Method for processing automobile heat shield

A process method and technology of heat shields, which are applied to vehicle parts, movable outer sheaths, transportation and packaging, etc., can solve the problems of unstable processing process, long processing route, and difficult profile quality, etc., and achieve environmental protection Good effect, good molding effect, stable quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

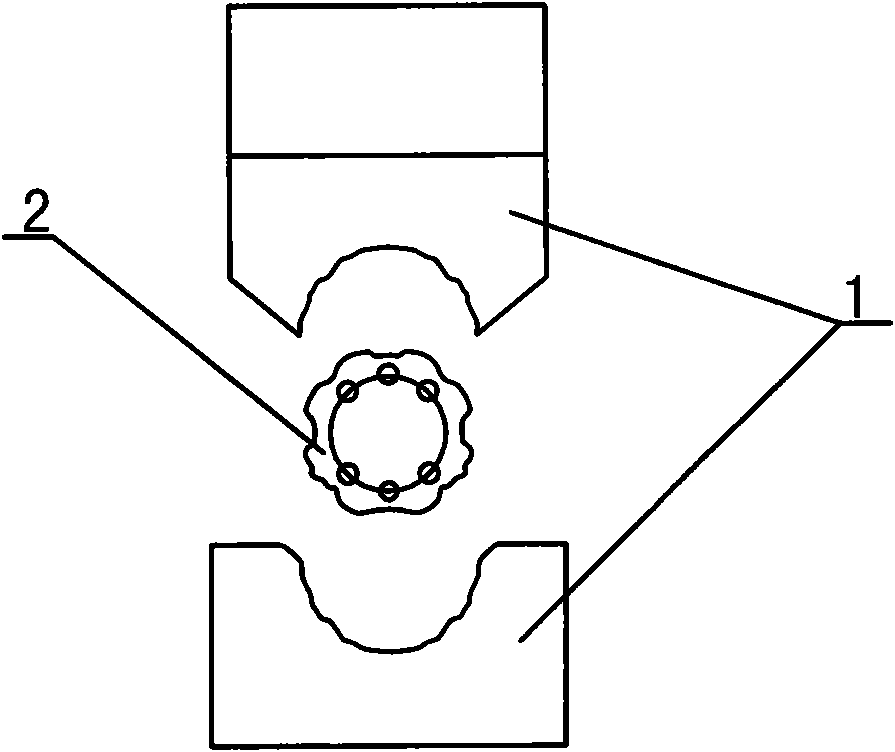

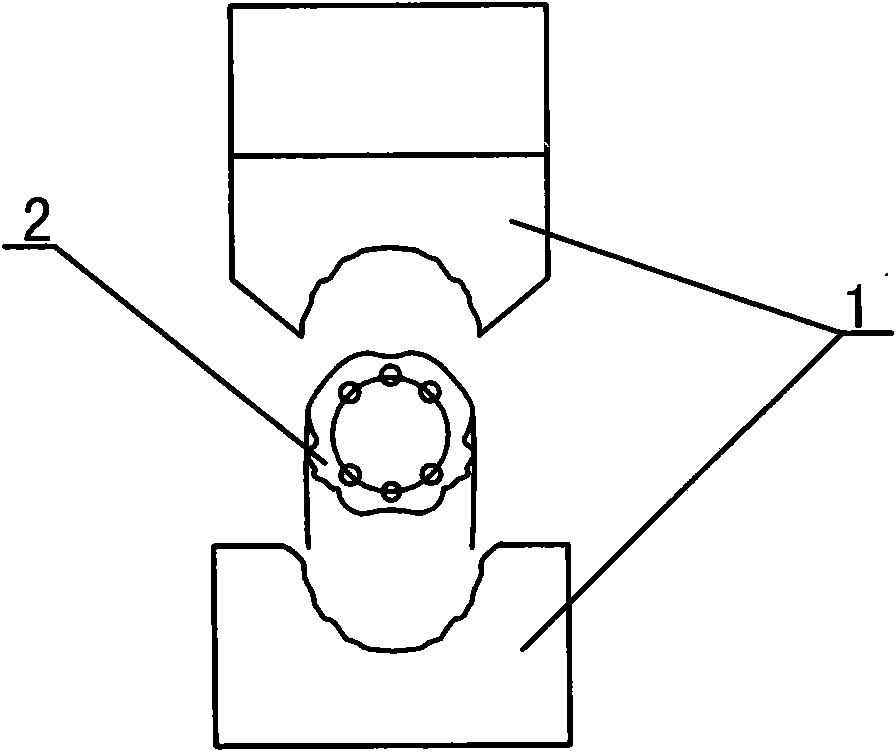

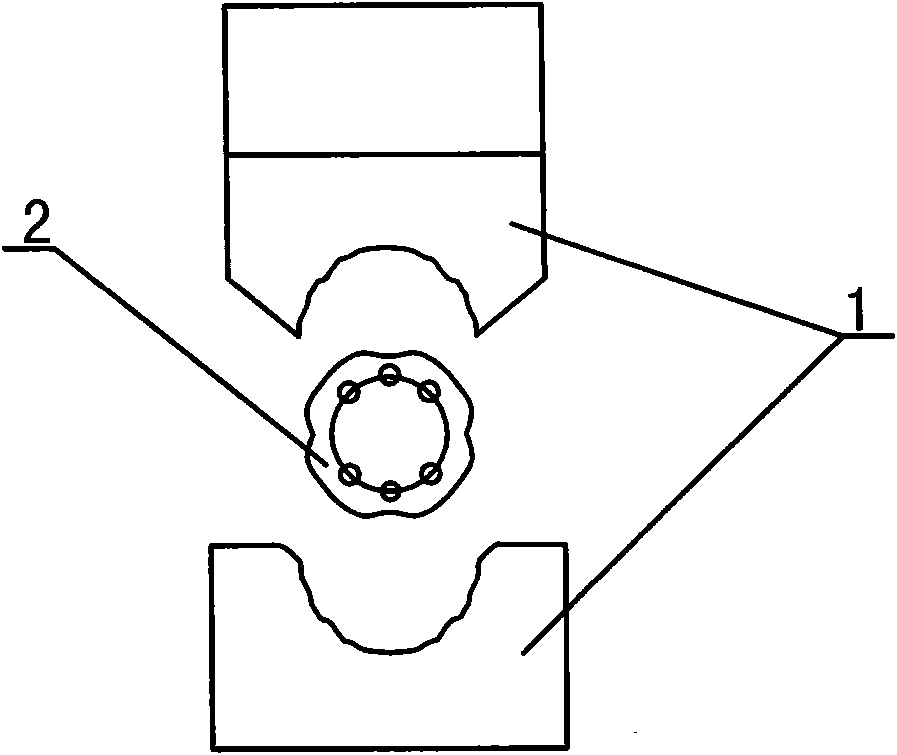

[0013] Such as Figure 1-3 As shown, the process method for processing a heat shield for automobiles according to the present invention includes the following steps:

[0014] (1) First, prepare and adjust the molding die equipment. The main processing units include the molding die 1, the core rod, the die, the feeding mechanism, the pressing mechanism and the punching mechanism. First, the metal ring 2 to be processed is placed in the molding In the working area of the processing and forming die 1 of the equipment;

[0015] (2) Put the metal ring part to be processed into the working area of the forming cavity of the forming equipment, and pass the metal ring part through the same pair of forming molds. First, the upper mold moves downward, and the plate is formed to a certain extent. After moving through the top cylinder, the upper mold continues to descend and contacts the lower mold, and the plate is bent into a circle in the lower mold cavity to realize the processing proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com