Effort-saving wrench socket and manufacturing method thereof

A technology of a wrench sleeve and a manufacturing method, which is applied in the directions of wrenches, manufacturing tools, wrenches, etc., can solve the problems of uneven occlusal force, broken cylinder body, large power consumption, etc., and achieves reasonable gear clearance and increased bending strength. , the effect of structural strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

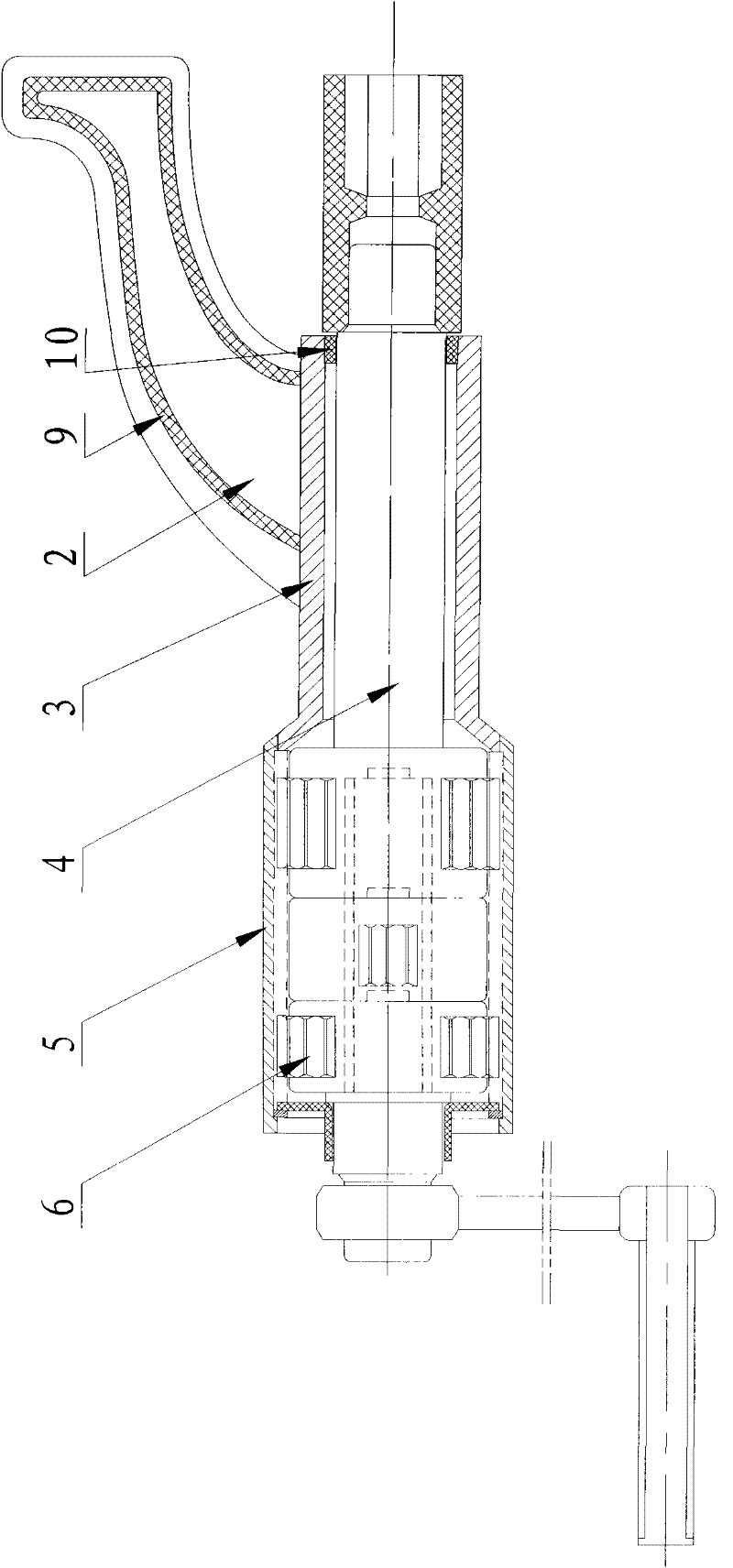

[0031] The overall structure of this embodiment is as figure 1 , 3 , 4, wherein the sleeve body is arranged on the outer periphery of the planetary carrier gear set 6, the lower part of its inner wall forms a transmission pair with the planetary carrier gear set 6, the upper part of the sleeve body is slidably fitted with the front output large bar 4, and the support arm is set on the sleeve The outer wall surface of the cylinder; the support arm adopts a composite frame structure composed of a connecting piece 2 with a reinforcing rib 1 pressed on the surface and a welded inner support frame 9 clamped.

[0032] The manufacturing method of the labor-saving wrench socket comprises the following process steps:

[0033] A. The connecting piece 2 is made of steel plate stamping parts, and then the reinforcement ribs are cold-pressed on the connecting piece 2 with a mold of a large press, and the steel part of the inner support frame is stamped with a steel plate, and then bent in...

Embodiment 2

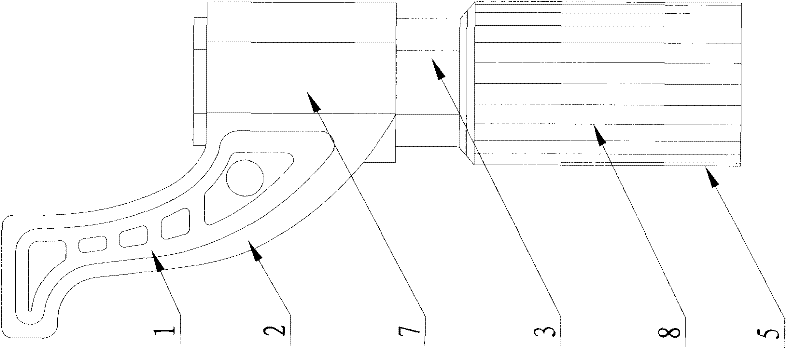

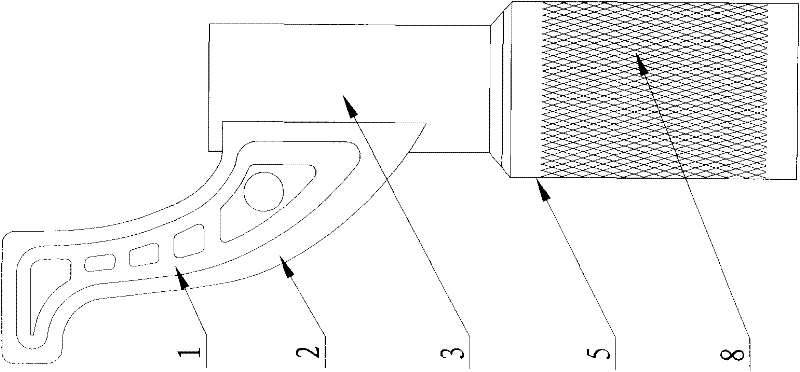

[0043] The structure of the sleeve body of the present embodiment is as figure 2 As shown, the production of the upper sleeve 3 uses the outer square and inner circle pipe as the raw material, the support arm is welded and matched with the sliding sleeve 7, and the sliding sleeve 7 is fitted axially with the surface of the upper sleeve, so that it can be disassembled. The screw nuts at different heights (the screw nuts of other equipment can be disassembled) are multi-purpose labor-saving wrenches that can be adjusted. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com