Stitch cam of computerized flat knitter

A computerized flat knitting machine and delta mesh technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of path deviation and no protective measures on the first slope, and achieve the effect of avoiding path deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

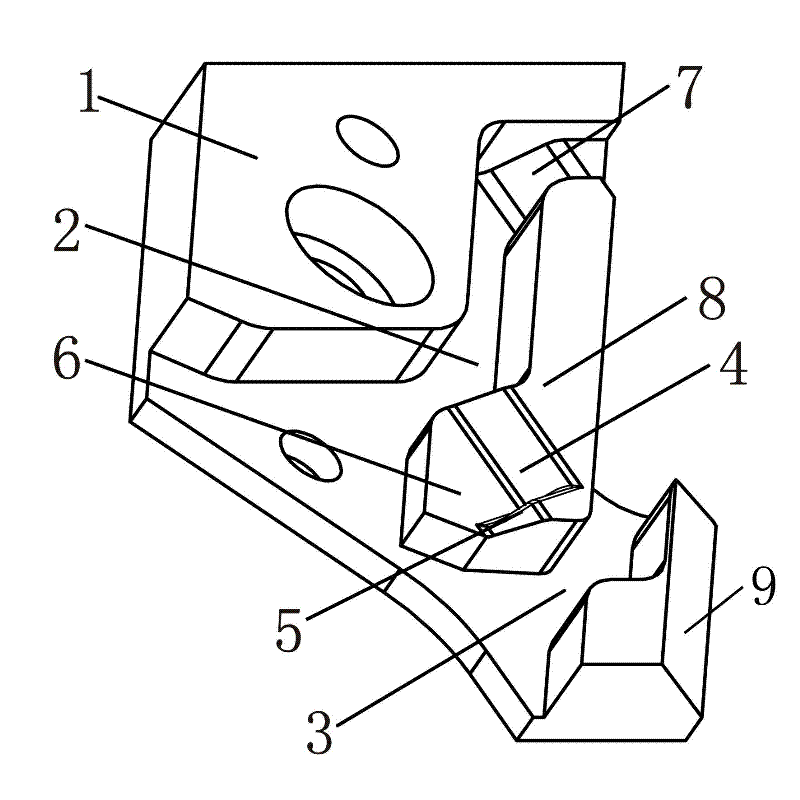

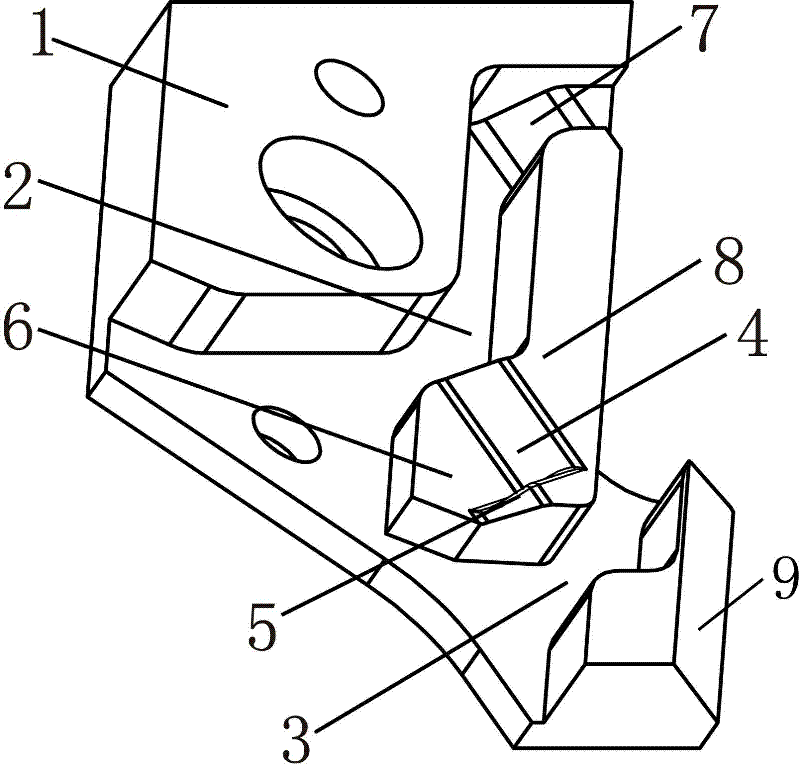

[0015] See attached picture. The main body 1 of this embodiment is a trapezoidal plane, and there is an additional block outside the base of the first acute angle of the trapezoid, which is integrated with the main body 1; a second acute angle extends from the first obtuse angle of the trapezoid to the second acute angle. A groove 2, the second opening of the first groove 2 at the first obtuse angle is trumpet-shaped; a second groove 3 extends from the middle of the first side to between the additional block and the main body 1, the second groove 3 The opening of the third groove in the middle of the first side is also trumpet-shaped. The first groove 2 and the second groove 3 meet at the first side, forming a first slope 4 and a first plane 6 higher than the first and second grooves at the angled part thereof; the first slope 5 is inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com