Paint for coating surface of sanitary ware made of composite materials and preparation method thereof

A sanitary ware and surface coating technology, applied in the direction of coating, etc., can solve the problem that the coating film has not been widely used, and achieve important economic and social benefits, low water absorption, and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

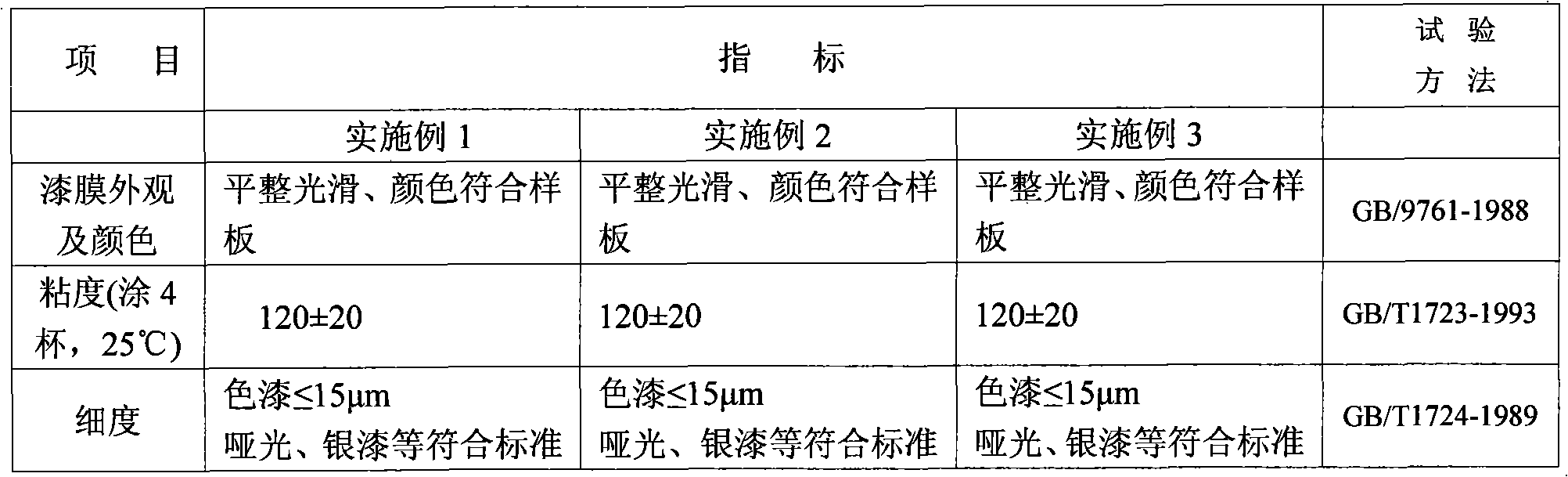

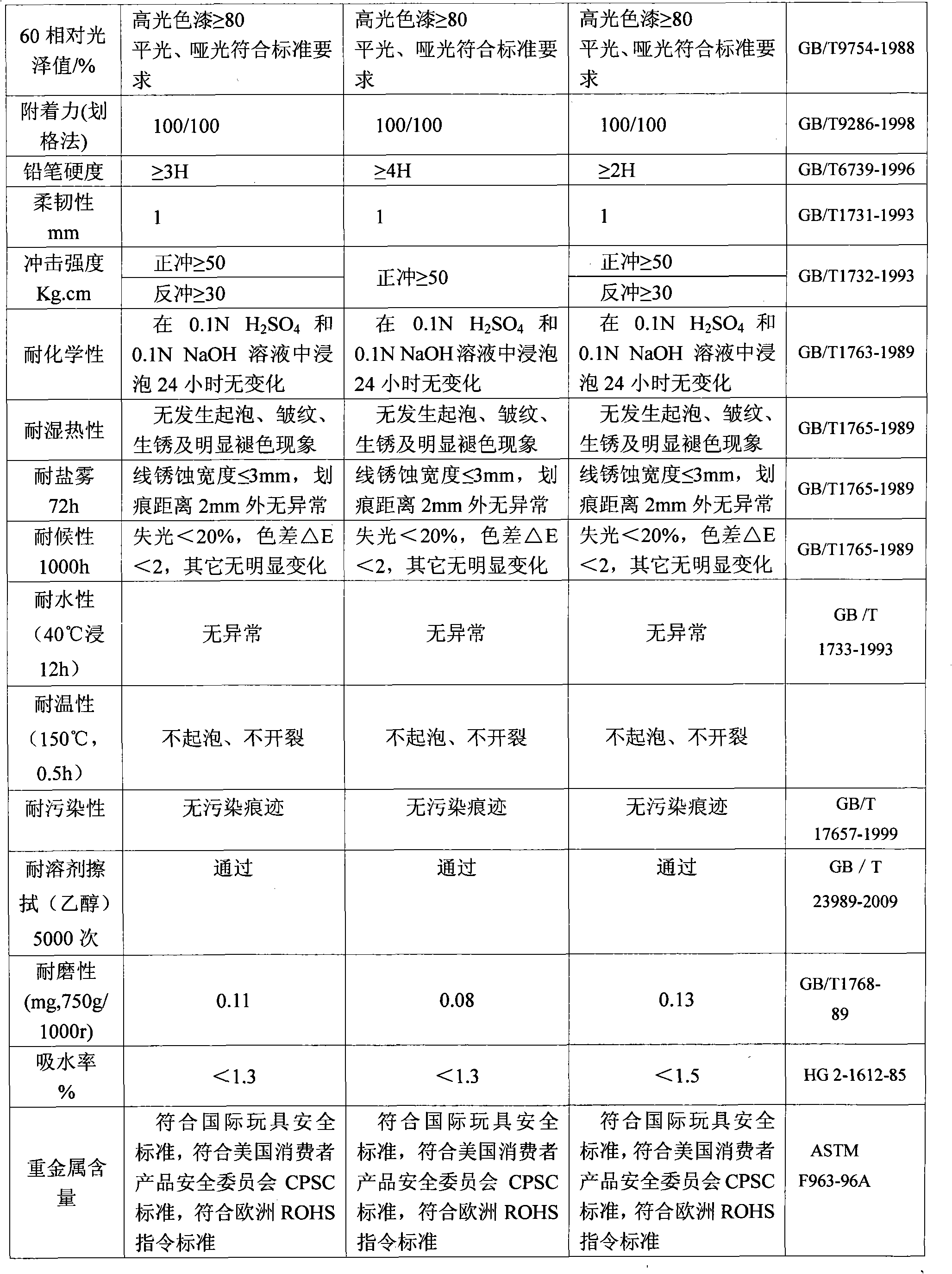

Examples

Embodiment 1

[0047] The preparation of embodiment 1 white high-gloss baking varnish coating

[0048] The parts by weight of each composition of coating are:

[0049] Fluoro-silicon modified acrylic / organic-inorganic nano-silicon hybrid resin 100 parts

[0050] Propylene glycol-butyl ether 25 parts

[0051] Butyl acetate 25 parts

[0052] 5 parts n-butanol

[0053] 2 parts p-toluenesulfonate ammonium salt solution

[0054] Titanium dioxide (rutile type) 25 parts

[0055] Dispersant (BYK-103) 0.1 parts

[0056] Defoamer (BYK-051) 0.2 parts

[0057] Leveling agent (BYK-300 and BYK-306) 0.5 part

[0058] Anti-settling agent (BYK-410) 0.3 parts

[0059] 11.25 parts of 303 amino resins (American Cytec Corporation)

[0060] Except for the amino resin, the other raw materials are added within 30 minutes, and stirred at a high speed at 2000rpm for 30 minutes;

[0061] Then add the amino resin and continue stirring for 20 minutes to form the coating.

[0062] When in use, the coating obta...

Embodiment 2

[0064] The preparation of embodiment 2 colored matte baking varnish coatings

[0065] The parts by weight of each composition of coating are:

[0066] Fluorosilicone modified acrylic acid / organic-inorganic nano silicon hybrid resin 84 parts

