Semi-automatic electrically controlled clutch system

A clutch and semi-automatic technology, applied in the direction of magnetic drive clutch, non-mechanical drive clutch, clutch, etc., can solve the problems of high price, development impact, high maintenance cost and fuel consumption, and achieve easy maintenance, simplified gear operation and reduced fuel consumption and production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

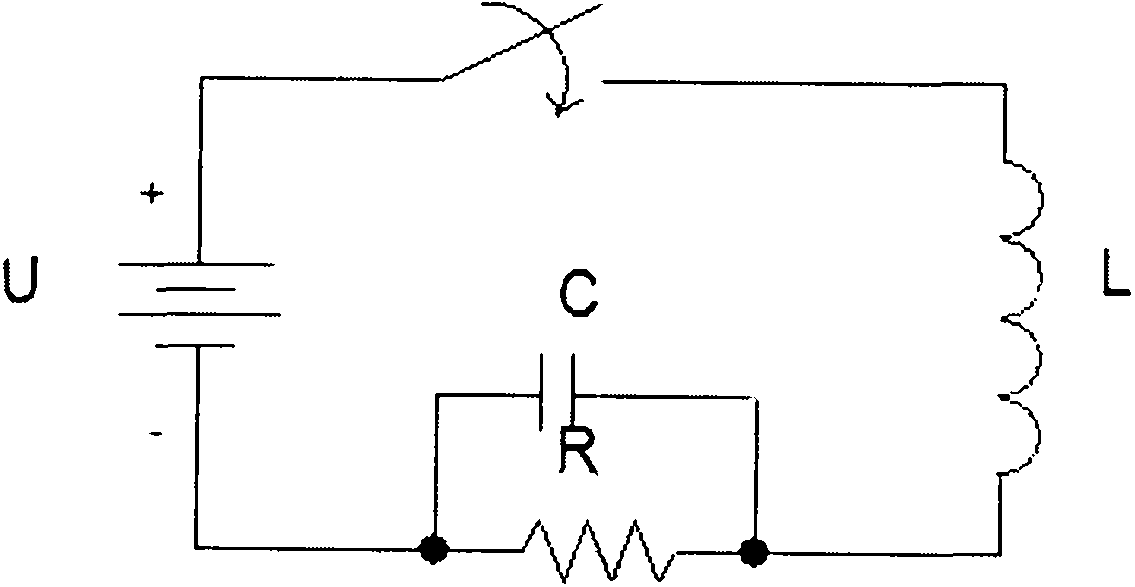

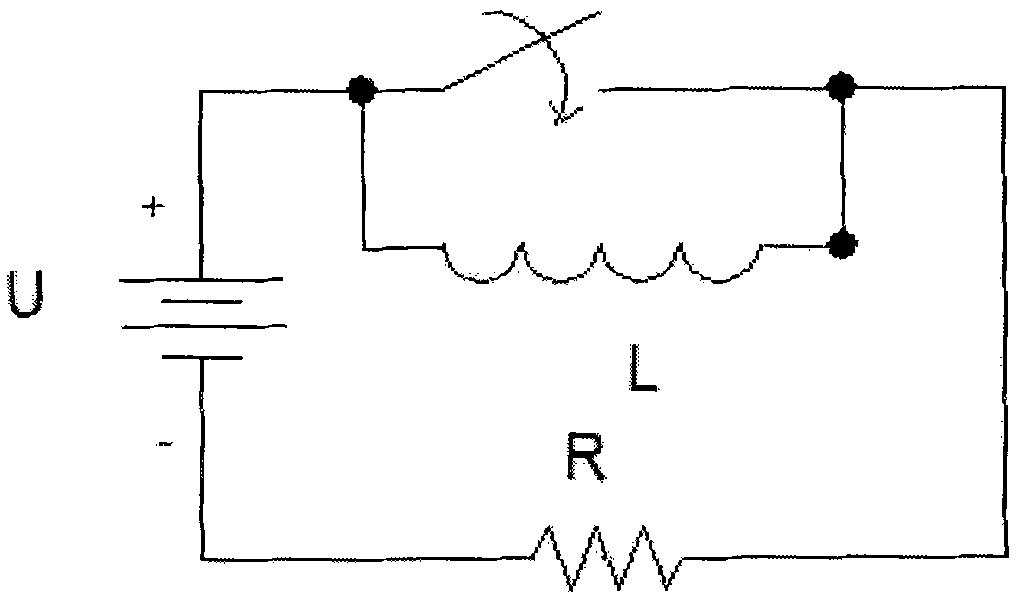

[0031] Such as Figure 7 As shown, a semi-automatic electronically controlled clutch system includes a DC solenoid electromagnet 3, a control circuit 2 for controlling the current on and off of the DC solenoid electromagnet 3, and the control circuit 2 is connected to the transmission lever 1 of the gearbox, the steering wheel 5 and the car key. The sockets are respectively provided with switches, and the armature 301 of the DC coil electromagnet 3 is fixedly connected with the lever 7a at one end of the hydraulic control mechanism 4. The other end of the hydraulic control mechanism 4 is connected with the clutch through the lever 7b. The rated stroke of the armature 301 is 10cm, and the adsorption force of the stop iron 302 of the DC solenoid electromagnet 3 to the armature 301 is 25g (g is the acceleration of gravity) under this rated stroke.

