New preparation method of herbicide glyphosate

A solvent and new process technology, which is applied in the new field of herbicide glyphosate preparation, can solve the problems of polluting the environment and increasing production costs, and achieve the effects of reducing production costs, reducing waste water discharge, and reducing waste gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

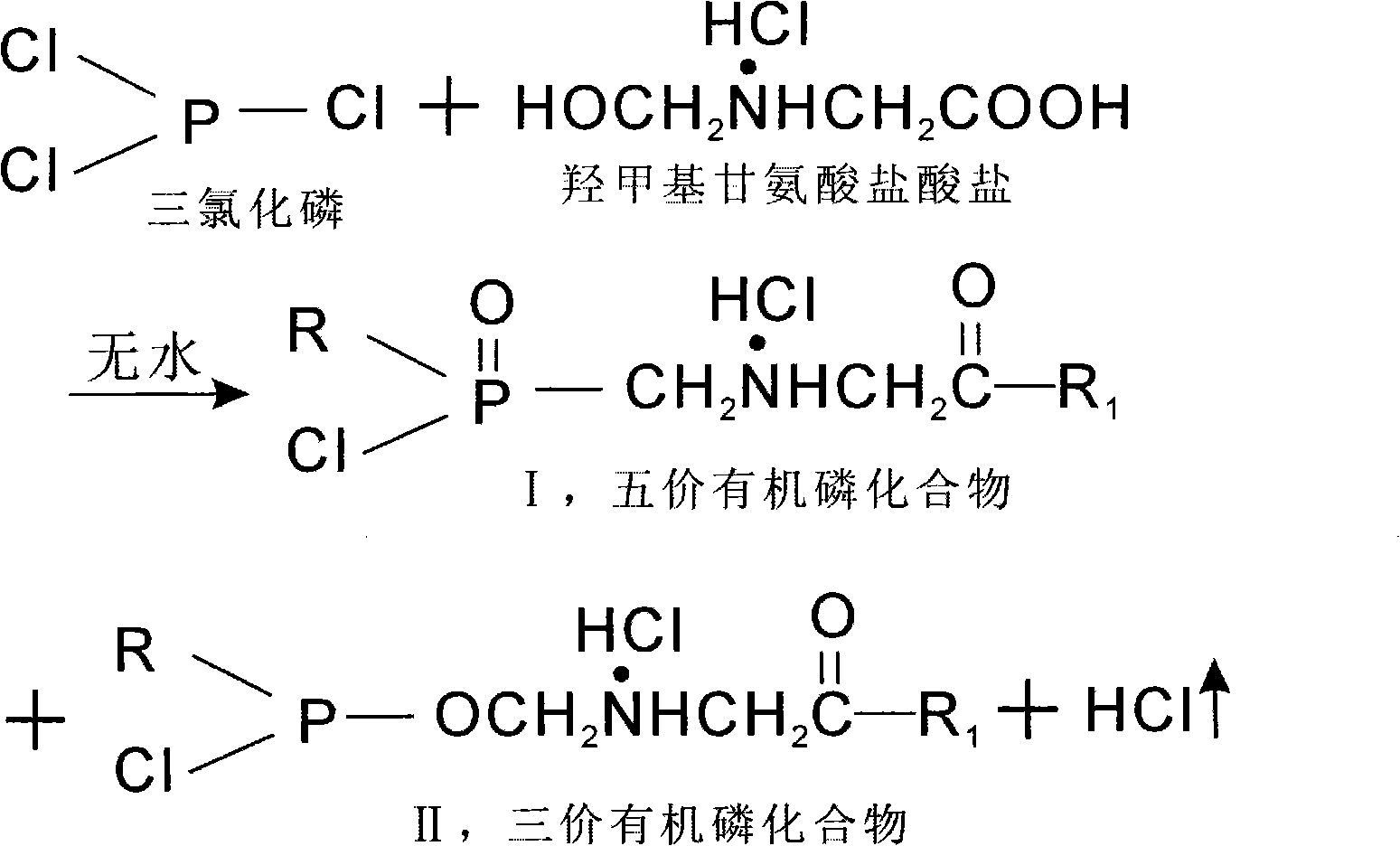

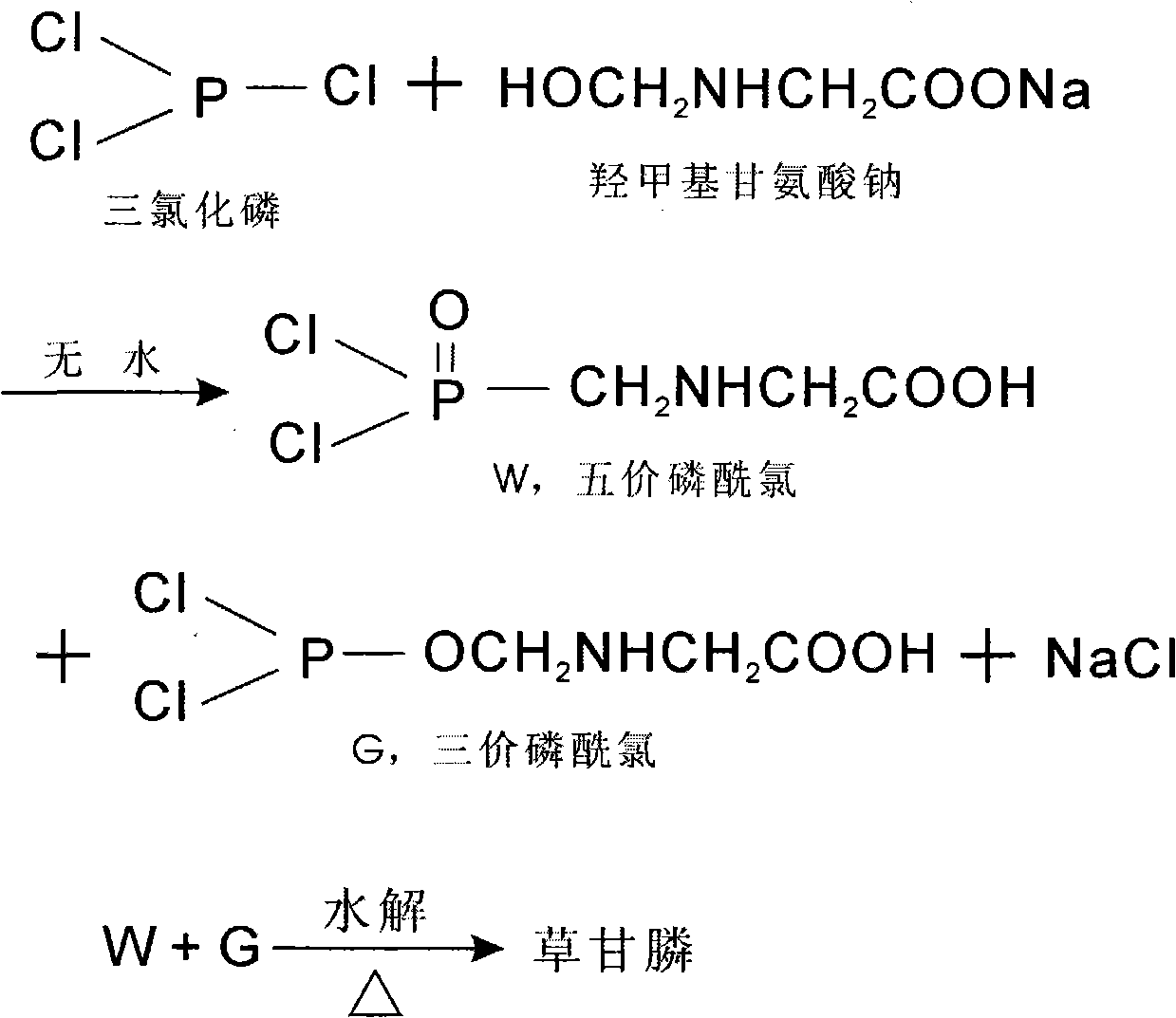

Method used

Image

Examples

Embodiment 1

[0060] Molecular ratio: glycine: formaldehyde: hydrochloric acid: phosphorus trichloride = 1:2:2:1.02~1.05

[0061] Put 100 grams of 95% glycine and 304 grams of 30% hydrochloric acid into a four-necked reaction bottle at one time, start stirring, control the temperature at about 60°C, and add 211 grams of 36% formaldehyde dropwise. Turn on the vacuum and distill water, hydrochloric acid and formaldehyde as much as possible at 60 ° C. The distillation substrate is hydroxymethylglycine hydrochloride. Then, add 30 grams of N,N-dimethylformamide solvent at room temperature, and add to the distillation substrate Slowly add 181 grams of 98% phosphorus trichloride dropwise, control the temperature at about 74°C and keep it warm for 2 hours, then under high vacuum, try to distill off the solvent and excess phosphorus trichloride, and the distillation substrates are I and II Then, slowly add 80 grams of pure water under normal pressure, control the temperature at 90-110°C, hydrolyze f...

Embodiment 2

[0063] Molecular ratio: sodium hydroxymethylglycine: phosphorus trichloride = 1: 1 ~ 1.02

