Motor shell

A motor shell and peripheral technology, which is applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem that the installation method of the load-fixed mounting frame cannot be satisfied, and the impact on the manufacturing and use of plastic-sealed motors, installation distance and installation Difficult to adjust the position and other problems, to achieve the effect of convenient and reliable assembly and disassembly, compact structure and low structural cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

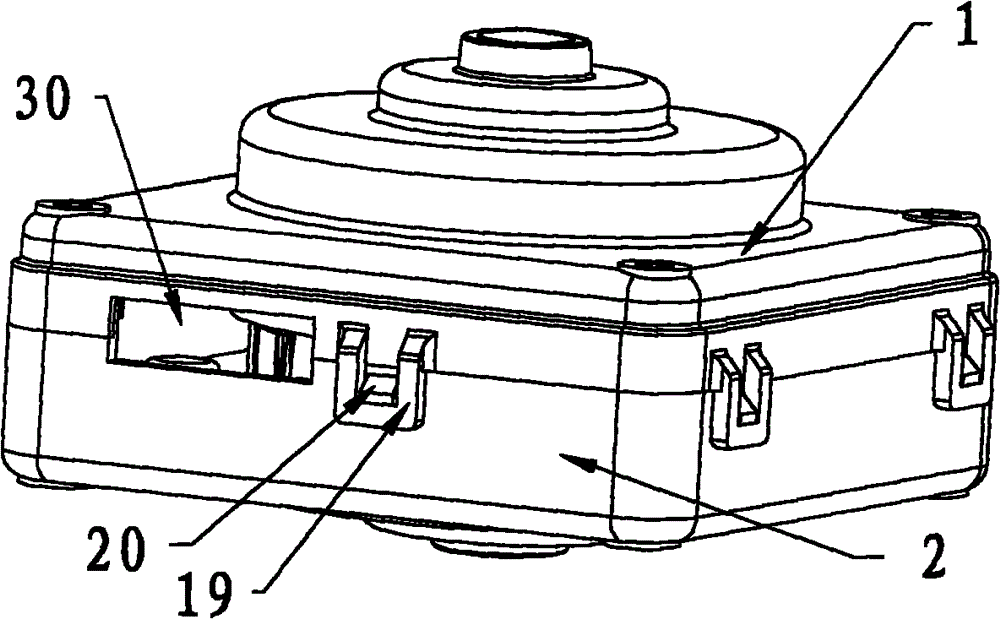

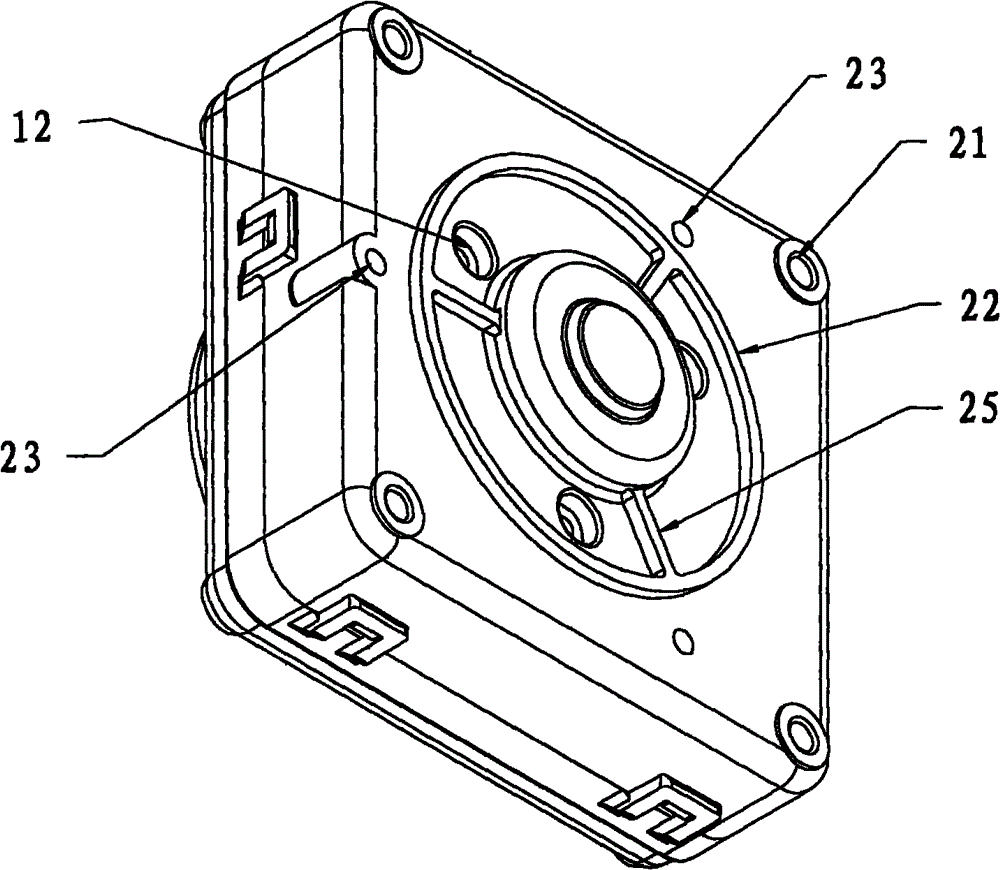

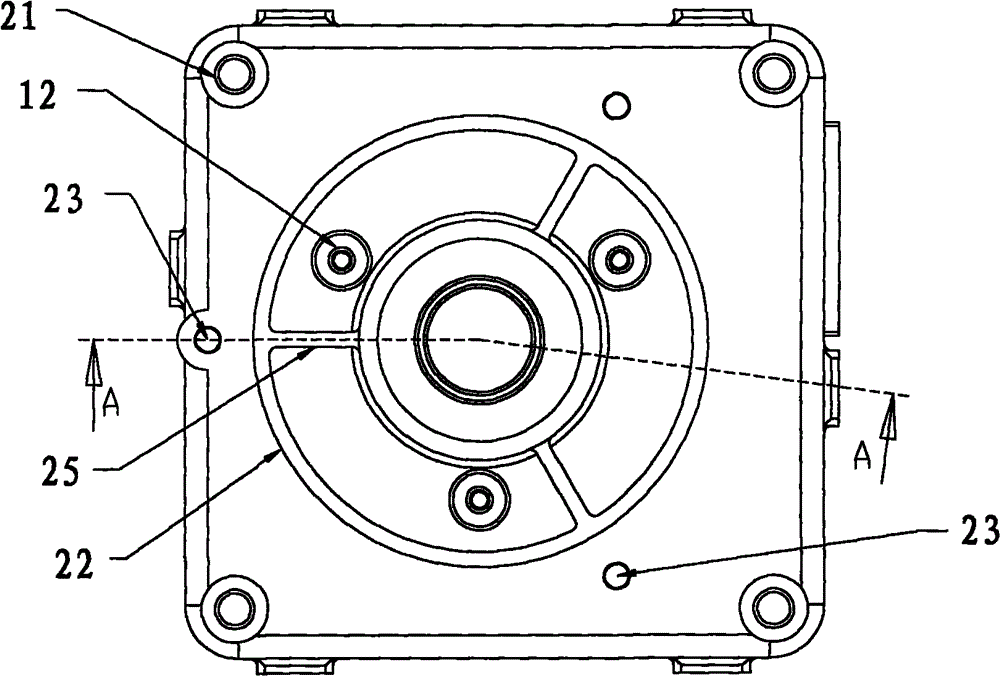

[0025] Such as Figure 1 to Figure 9 As shown, a motor casing includes a front end cover 1 and a rear end cover 2. The front end cover 1 and the rear end cover 2 are installed together to form a plurality of cavities, wherein the top of the front end cover 1 is provided with a first bearing cavity 3, and the first A stator containment cavity 4 is provided below the bearing cavity 3, a circuit board containment cavity 5 is formed below the stator containment cavity 4 and inside the rear end cover 2, and a second bearing cavity is formed below the circuit board containment cavity 5 and the bottom of the rear end cover 2 6.

[0026] Wherein the front end cover 1 and the rear end cover 2 are made of plastics, the area of the circuit board containing cavity 5 is larger than the area of the stator containing cavity 4, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com