Test bed for detecting positive and negative work of linear moving electric mechanism

An electric mechanism and linear detection technology, which is applied in the field of test benches, can solve the problems of labor and time-consuming, inconvenient operation of the life test bench, and inability to test the life test of the linear motion electric mechanism, and achieves simple and compact structure, simple and reliable design processing, The effect of simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

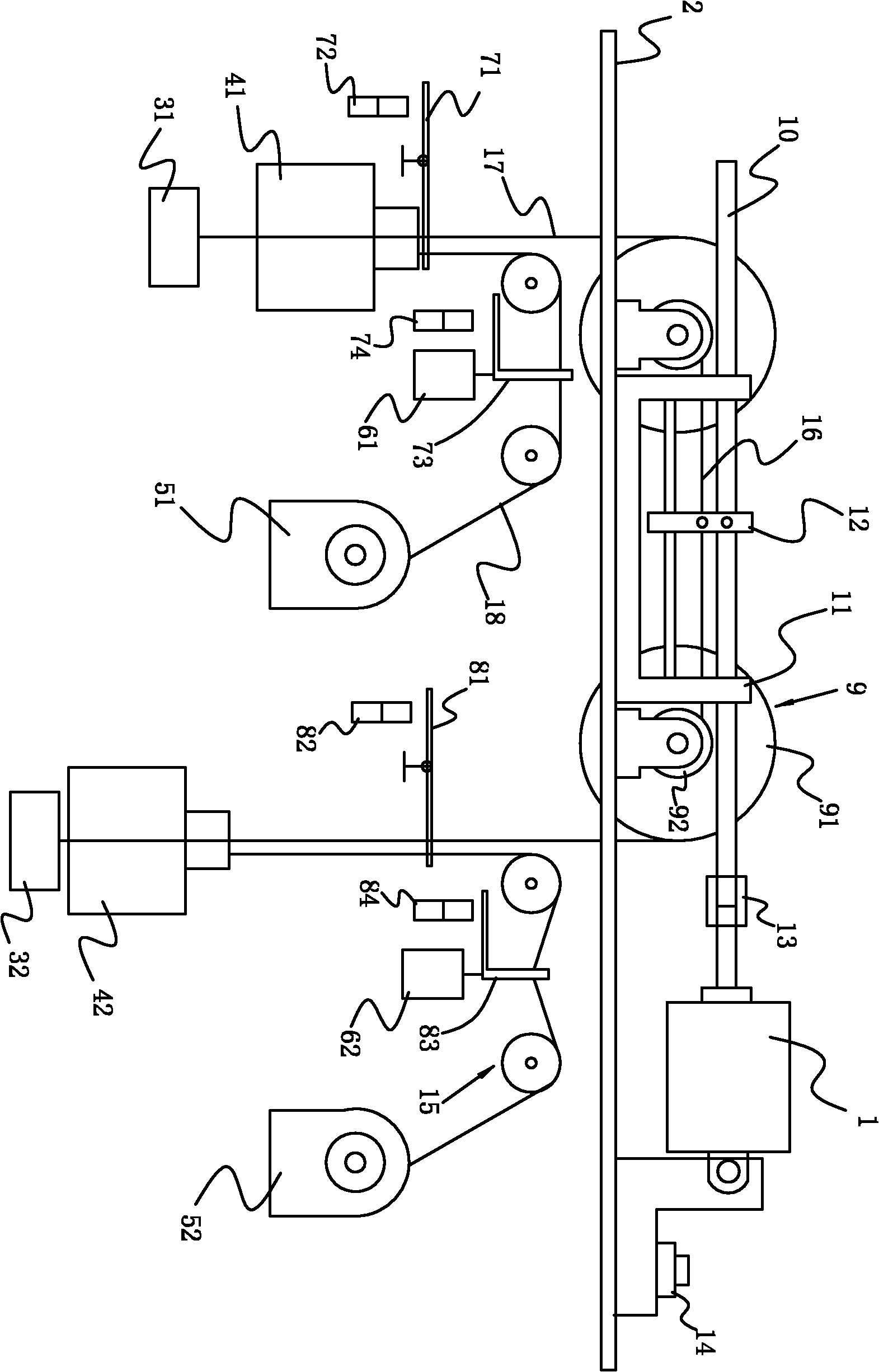