[0067] Propylene glycol-methyl ether acetate 1 part

[0068] 3 parts xylene

[0069] 3 parts of paint

[0070] Filling 6 parts

[0071] Matte powder (fumed silica) 3 parts

[0072] Dispersant (BYK-110, BYK-180) 0.3 parts

[0073] Defoamer (BYK-088) 0.4 parts

[0074] Leveling agent (BYK-310) 0.5 parts

[0075] Anti-settling agent (BYK 430) 0.5 parts

[0076] Amino resin 8.5 parts

[0077] Except for the amino resin, the other raw materials were added within 30 minutes, and stirred at a high speed at 2000rpm for 30 minutes; then the amino resin was added, and the stirring was continued for 20 minutes.

[0078] During use, the coating obtained in Example 2, when spraying, according to the ambient temperature and spraying requireme...

Embodiment 3

[0080] Embodiment 3 Two-component room temperature curing white coating (paint for repair)

[0081] The parts by weight of each composition of coating are:

[0082] A component:

[0083] Fluorosilicone modified acrylic acid / organic-inorganic nano silicon hybrid resin 86 parts

[0084] Titanium dioxide (rutile type) 14 parts

[0085] Dispersant (BYK-110) 0.4 parts

[0086] Defoamer (BYK-065) 0.4 parts

[0087] Leveling agent (BYK-323, BYK-331) 0.5 parts

[0088] Anti-settling agent (BYK 410) 0.5 parts

[0089] B component:

[0090] Curing agent (3390-BYK) (70% xylene solution) 15 parts

[0091] 3390-BYK: Hexamethylene polyisocyanate of aliphatic polyisocyanate

[0092] Organic solvents:

[0093] 15 parts of propylene glycol-butyl ether

[0094] Butyl acetate 5 parts

[0095] Propylene glycol-methyl ether acetate 30 parts

[0096] The ratio of the above-mentioned organic solvents can be adjusted according to the ambient temperature to facilitate the use in different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com