Paint for coating surface of sanitary ware made of composite materials and preparation method thereof

A sanitary ware and surface coating technology, applied in the direction of coating, etc., can solve the problem that the coating film has not been widely used, and achieve important economic and social benefits, high smoothness, and low surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 white high-gloss baking varnish coating

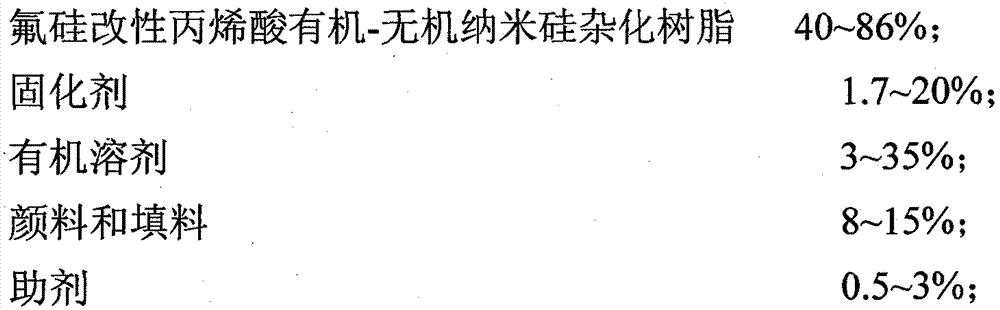

[0045] The parts by weight of each composition of coating are:

[0046]

[0047]

[0048] Except for the amino resin, the other raw materials are added within 30 minutes, and stirred at a high speed at 2000rpm for 30 minutes;

[0049] Then add the amino resin and continue stirring for 20 minutes to form the coating.

[0050] When in use, the coating obtained in Example 1 is sprayed on the coating film formed on the surface of the sanitary ware, and cured at 180°C for 40 minutes to obtain a high-gloss, wear-resistant, and stain-resistant fluorosilicone-modified acrylic organic-inorganic nanosilica Resin white baking lacquer coating.

[0051] See Table 1 for the performance data of the coating formed by the coating prepared by the method of Example 1.

Embodiment 2

[0052] The preparation of embodiment 2 colored matte baking varnish coatings

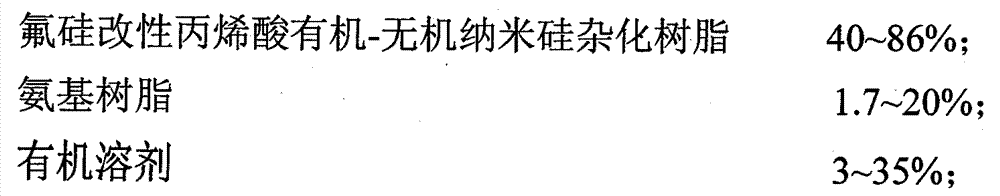

[0053] The parts by weight of each composition of coating are:

[0054]

[0055] Except for the amino resin, the other raw materials were added within 30 minutes, and stirred at a high speed at 2000rpm for 30 minutes; then the amino resin was added, and the stirring was continued for 20 minutes.

[0056] During use, the coating obtained in Example 2, when spraying, according to the ambient temperature and spraying requirements, add a certain amount of the above-mentioned organic solvent as a diluent to adjust the viscosity of the coating, and spray the coating film formed on the surface of the sanitary ware at 180 ° C. After curing for 40 minutes, a wear-resistant and stain-resistant fluorosilicone-modified acrylic organic-inorganic nano-silicon hybrid resin color matte baking varnish coating can be obtained; the level of gloss can control the amount of matte powder added.

[0057] See Table 1 f...

Embodiment 3

[0058] Embodiment 3 Two-component room temperature curing white coating (paint for repair)

[0059] The parts by weight of each composition of coating are:

[0060] A component:

[0061]

[0062] B component:

[0063] Curing agent (3390-BYK) (70% xylene solution) 15 parts

[0064] 3390-BYK: Hexamethylene polyisocyanate of aliphatic polyisocyanate

[0065] Organic solvents:

[0066] 15 parts of propylene glycol-butyl ether

[0067] Butyl acetate 5 parts

[0068] Propylene glycol-methyl ether acetate 30 parts

[0069] The ratio of the above-mentioned organic solvents can be adjusted according to the ambient temperature to facilitate the use in different seasons.

[0070] This embodiment 3 is a two-component package with external curing agent. When using it, add the hexamethylene polyisocyanate (3390) curing agent of BYK’s aliphatic polyisocyanate in proportion, and add a certain amount of diluent according to the viscosity of spraying , mechanical stirring for 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com