Battery pack assembly of electric vehicle

A technology for electric vehicles and battery packs, applied in battery pack parts, electric vehicles, electrical components, etc., can solve the problems of short charging cycle, high price, restricting the popularization of electric vehicles, etc., to prolong the charging cycle and improve cost performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

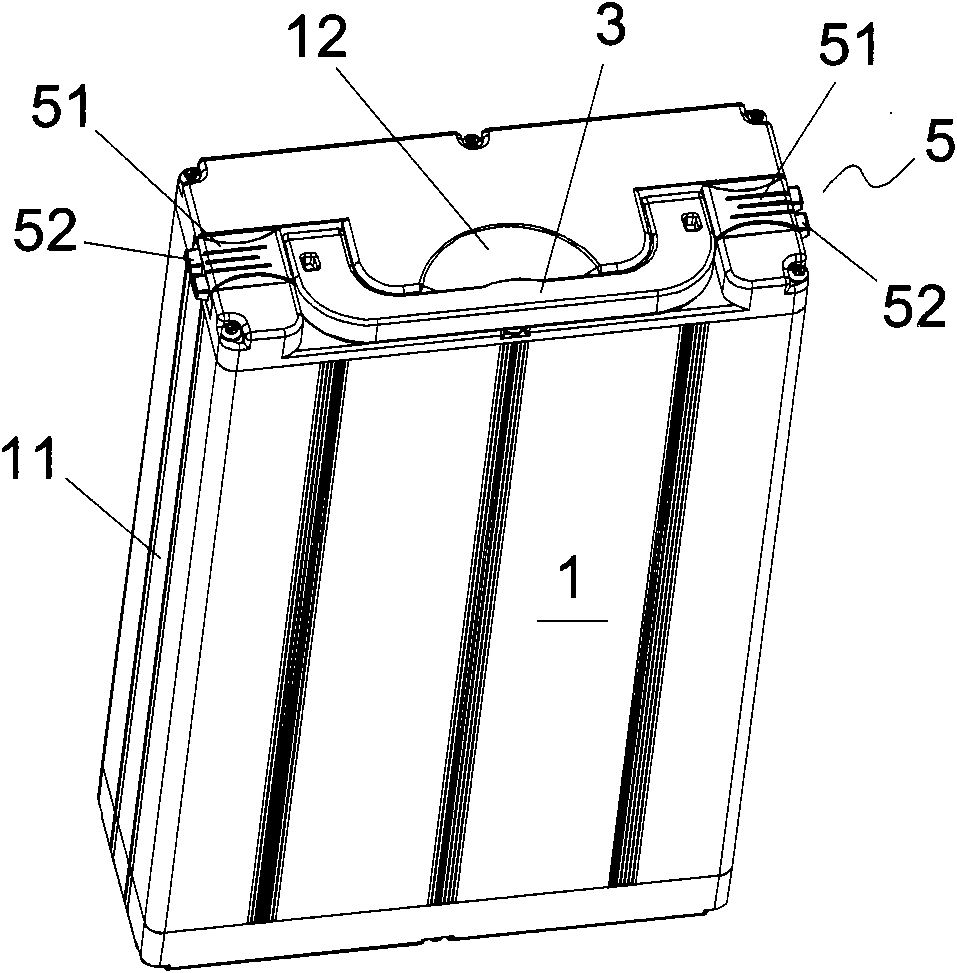

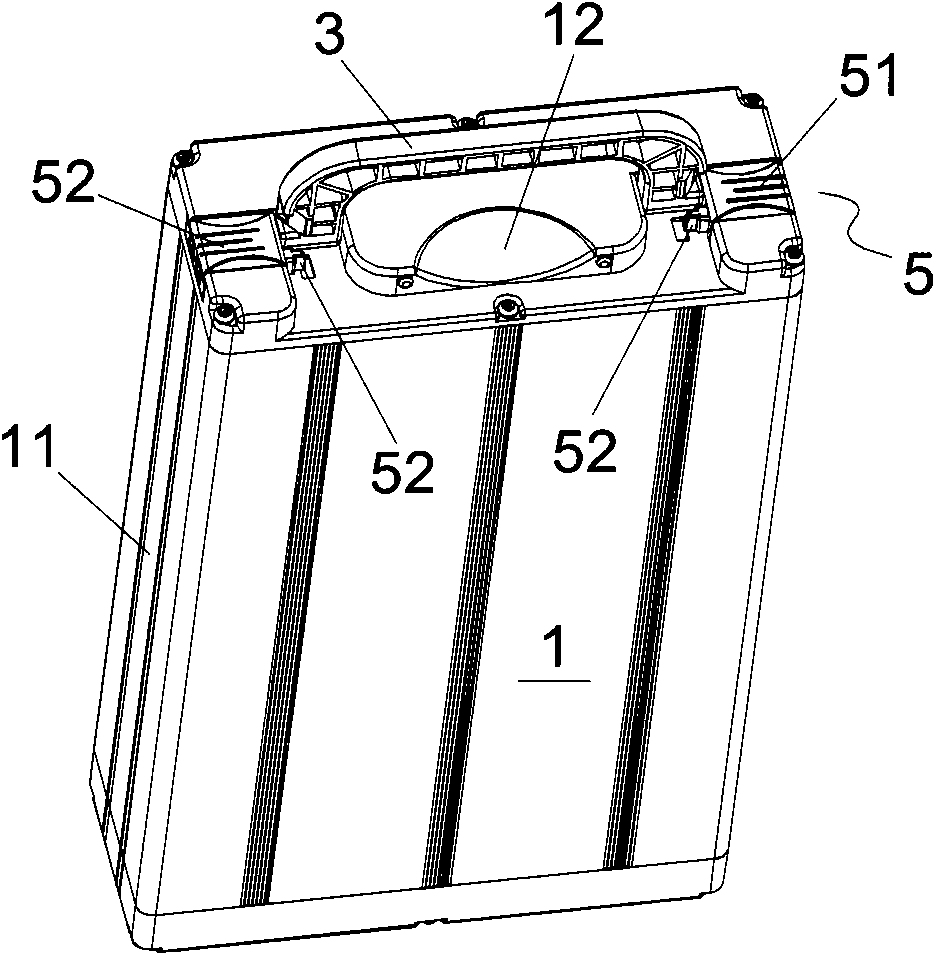

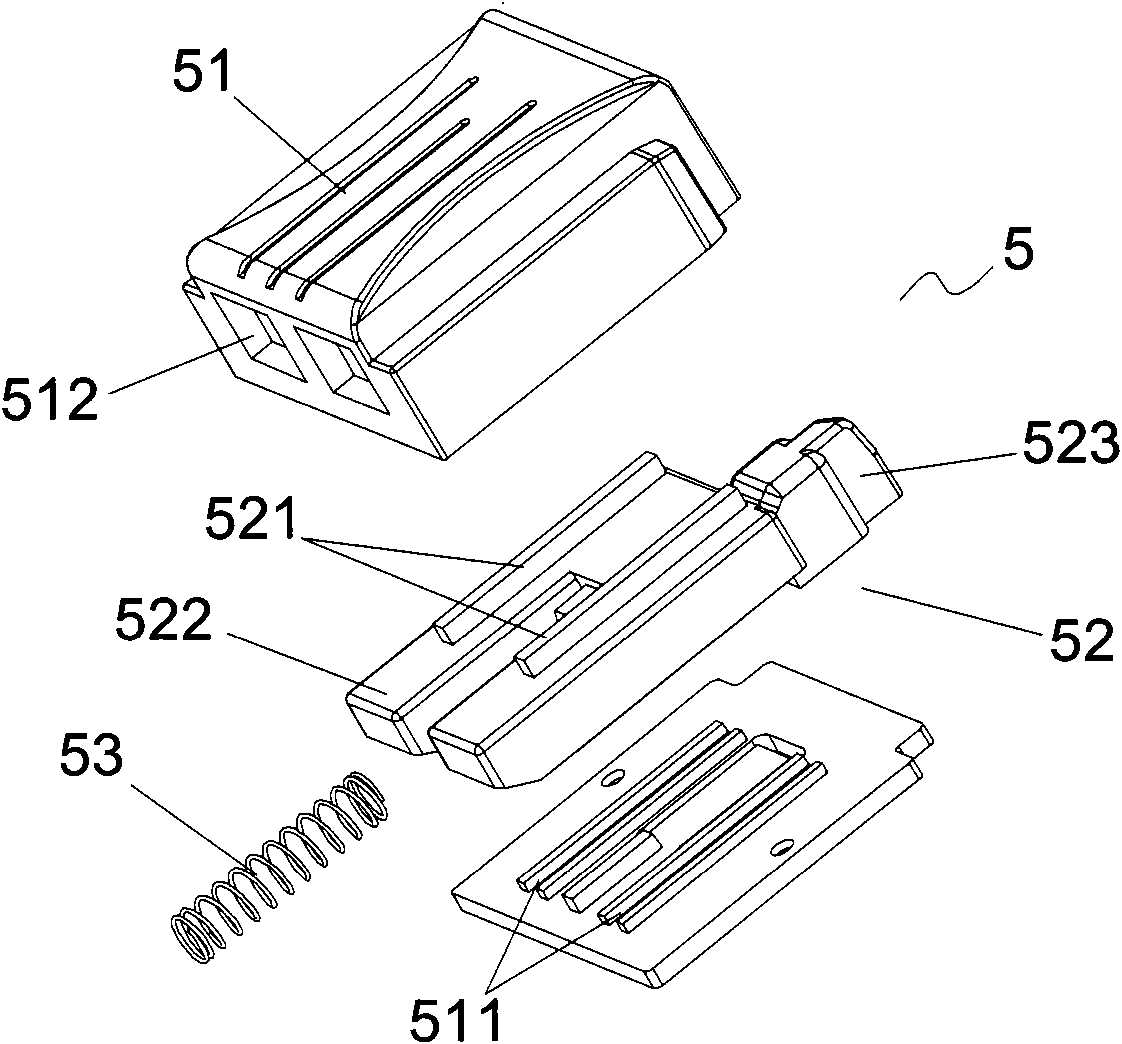

[0030] Such as Figure 7 As shown, the battery pack assembly of the electric vehicle of the present invention includes: three lithium batteries 1, a lead-acid battery, a battery management circuit, and a battery box 8 that can accommodate the lithium battery 1 and can be fixed on the frame of the electric vehicle. Battery wells for lead-acid batteries. The battery box 8 and the battery slot can be respectively arranged in appropriate positions according to the shape design of the electric vehicle, such as under the seat cushion, the chassis and the like.

[0031] Such as Figure 6 As shown, the top opening of the battery box 8 is divided into three battery installation compartments 82 by a partition 86, and the three lithium batteries 1 are respectively inserted downward into the three compartments of the battery box 8 from the top opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com