Technology for processing curled tea and pressure-type tea shaping machine

A shaping machine and tea processing technology, which is applied in tea processing before extraction, etc., can solve the problems of inability to form intensive production, restrict the development of tea industry, and high labor intensity, and achieve the goals of increasing life expectancy, low working intensity, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention relates to a curling tea processing technology, which is to put the green tea leaves into a shaping machine for tea shape shaping, and then bake the shaped tea leaves. The shaping machine is a pressure-type tea shaping machine, and the pressure-type tea shaping machine refers to a shaping machine that uses pressure to squeeze and shape the green tea located in the shaping cavity. The number of times that the pressure-type tea shaping machine squeezes the tea green in the shaping cavity is preferably 4-5 times. During the shaping, the tea green that has been squeezed each time is loosened and then squeezed again.

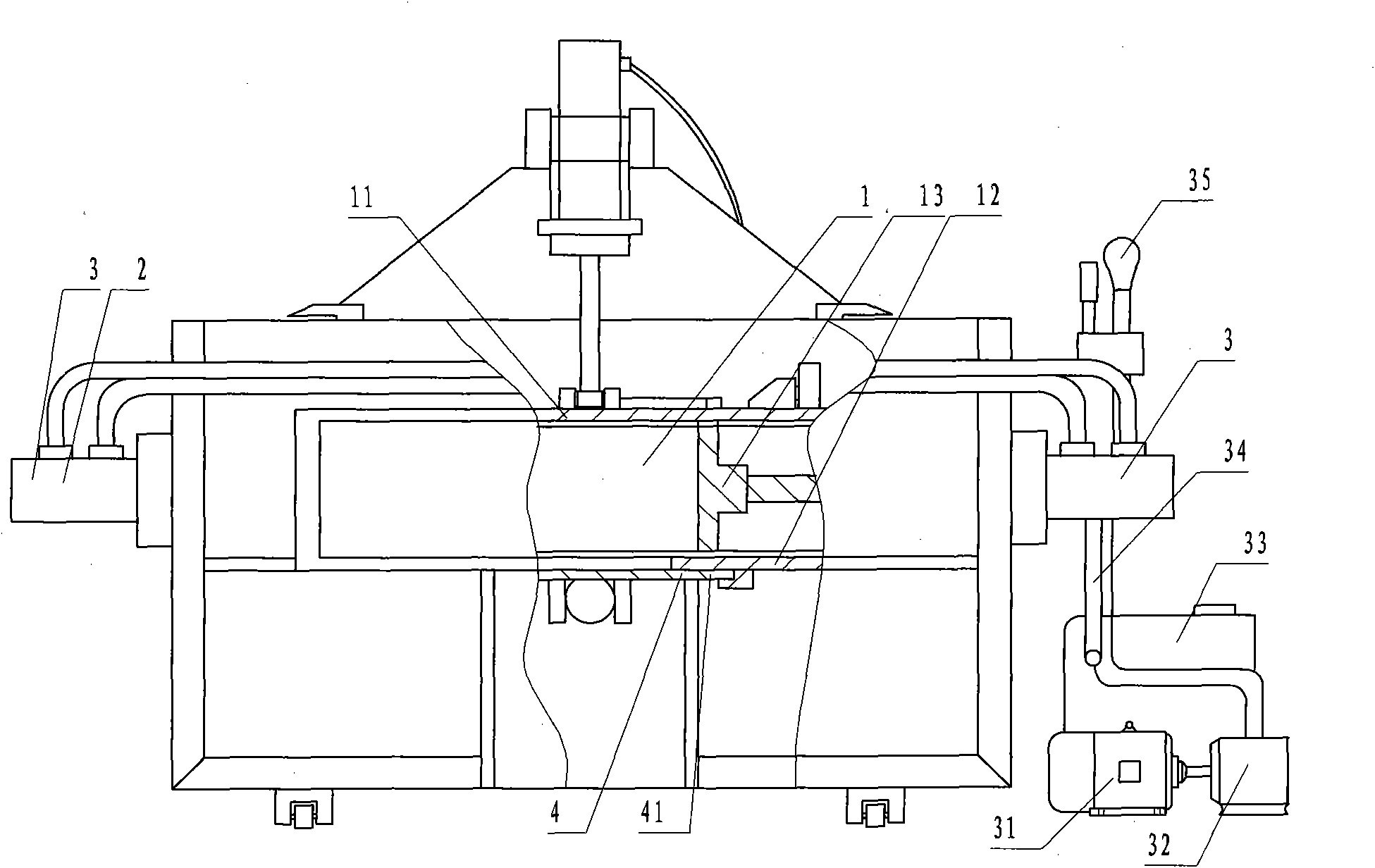

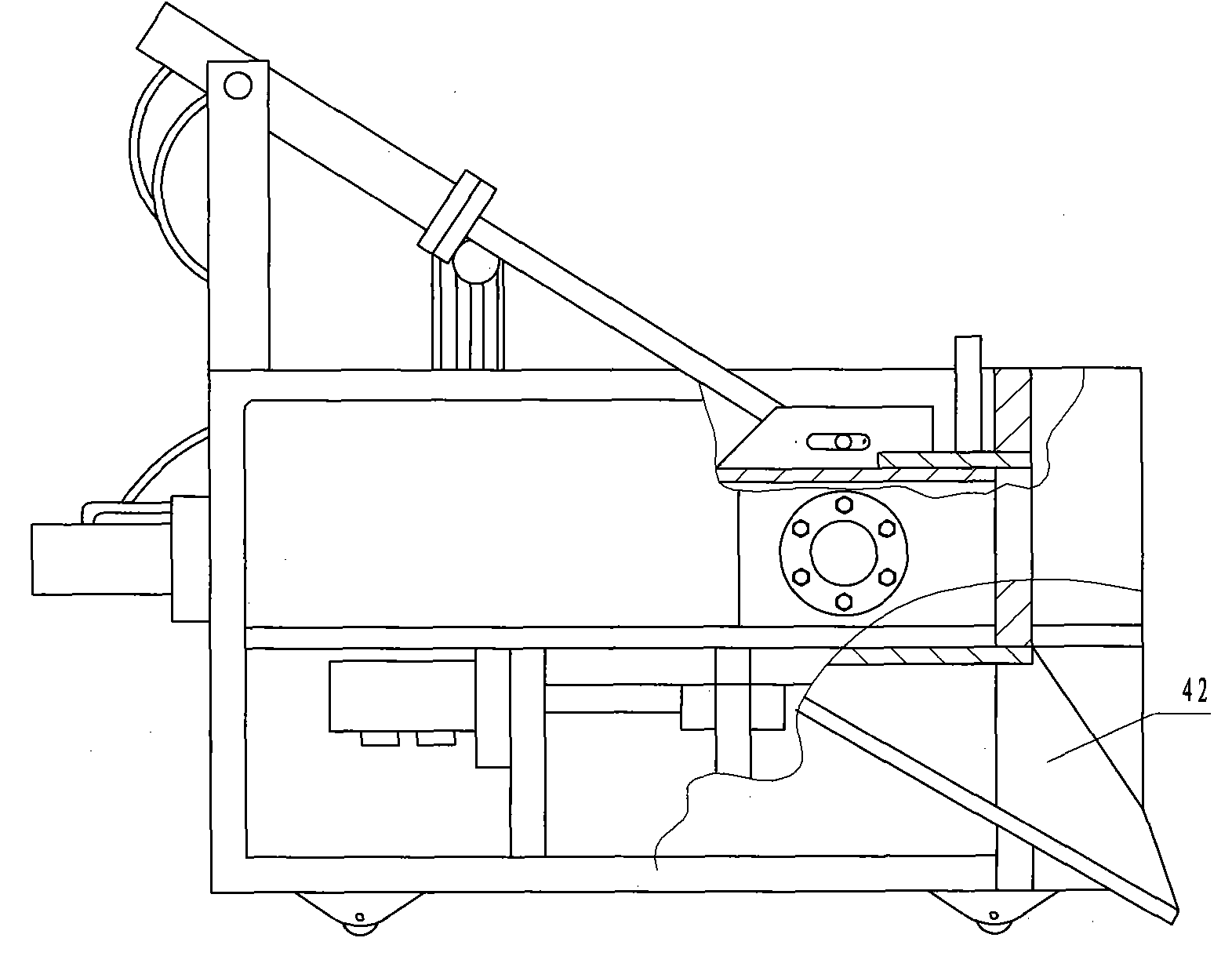

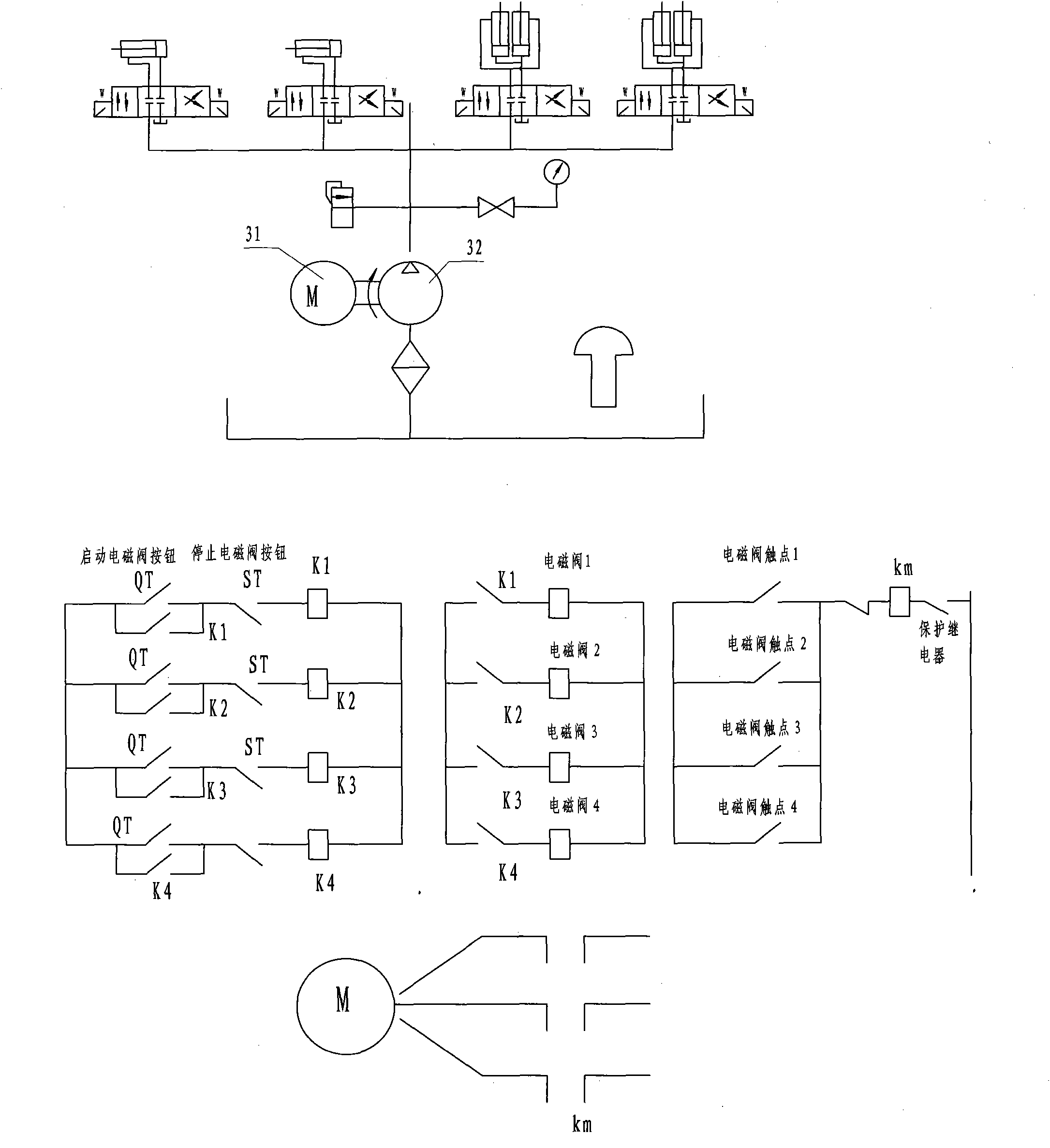

[0036] Pressure type tea shaping machine of the present invention such as Figure 1-3 As shown, it includes a plastic cavity 1 surrounded by a top cover, a bottom plate 12 and a side plate, and is used to push a power pusher 2 for pushing the top cover 11 and four-way side plates 13. The power pusher is a self-locking Oil cylinder 3 is formed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com