Hemispherical garlic peeler

A hemispherical, garlic machine technology, applied in home appliances, peeling appliances, applications, etc., can solve problems such as labor-intensive, affect the effect of peeling garlic, and difficult to separate garlic petals and garlic skins, and achieve the effect of reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

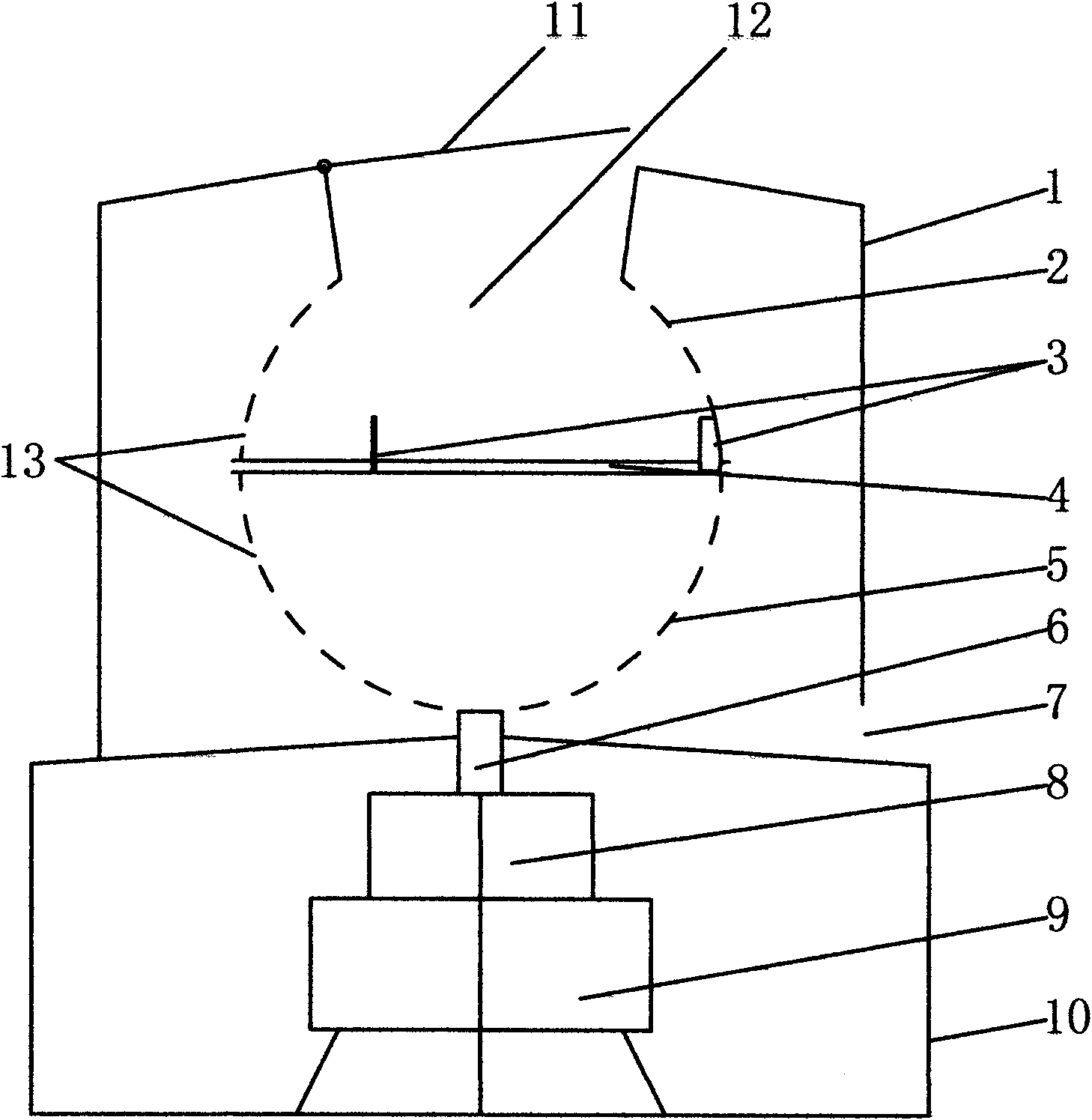

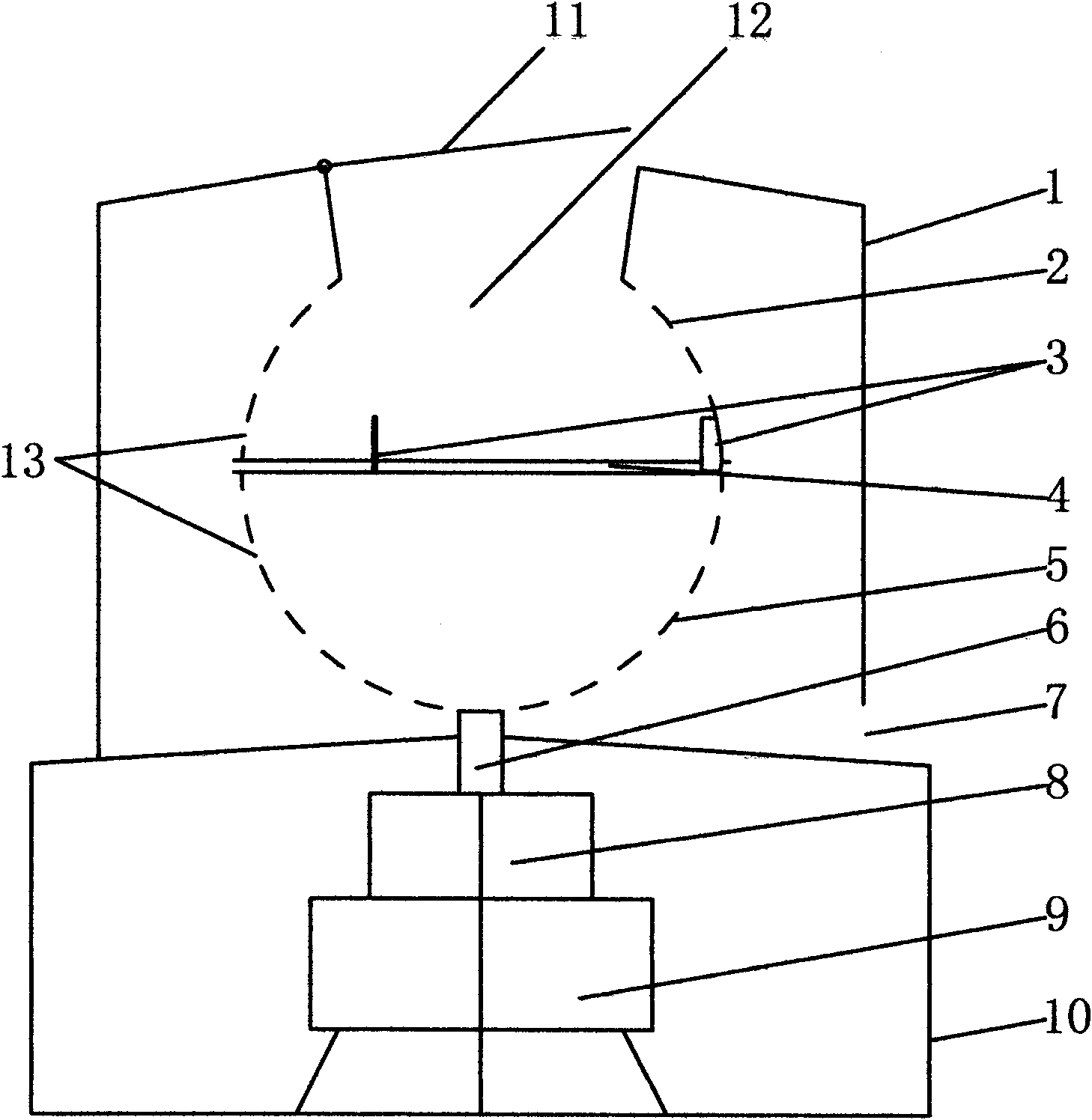

[0016] A hemispherical garlic peeling machine includes a motor 9, a rotating shaft 6, and a garlic peeling bucket 5. The garlic peeling bucket 5 is in a hemispherical shape. The garlic peeling bucket 5 is provided with a garlic cover 2, a garlic peeling bucket 5 and a garlic cover 2 is provided with a gap 4, the top of the garlic cover 2 is provided with an inlet and outlet 12, the lower part of the garlic peeling bucket 5 is fixedly connected with the rotating shaft 6, and the walls of the garlic peeling bucket 6 and the garlic cover 2 are provided with Hole 13 is provided with a garlic peeling barrel guard 1 outside the garlic peeling barrel 5 and the garlic cover 2; a motor shield 10 is provided under the garlic peeling barrel guard 1, and a lower wall of the garlic peeling barrel guard 1 is provided There is a garlic peel outlet 7; the through holes 13 provided on the walls of the garlic peeling bucket 5 and the garlic cover 2 are strip-shaped gaps; the motor 9 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com