Apparatus and method for continuous wort boiling

A wort and guiding device technology, which is applied in the preparation of wort, biochemical equipment and methods, and brewing of beer, and can solve the problems of high equipment investment costs and construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

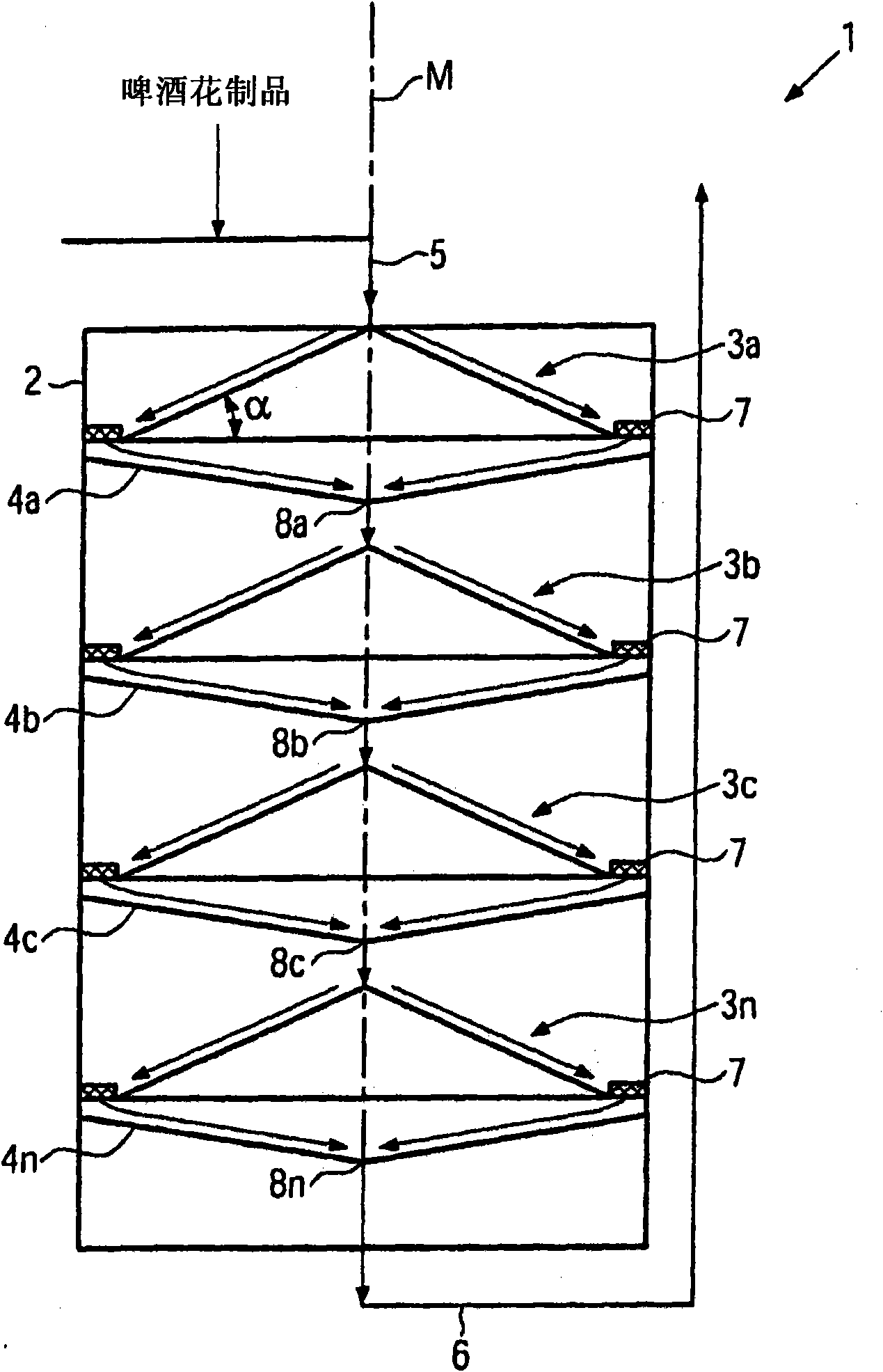

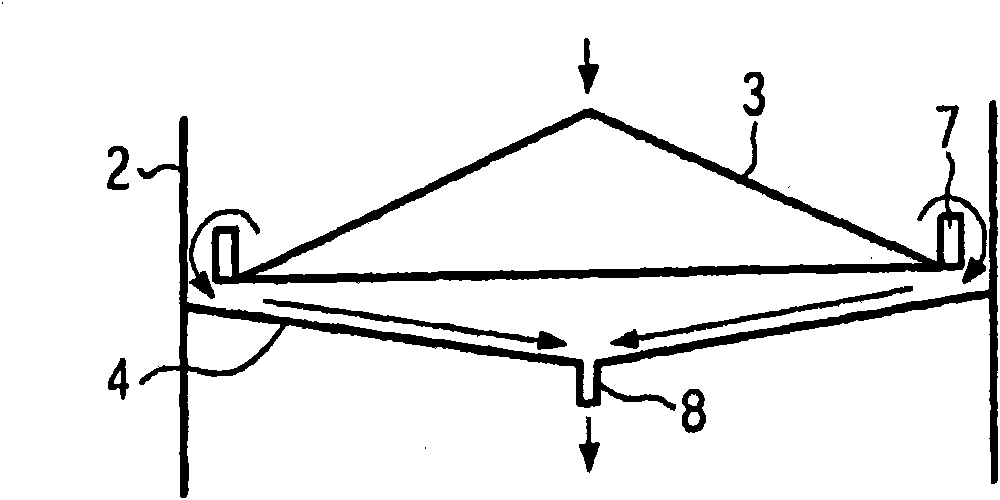

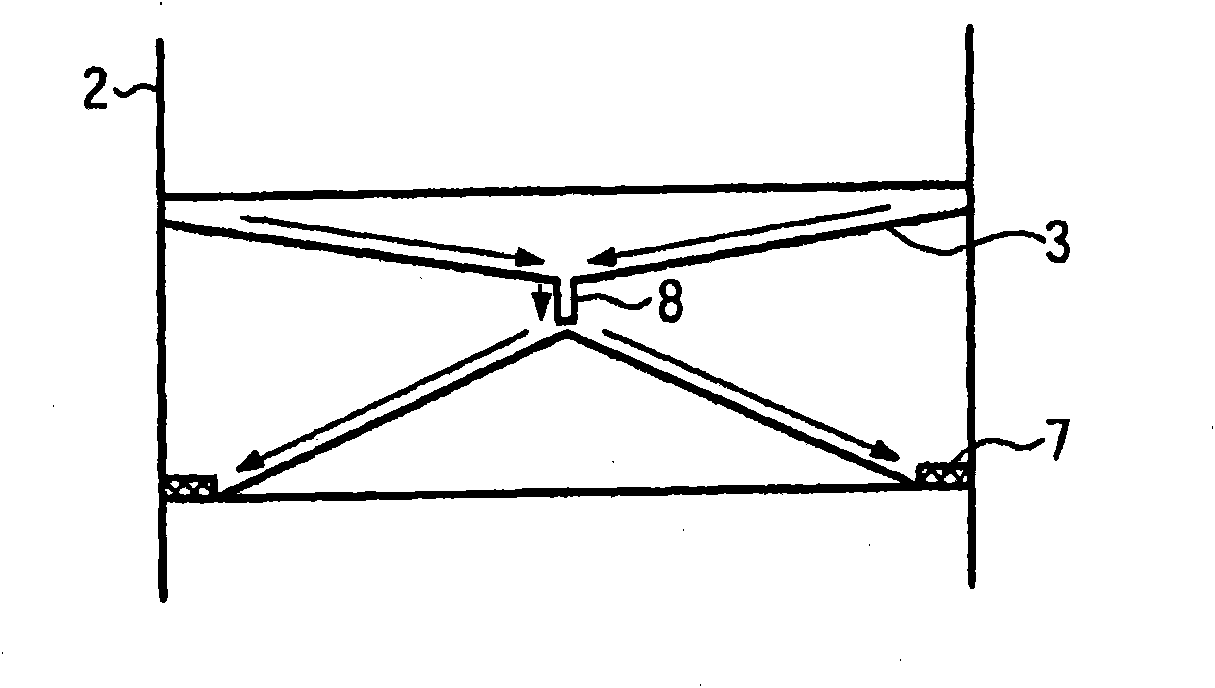

[0027] figure 1 A cross-sectional view of a device for boiling wort according to the invention is schematically shown. The device has an inlet 5 for the clarified wort, preferably into which isomerized hop preparations (eg extracts) and / or conventional hop preparations are fed. In the preferably hollow cylindrical housing 2 there are heating surfaces 3 a to 3 n arranged one above the other in the shape of a cascading waterfall. The heating surface is designed here as a conically extending conical surface, the tip of which points upwards. In order to heat the heating surface 3 , the heating surface can be designed as a double-walled umbrella, for example hot steam or a heat exchange medium or water or high-pressure hot water can be guided through the inner space of the umbrella. Furthermore, the heating surface has inlets and outlets (not shown) for the heat exchange medium. The different heating surfaces 3 a to 3 n arranged one above the other can be connected in a common t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com