A special sealant for quantum dot packaging and preparation method thereof

A quantum dot and sealant technology, which is applied in the field of special sealant for quantum dot packaging and its preparation, to achieve the effects of fast curing speed, strong adhesion, and excellent light aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

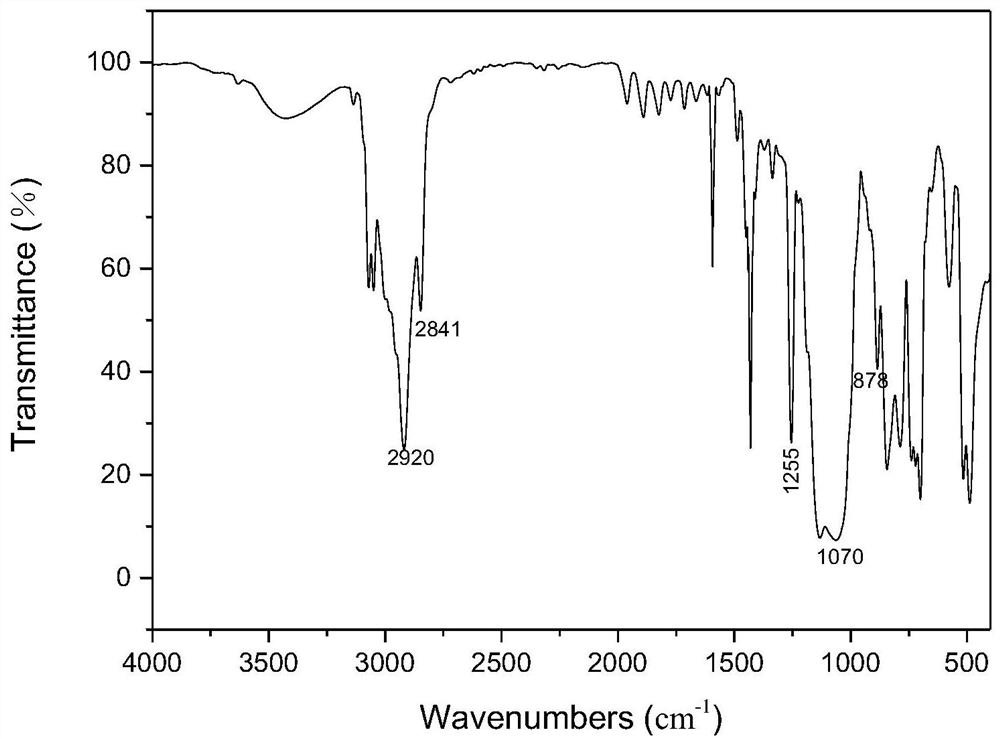

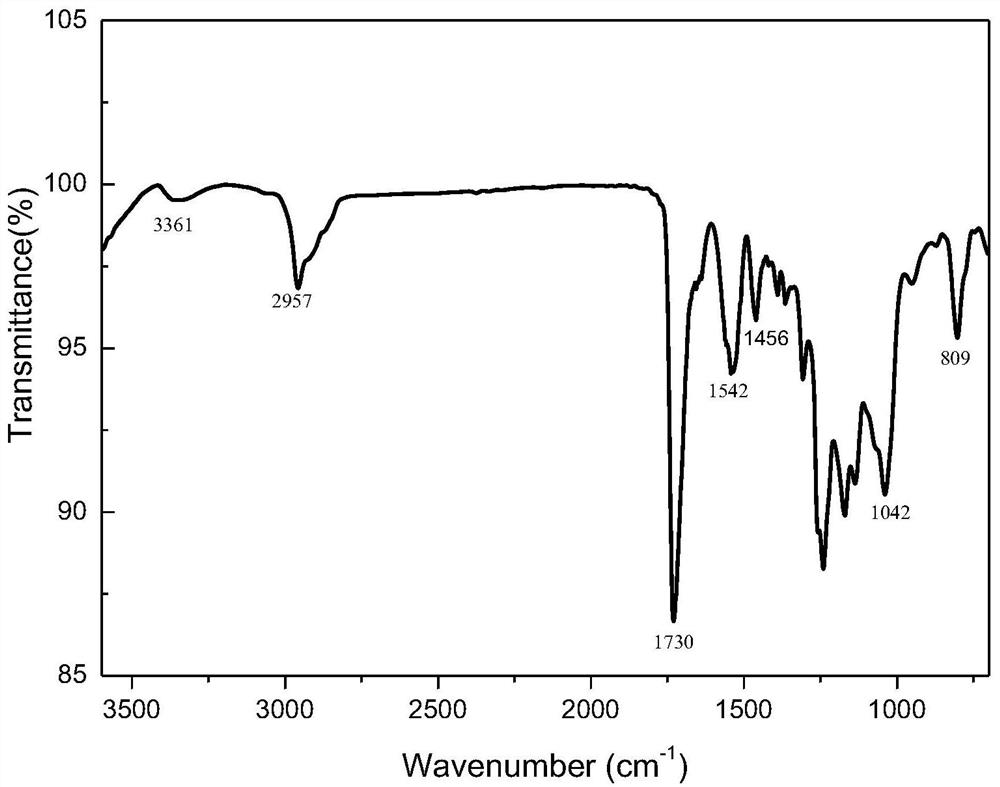

Method used

Image

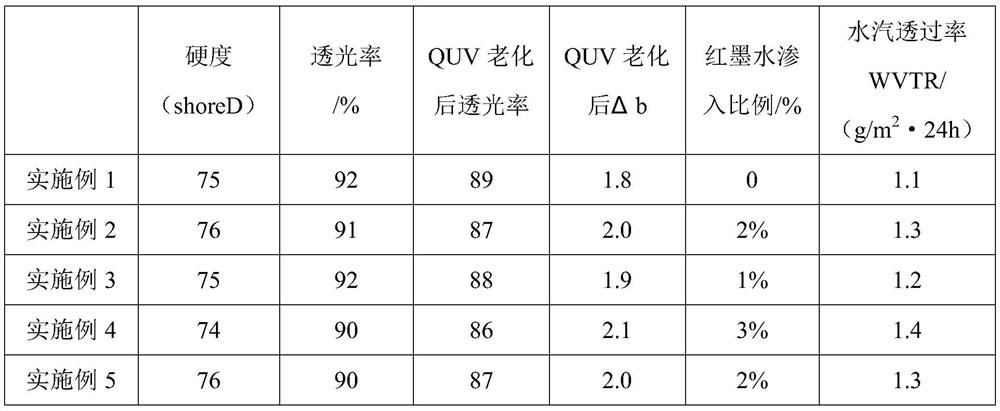

Examples

Embodiment 1

[0041] A special sealant for quantum dot packaging, which includes the following components calculated in parts by weight:

[0042] (1) Component A:

[0043] 70 parts of organosilicon modified epoxy resin;

[0044] 15 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate;

[0045] 15 parts of poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)-1,3-propanediol ether;

[0046] 4 copies of UVI 6976;

[0047] ITX 0.5 copies

[0048] (2) Component B:

[0049] 70 parts of polyurethane modified silicone resin;

[0050] 30 parts of dicyclopentadiene acrylate;

[0051] Darocur 1173 4 parts;

[0052] Wherein, the mass ratio of the A component and the B component is 3:1.

[0053] The preparation method of the special sealant for encapsulation of quantum dots described in this embodiment is as follows: component A and component B are uniformly mixed according to the mass ratio of 3:1 to obtain the special sealant for encapsulation of quantum dots.

