Composite anti-explosion post of reinforced concrete with encased steel plate and construction method thereof

A reinforced concrete column and reinforced concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problem that it is difficult to ensure the joint action of the steel plate and the original concrete to transmit shear force, so as to achieve less construction area and strengthen the ability to resist damage , the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

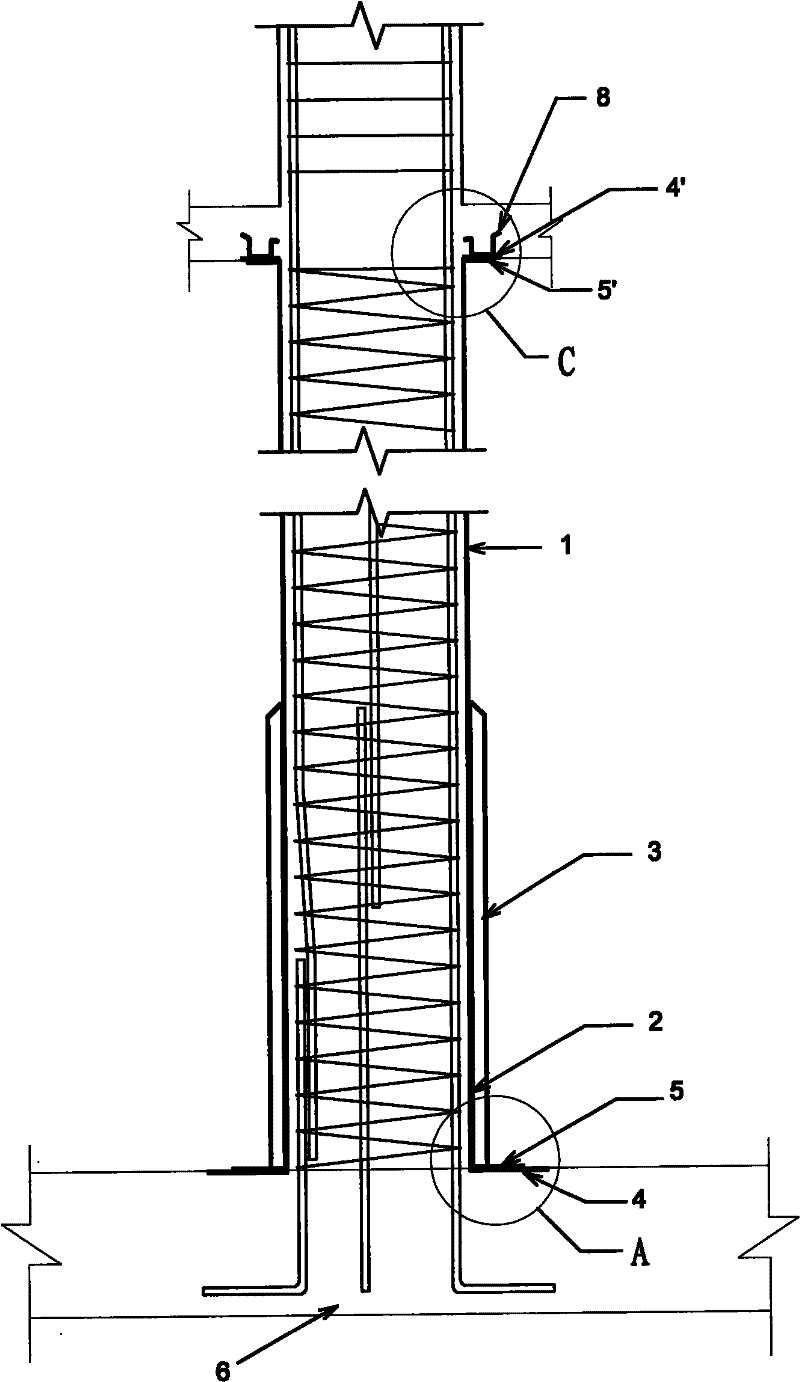

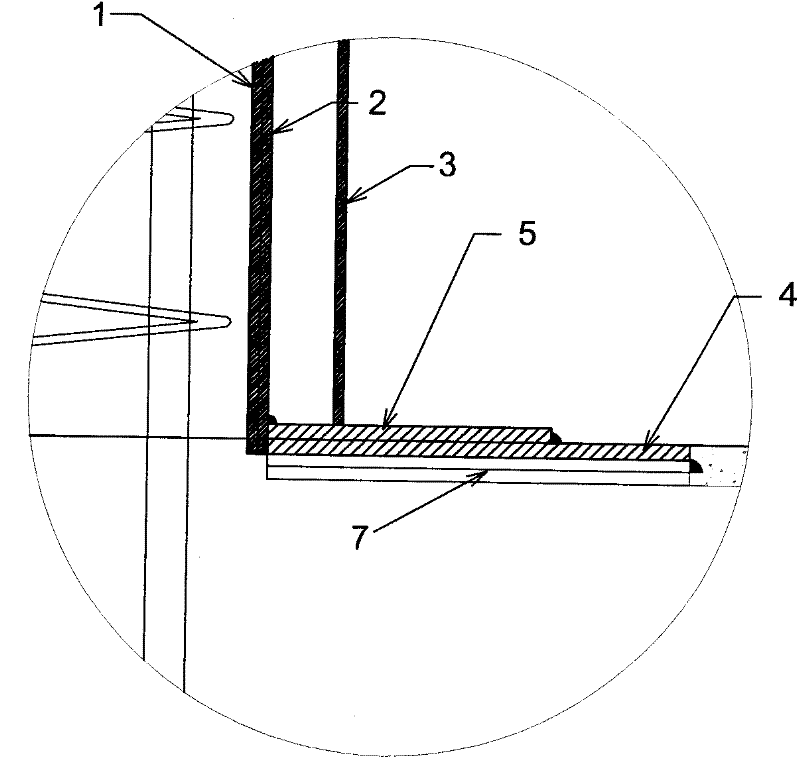

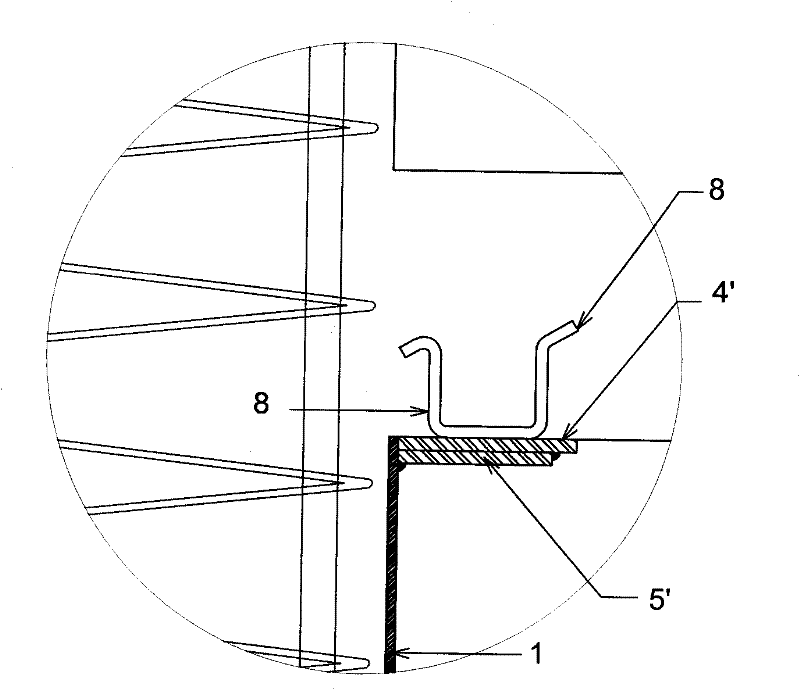

[0031] The reinforced concrete column of the present invention uses spiral stirrups to reduce the elastic deformation of the column itself, and in addition, increases the column's reinforcement ratio to enhance the column's rigidity. Such as figure 1 Shown is the vertical sectional view of reinforced concrete outsourcing steel plate composite explosion-proof column of the present invention, figure 2 with image 3 for figure 1 Enlarged view of nodes A and C in the middle. The outer surface of the reinforced concrete outsourcing steel plate composite explosion-proof column of the present invention is sequentially sleeve-welded with a full-length steel sleeve 1, an additional steel plate 2 and a protective steel plate 3, and the additional steel plate 2 and the protective steel plate 3 are located in the full-length steel sleeve 1. In the lower part of the bottom half of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com