Measuring method of package thermal strain of radio frequency micro electromechanical system device

A microelectromechanical system and device packaging technology, which is applied in the field of measuring thermal strain of radio frequency microelectromechanical system device packaging, can solve the problem that the measurement accuracy is affected by the structural shape and scale, the measurement accuracy is affected by the grating scale and accuracy, and the measurement accuracy and low sensitivity, to achieve online measurement, reduce measurement costs, and simplify the measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

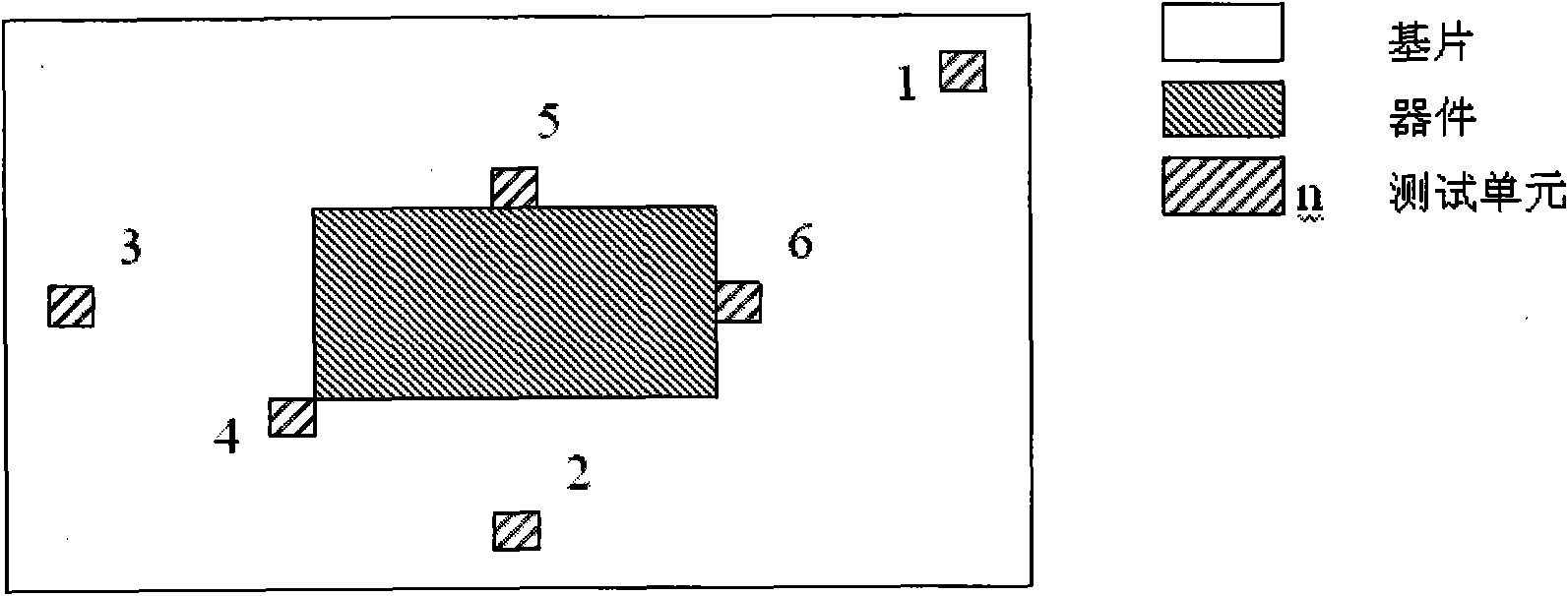

[0018] Example: as figure 1 , image 3 and Figure 4 As shown, a method for measuring thermal strain of a radio frequency MEMS device package includes the following steps:

[0019] (1) Simultaneous production of test units with RF MEMS devices:

