Thiamphenicol glycinate hydrochloride freeze-dried powder injection and preparation method thereof

A technology of thiamphenicol hydrochloride and freeze-dried powder injection, which is applied in the field of medicine, can solve unscientific problems, and achieve the effects of low related substances, stable quality, easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] prescription

[0126] Name of raw and auxiliary materials Quantity for 1000 sticks (g)

[0127] Thiamphenicol Hydrochloride Glycinate 631.25g

[0128] Add water for injection to 3000ml

[0129] Preparation Process

[0130] 1. Measure 80% of the prescribed amount of water for injection cooled to room temperature, adjust the pH to 1.8-2.4 with hydrochloric acid, add the prescribed amount of thiamphenicol hydrochloride glycinate, stir to dissolve, and add water for injection cooled to room temperature to the full amount.

[0131] 2. Add 0.05% (g / ml) activated carbon to the liquid medicine, stir for 30 minutes, decarburize and filter to obtain the filtrate.

[0132] 3. Measure the pH and content of the intermediate solution.

[0133] 4. 0.22μm microporous membrane filtration.

[0134] 5. Filling.

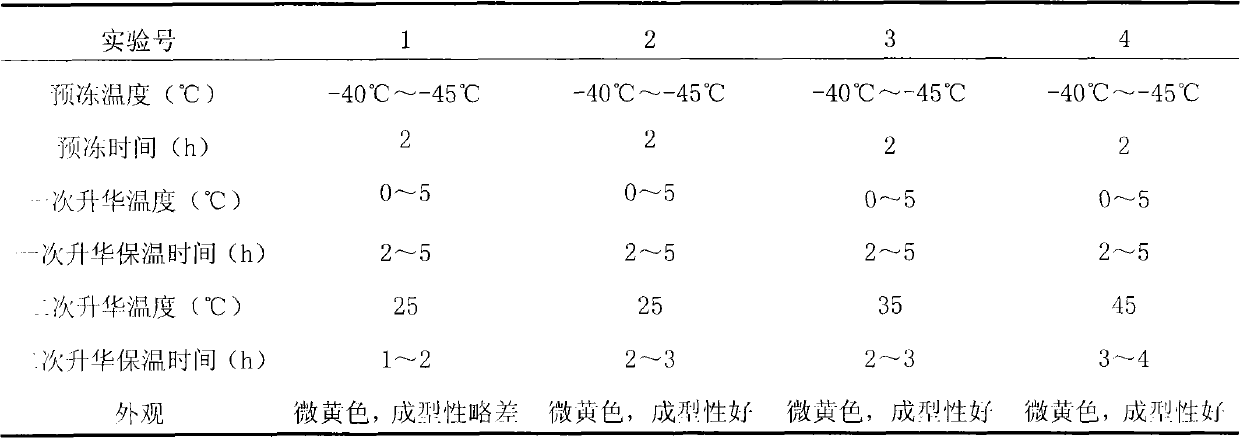

[0135] 6. Freeze-drying:

[0136] (1) Turn on the front box refrigeration to lower the temperature of the product to below -40°C and keep it for 2-3 hours.

[0137] (2) ...

Embodiment 2

[0144] prescription

[0145] Name of raw and auxiliary materials Quantity for 1000 sticks (g)

[0146] Thiamphenicol Hydrochloride Glycinate 631.25g

[0147] Add water for injection to 3000ml

[0148] The preparation process is the same as in Example 1, wherein the temperature of the water for injection is 20° C., and the pH value of the intermediate solution is adjusted to 1.8.

[0149] After testing the intermediate solution and finished product obtained by the above method, the related substances were 0.55% and 0.71% respectively.

Embodiment 3

[0151] prescription

[0152] Name of raw and auxiliary materials Quantity for 1000 sticks (g)

[0153] Thiamphenicol Hydrochloride Glycinate 631.25g

[0154] Add water for injection to 3000ml

[0155] The preparation process is the same as in Example 1, wherein the temperature of the water for injection is 25° C., and the pH value of the intermediate solution is adjusted to 2.0.

[0156] After testing the intermediate solution and finished product obtained by the above method, the related substances were 0.49% and 0.68% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com