Device for injecting a liquid load to be mixed/converted inside a plasma needle or a gaseous flow

A technology of plasma and equipment, applied in the field of liquid injection system, can solve the problems that cannot be satisfied at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

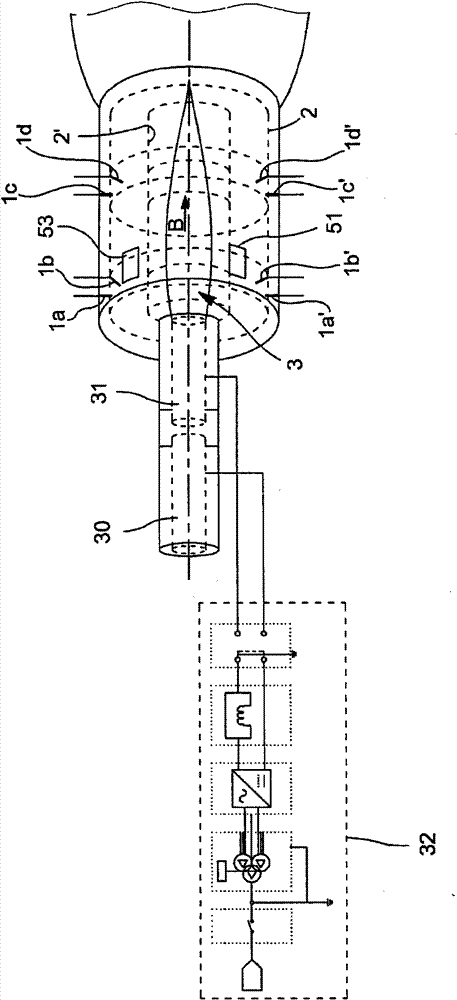

[0076] The following will combine Figure 1A The views shown illustrate one embodiment of the invention.

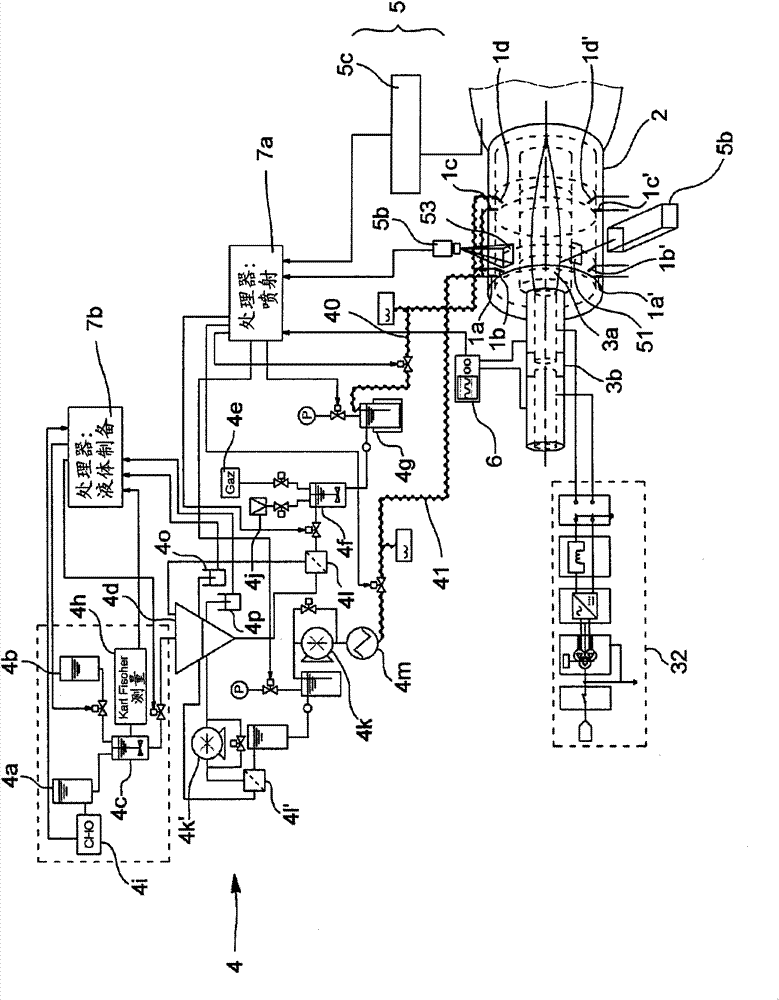

[0077] Figure 1B This device is included with additional peripherals that will be described further.

[0078] exist Figure 1A In the figure, reference numerals 30 and 31 denote electrodes, and discharges are generated between them. At the same time, the passage of the plasmaized gas through these electrodes leads to the formation of a plasma plume 3 .

[0079] The power supply for the electrodes is indicated by reference numeral 32 .

[0080] At the output end of the electrode there is provided a system forming a support 2 for positioning and holding the injector for spraying the liquid to be treated. In a cavity 2' arranged in the support, the plasma plume flows substantially along an axis B, referred to below as the plasma flow axis. In one example, the cavity 2' is substantially cylindrical in shape and the axis B is the cylindrical symmetry axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com