Switching mechanism of pneumatic nailing machine

A switch mechanism and trigger technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of pneumatic nailing machine batter and other problems, and achieve the effect of reducing processing cost, using safety, and improving the qualification rate of one-time installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

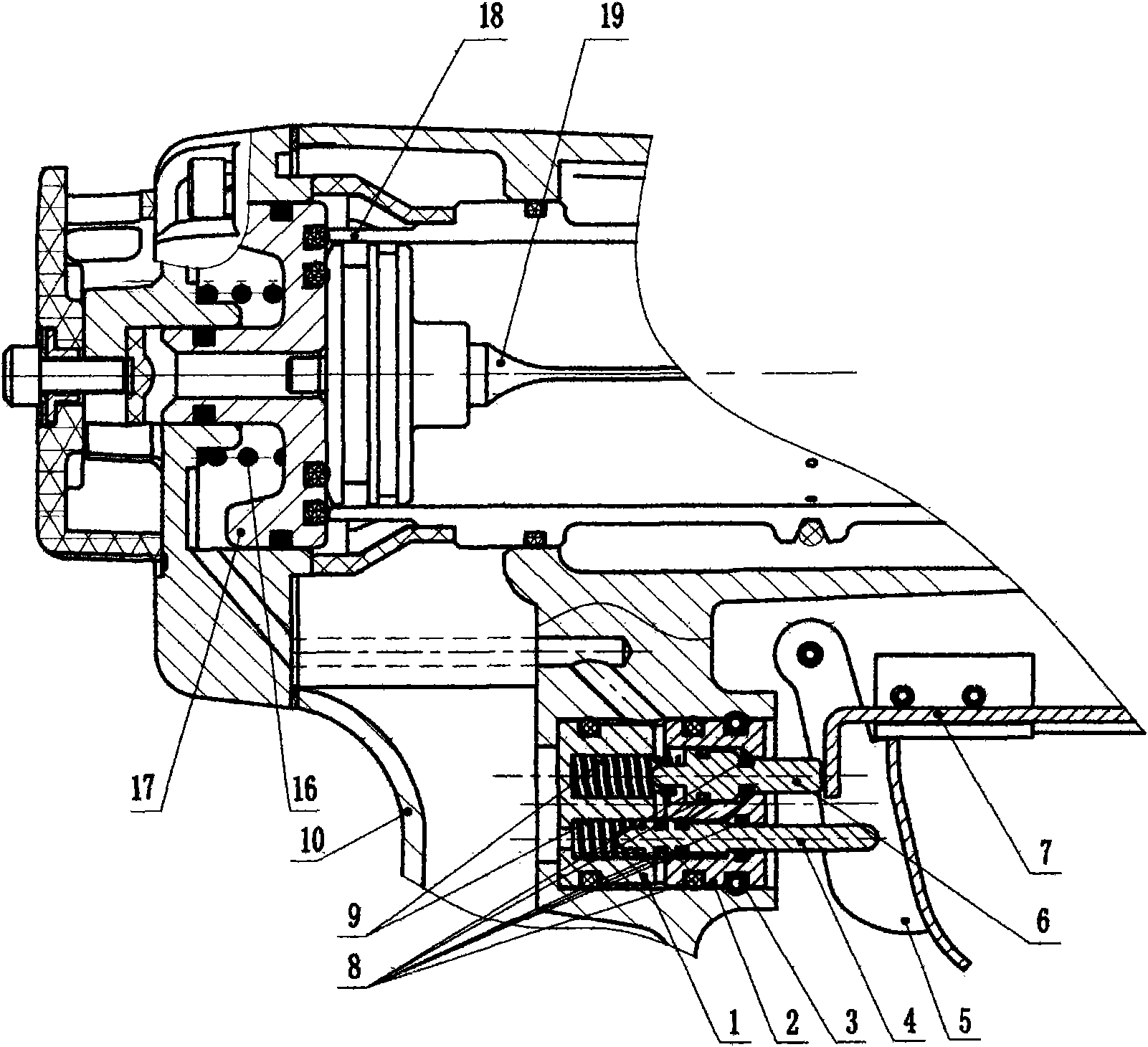

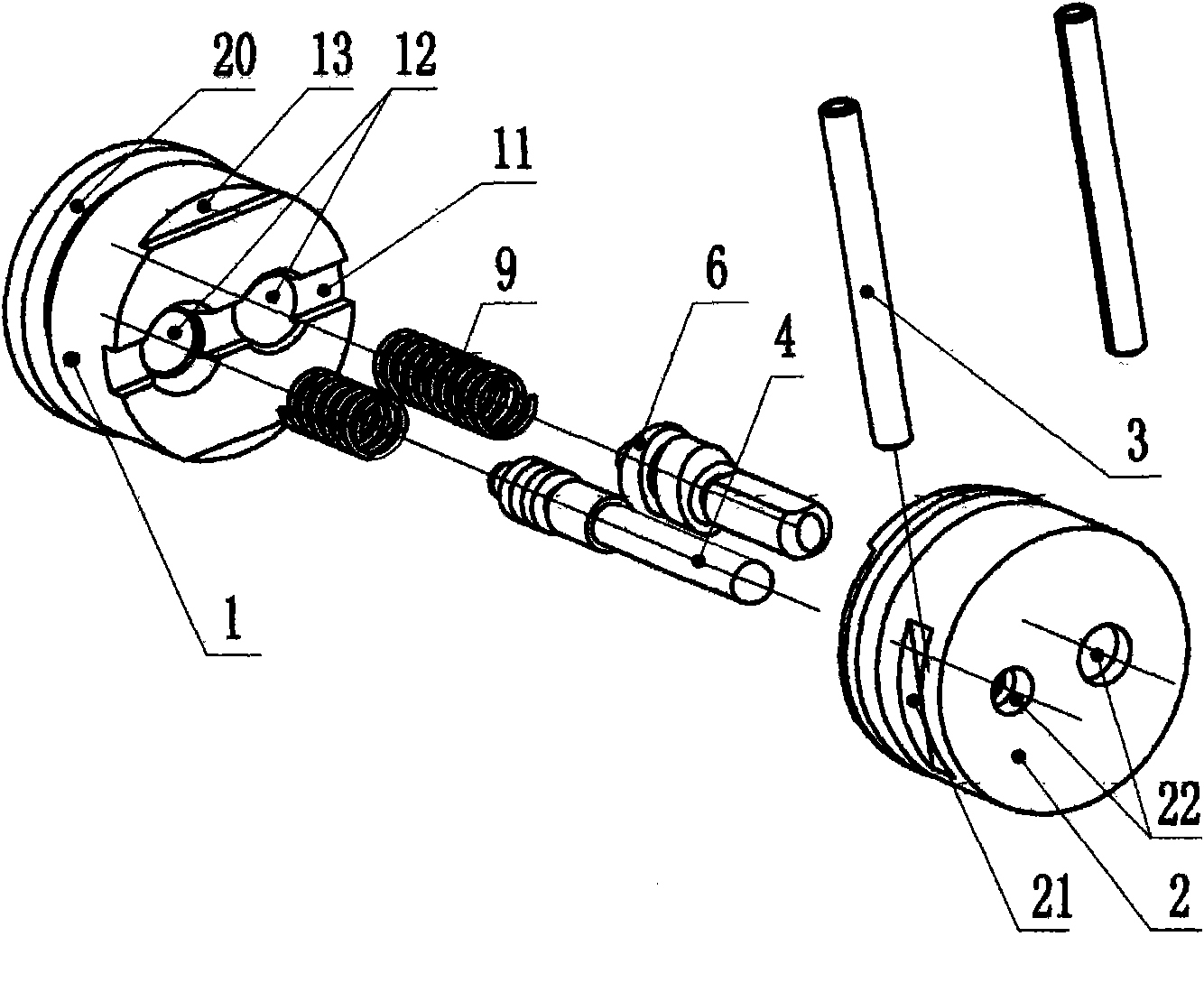

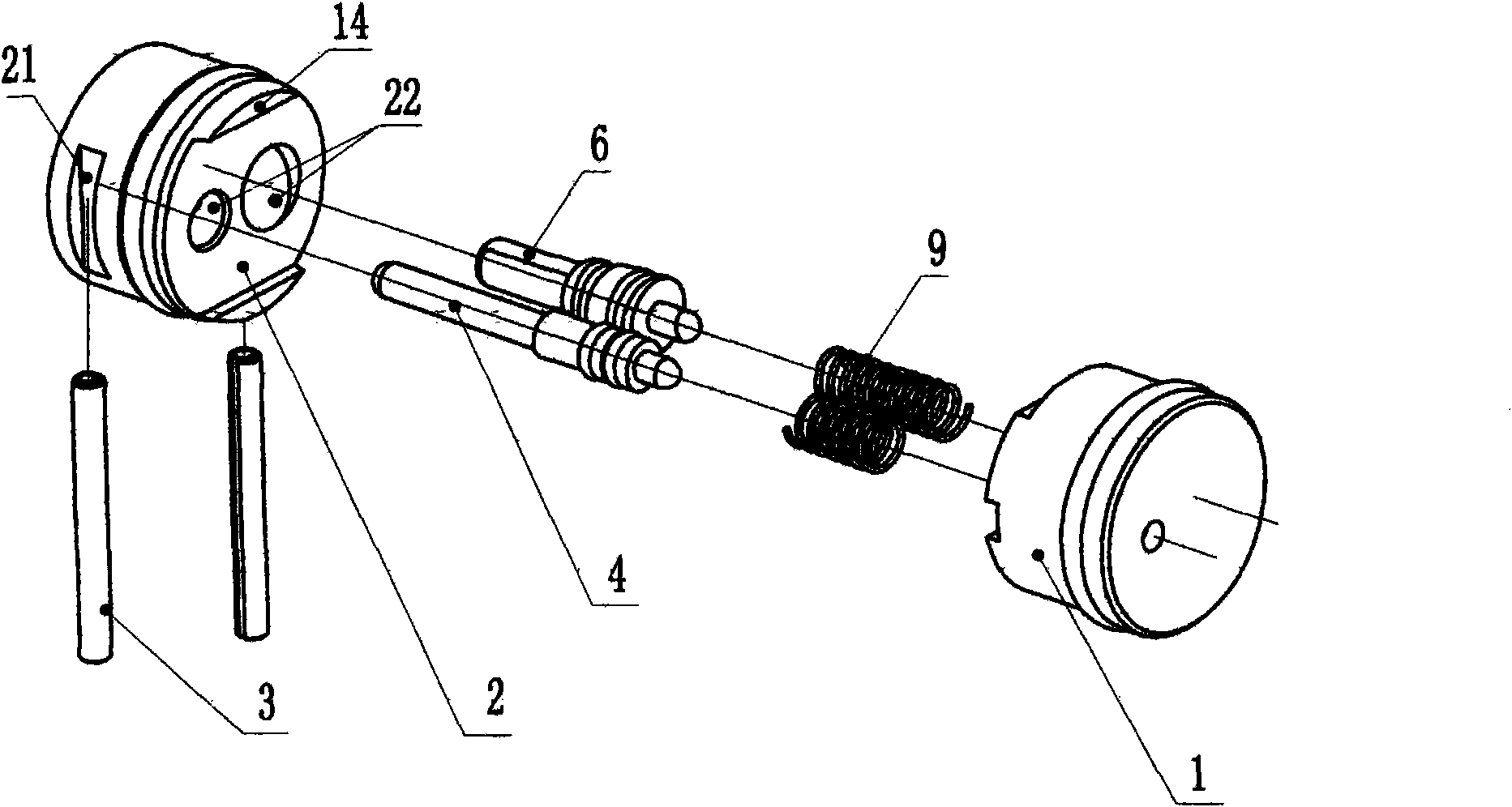

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is mainly composed of an upper air guide sleeve 1, a lower air guide sleeve 2, an elastic cylindrical pin 3, a trigger 5, a safety frame assembly 7, an "O" ring 8, and a valve stem compression spring 9; Roots are the lower valve stem 4 and the upper valve stem 6 respectively. The upper air guide sleeve 1 is provided with an outer ring groove 20 on its periphery, and an "O" ring 8 is installed on the outer ring groove for sealing with the housing 10. The middle groove 11 opened in the middle of the front side plays the role of air flow direction. Two holes 12 are also arranged in the middle to play a guiding and sealing role, and two sunken steps 13 cooperate with the lower air guide sleeve 2 . The lower air guide sleeve 2 plays the role of sealing and fixing the upper air guide sleeve 1. Two outer grooves 21, two bosses 14 and two holes 22 are arranged on both sides of the lower air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com