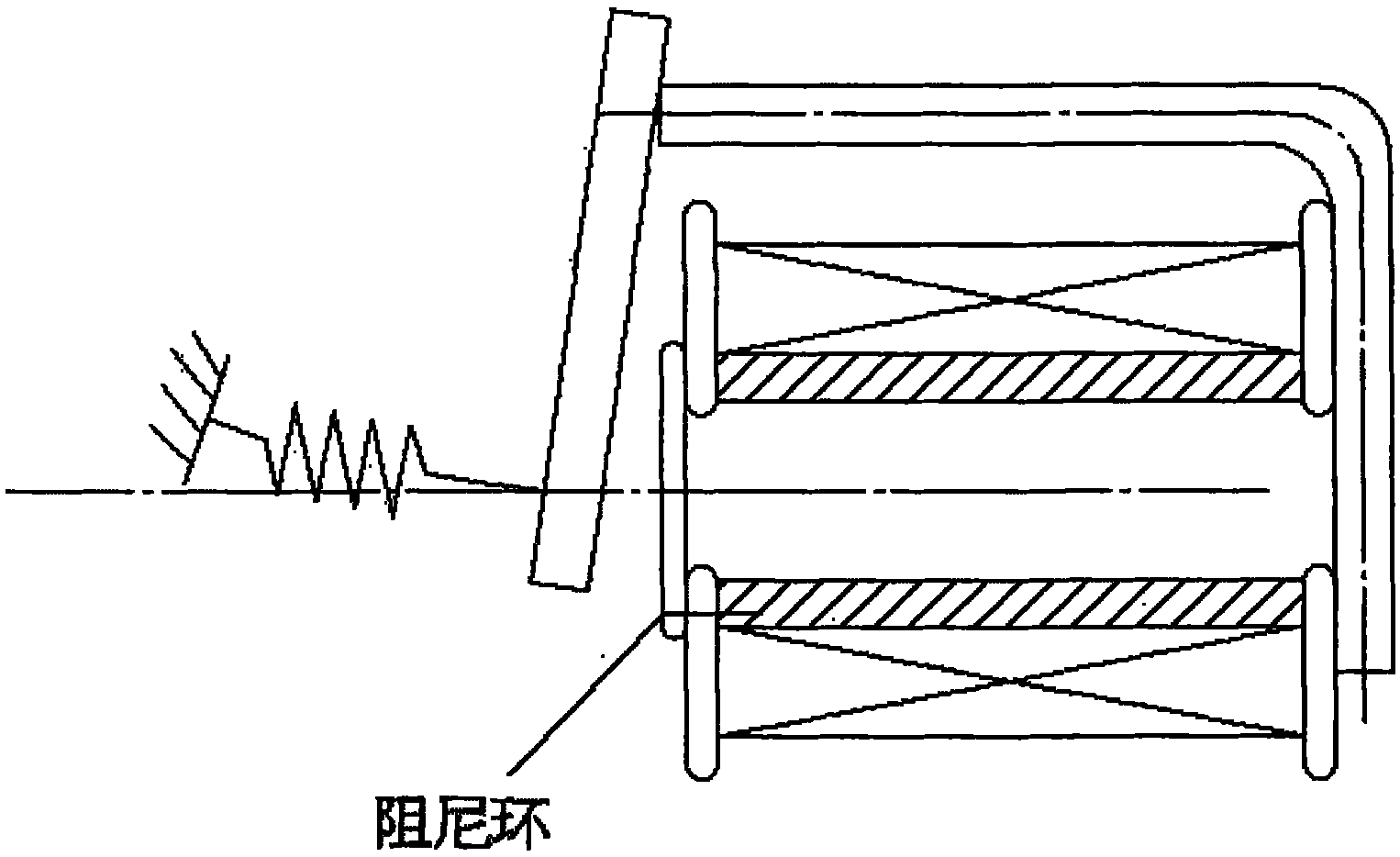

[0032] Such as Figure 8 As shown, the DC spiral tube electromagnet 3 adopts the product MQ8-DC70290 of Wuxi Hydraulic Complete Tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com