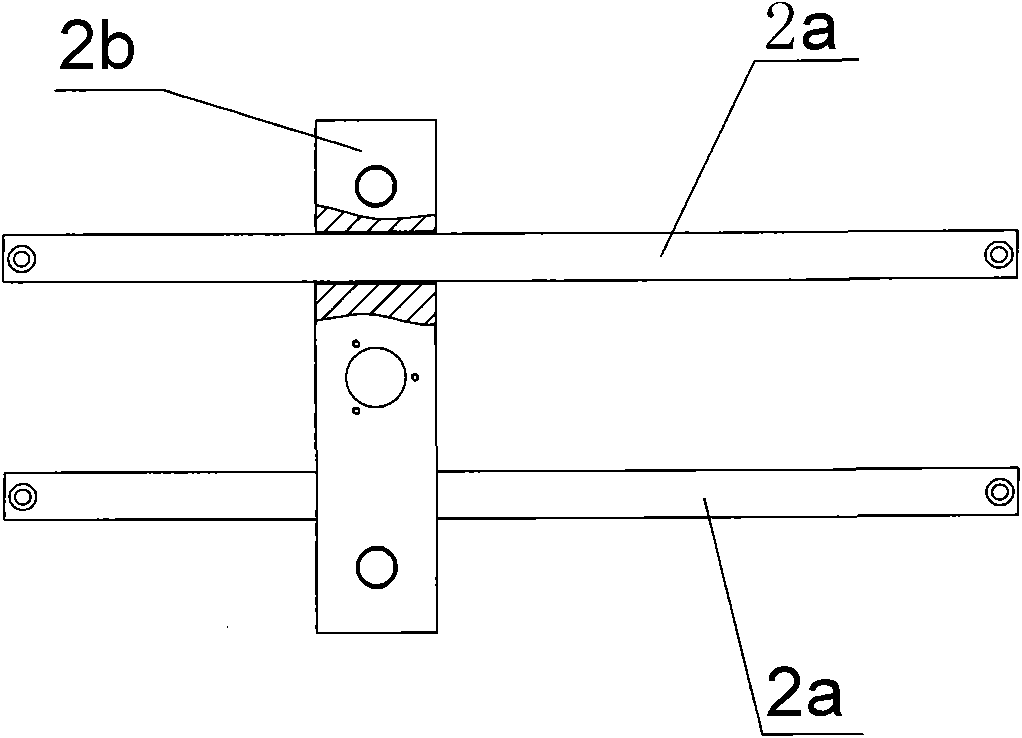

[0035] The lifting and horizontal sliding mechanism 2 includes a horizontal guide rod 2a, a sliding seat 2b, and a vertical guide post 2c. Lifting vertically, the formwork 3 is fixed on the vertical guide post 2c.

[0036] A lifting adjustme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap