Dual-cylinder dual-return stroke staged combustion device

A staged combustion and double-return technology, which is applied in the direction of combustion methods, combustion equipment, and solid fuel combustion, can solve the problems of poor ignition performance of the burner, inability to rotate the combustion flame, and inability to fully burn, etc., to solve ignition difficulties, The effect of sufficient heat release and height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

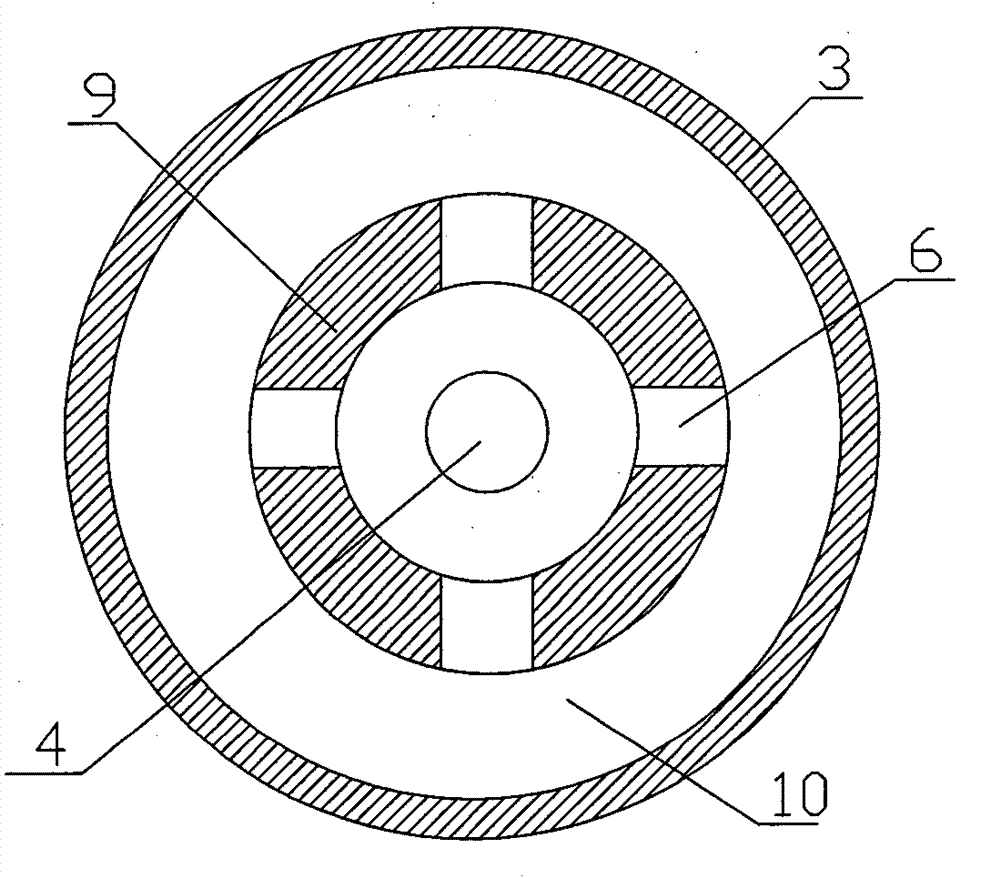

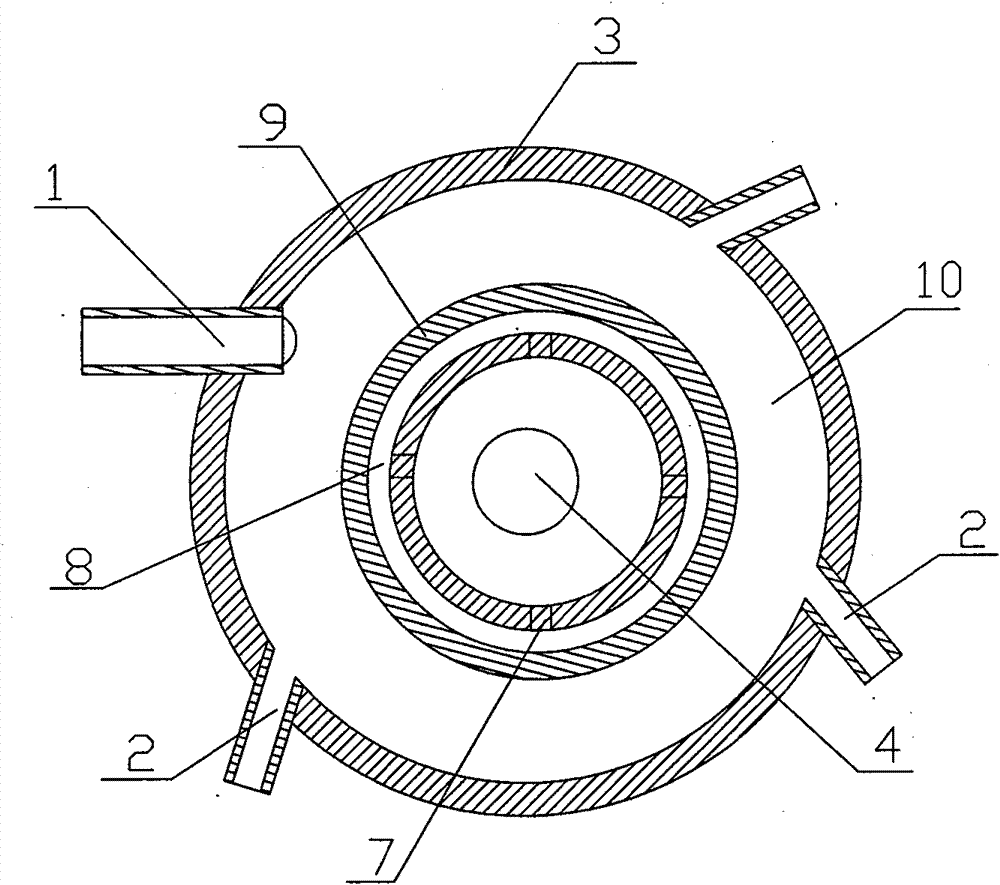

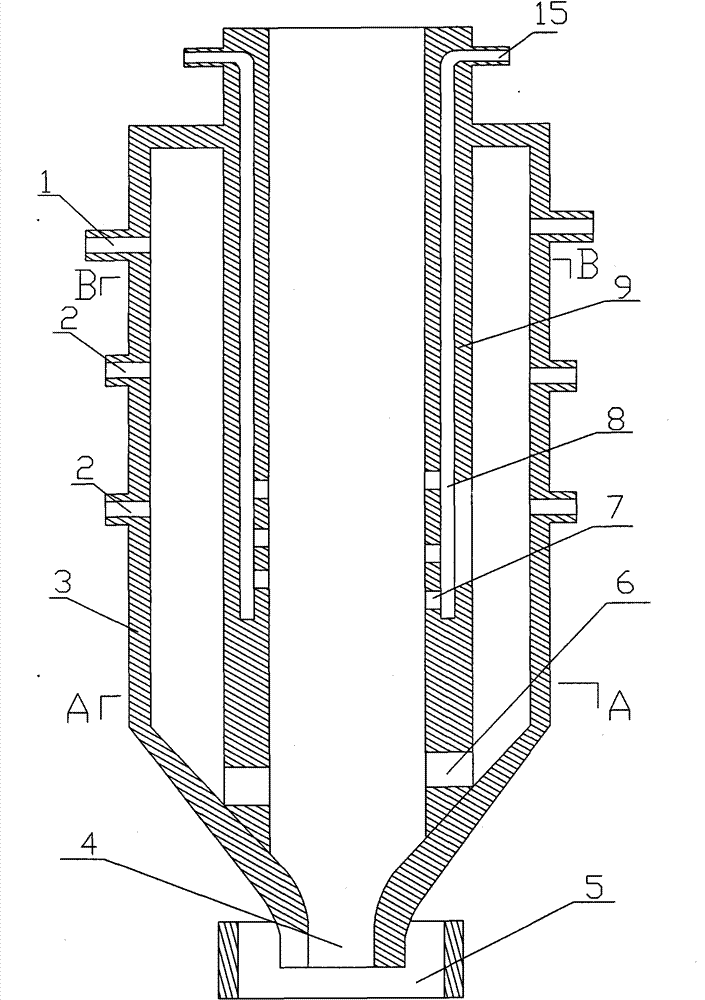

[0022] A double-barrel double-return staged combustion device, such as Figure 1~3 As shown, comprising the outer cyclone combustion tube 3, at least one combustion lance 1 that injects fuel into the outer cyclone combustion tube at a high speed is provided on the upper side of the outer layer cyclone combustion tube, and the side wall of the outer layer cyclone combustion tube is provided with at least one One primary tangential air supply port 2. The outer cyclone combustion tube 3 is provided with an inner cyclone combustion tube 9, and the side wall of the inner cyclone combustion tube 9 forms a closed combustion interlayer 10 with the side wall of the outer cyclone combustion tube 3. In the combustion interlayer At least one flame through hole 6 is arranged on the side wall of the inner cyclone combustion cylinder at the bottom of 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com