Embodiment 2

[0055] A special sealant for quantum dot packaging, which includes the following components calculated in parts by weight:

[0056] (1) Component A:

[0057] 80 parts of organosilicon modified epoxy resin;

[0058] 20 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate;

[0059] 4 copies of UVI 6976;

[0060] ITX 0.5 copies

[0061] (2) Component B:

[0062] 70 parts of polyurethane modified silicone resin;

[0063] 30 parts of dicyclopentadiene acrylate;

[0064] Darocur 1173 4 parts;

[0065] Wherein, the mass ratio of the A component and the B component is 3:1.

[0066] The preparation method of the special sealant for encapsulating quantum dots is the same as that in Example 1, and will not be repeated here.

Embodiment 3

[0068] A special sealant for quantum dot packaging, which includes the following components calculated in parts by weight:

[0069] (1) Component A:

[0070] 70 parts of organosilicon modified epoxy resin;

[0071] 30 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate;

[0072] 4 copies of UVI 6976;

[0073] ITX 0.5 copies

[0074] (2) Component B:

[0075] 70 parts of polyurethane modified silicone resin;

[0076] 30 parts of dicyclopentadiene acrylate;

[0077] Darocur 1173 4 parts;

[0078] Wherein, the mass ratio of the A component and the B component is 3:1.

[0079] The preparation method of the special sealant for encapsulating quantum dots is the same as that in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com