[0064] Put 100 grams of 98% phosphorus trichloride and 145 grams of N,N-dimethylformamide into the reaction bottle at one time, start stirring, control the temperature at about 25°C, and slowly add anhydrous sodium hydroxymethylglycinate solid 165 gram, keep warm for 1 to 2 hours, then, at about 20°C, filter out the NaCl solid generated, filter the mother liquor and return to the reactor, turn on the vacuum, and try to evaporate the N,N-dimethylolformamide solvent and excess Phosphorus trichloride, the distillate can be applied mechanically, and the distillation substrate is the new compound mixture of W and G. Then, under normal pressure, add 100 grams of water to the distillation substrate, control the temperature at 60-110°C, and perform the hydrolysis reaction for 2 ~8 hours, then, turn on the vacuum, distill hydrochloric acid and water as far as possible, the distillation substrate...

Embodiment 3

[0066] Molecular ratio: glycine: formaldehyde: HCl: phosphorus trichloride = 1:2~4:0~1:1

[0067] Put 100 grams of 95% glycine and 100 grams of pure water into the reaction bottle at one time, start stirring, control the temperature at about 60°C, and observe the transparency of the reaction system, then slowly add 317 grams of 36% formaldehyde dropwise, and keep the temperature for 4 hours. Turn on the vacuum, steam out water as much as possible, steam out excess hydrochloric acid and excess formaldehyde, and the distillation substrate is N, N——dimethylolglycine. Then, add 50 grams of anhydrous ethyl acetate to the distillation substrate, control the temperature at about 40°C, slowly add 177 grams of 98% phosphorus trichloride dropwise, keep the reaction for 1 hour, and then under high vacuum, try to distill out Solvent and excess phosphorus trichloride, the distillation substrate is the new compound mixture of C and D, 280 grams of 60% methanol aqueous solution is added to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com