Solidification method of fiber-wound gas cylinder

A technology of winding gas cylinders and curing methods, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., and can solve problems affecting product performance and appearance quality, low curing efficiency, and large energy consumption. Achieve the effect of good performance and appearance quality, short curing time and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with specific examples.

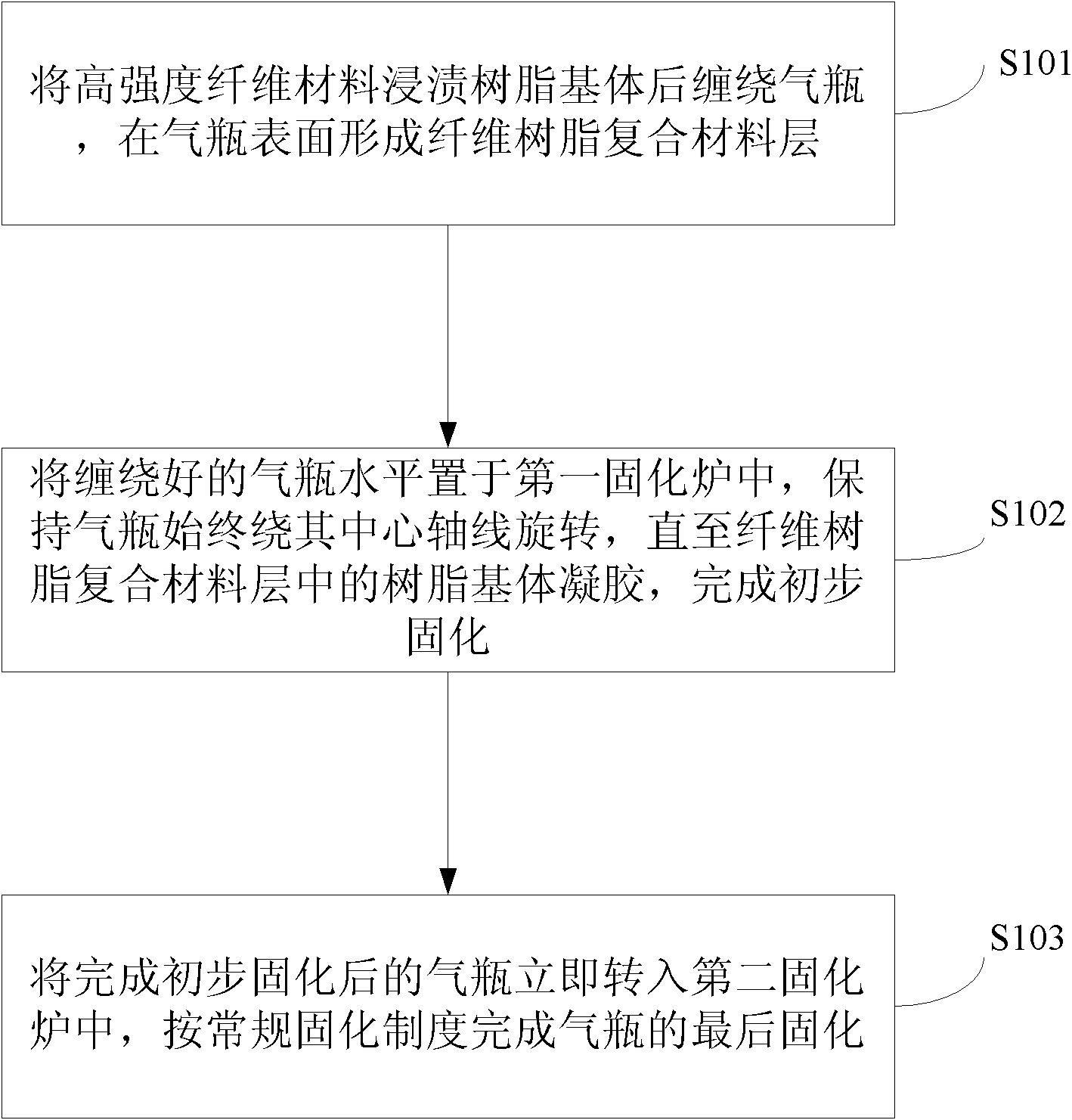

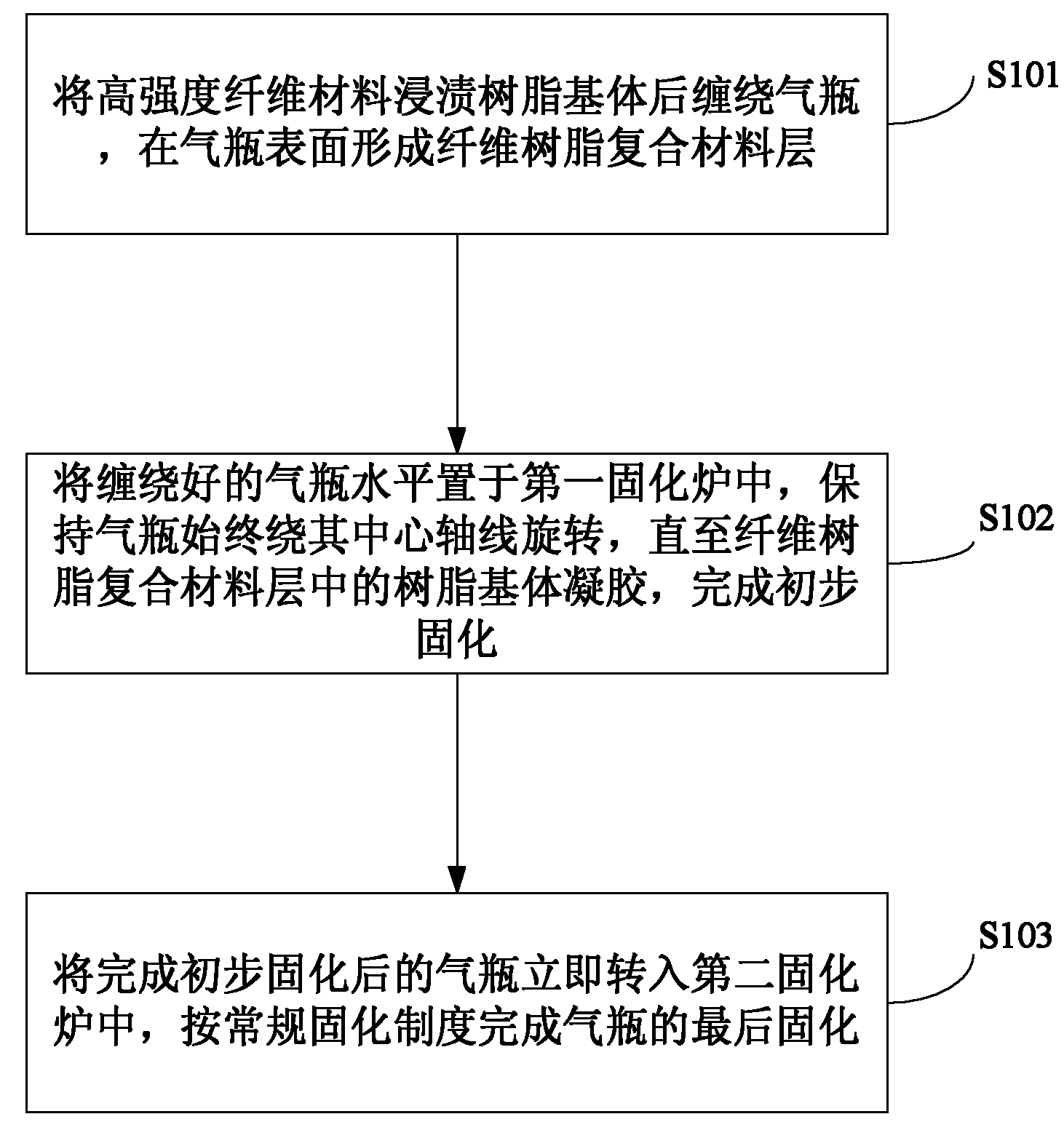

[0016] Such as figure 1 As shown, the curing method of the fiber-wound gas cylinder of the present embodiment comprises the following steps:

[0017] Step S101: impregnating the high-strength fiber material into the resin matrix and wrapping the gas cylinder to form a fiber resin composite material layer on the surface of the gas cylinder. The wound gas cylinder can be a ring wound gas cylinder or a fully wound gas cylinder.

[0018] Step S102: Place the wound gas cylinder horizontally in the first curing furnace, keep the gas cylinder rotating around its central axis, until the resin matrix in the fiber-resin composite material layer gels, and completes preliminary curing. Specifically, the gas cylinder can be horizontally placed on the gas cylinder support of the rotary curing furnace and connected and fixed with the transmission mechanism, and the transmission m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com