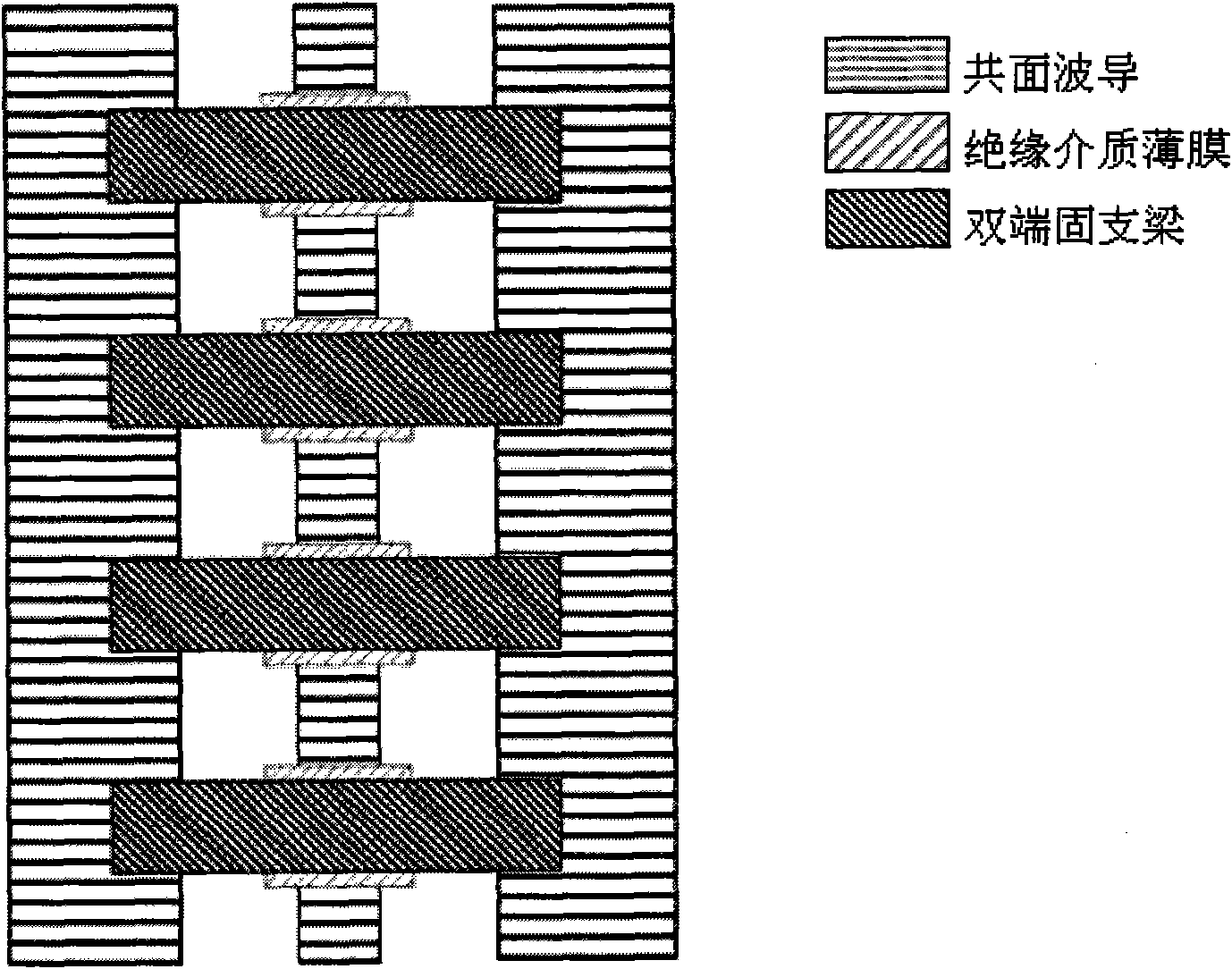

[0020] Coplanar waveguide is formed by sputtering a metal film on a low-loss substrate and etching it; depositing an insulating dielectric film and etching only the part covering the overlapping area of the coplanar waveguide signal line and the double-ended clamped beam; spin coating sacrificial layer, the anchor area window of the double-ended fixed beam is etched on the sacrificial layer; the metal film is sputtered and etched to form the beam structure, and then thickened by electroplating; finally, the sacrificial layer is removed by wet etching to release the beam structure;

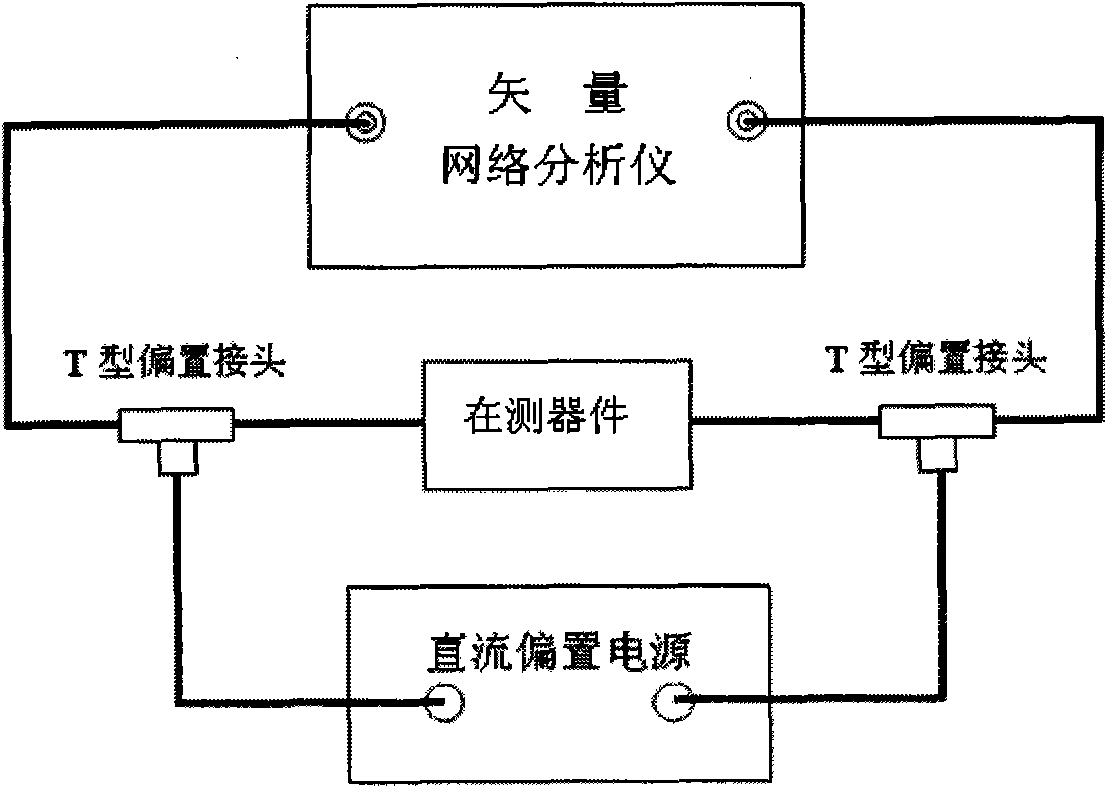

[0021] (2) If figure 2 As shown, a microwave network measurement system consisting of a vector network analyzer, a DC bias power supply, and a T-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com