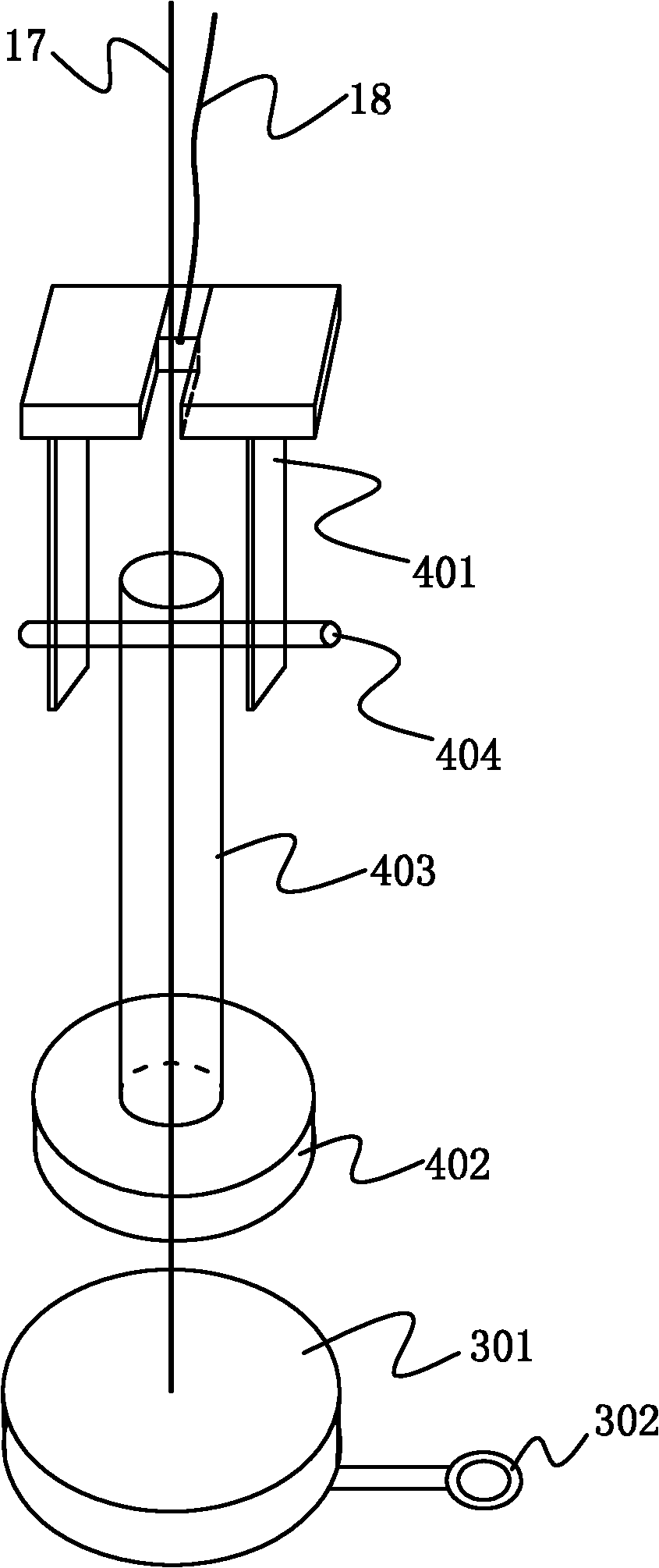

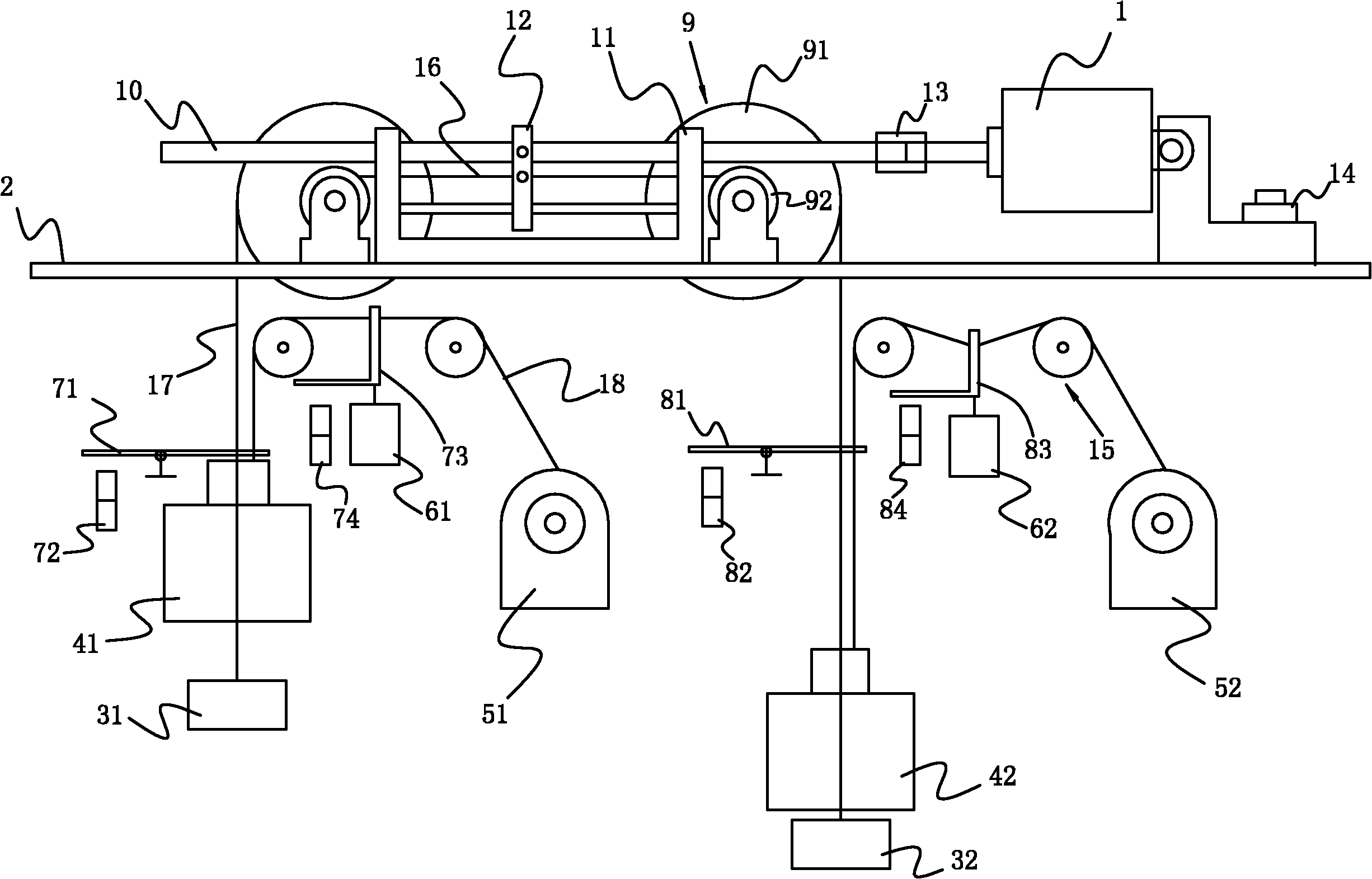

[0030] 1. Linear sliding rod assembly:

[0031] Convert linear motion to rotary motion. A vertically downward rectangular iron block (link block) is fixedly installed in the middle of the sliding bar. A hole is punched in the middle of the iron block, and a loading wire rope is fixed in the left and right directions to pull the left and right loading wheels. A thin iron rod used to limit the rotation of the iron block. When the product pushes the sliding rod to move to the left, the long iron block installed in the middle of the sliding rod will also move to the left, and the steel wire rope fixed on the right side of the iron block pulls the loading wheel on the right and drives the load changing wheel on the same axis to rotate counterclockwise. The hanging wire rope fixed on the load changing wheel pulls up the mound on the right. The loading wire rope on the left side of the iron block is slack at this time, but because the counterweight bottom mound is hung on the load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com