High purification method of industrial tail gas containing oxynitride

A technology for industrial tail gas and nitrogen oxides, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., to achieve the effects of increasing oxidation rate, high operating flexibility, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The industrial tail gas treatment capacity is 3000m 3 / h, the inlet concentration of nitrogen oxides is 1000mg / m 3

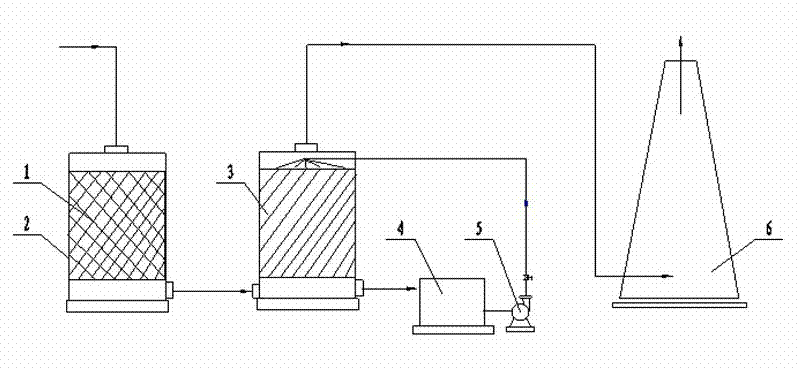

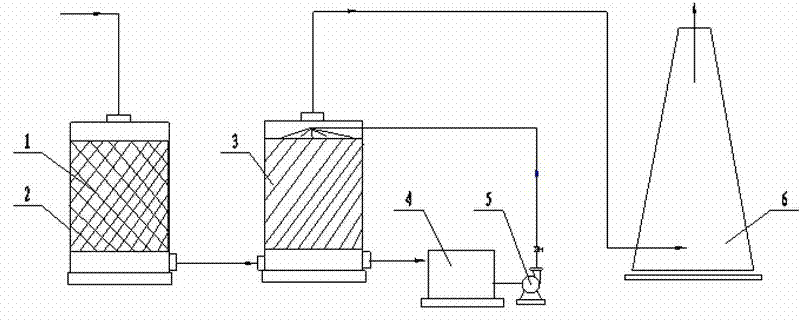

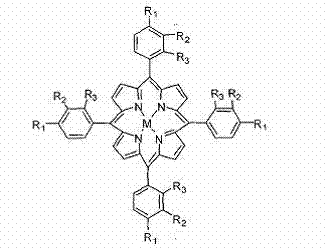

[0027] A method for highly purifying industrial tail gas containing nitrogen oxides, such as figure 1 As shown, comprise the following steps: the industrial tail gas containing nitrogen oxide enters in the oxidation reactor 2 that is filled with immobilized metal porphyrin catalyst 1 from the top, and the volume content of the industrial tail gas containing nitrogen oxide entering the oxidation reactor accounts for the total amount of the reactor. 5% of volume. The metal atom M of the immobilized metalloporphyrin catalyst can be a transition metal Co or Cu, and the substituent R in the structural formula 1 , R 2 , R 3 It can be hydrogen, and the carrier is silica gel or molecular sieve; the residence time of the industrial tail gas containing nitrogen oxides passing through the oxidation reactor filled with metal porphyrin catalyst is 0.1 ...

Embodiment 2

[0028] Example 2: The industrial tail gas treatment capacity is 5000m 3 / h, the inlet concentration of nitrogen oxides is 5000mg / m 3

[0029] A method for highly purifying industrial tail gas containing nitrogen oxides, such as figure 1 As shown, comprise the following steps: the industrial tail gas containing nitrogen oxide enters in the oxidation reactor 2 that is filled with immobilized metal porphyrin catalyst 1 from the top, and the volume content of the industrial tail gas containing nitrogen oxide entering the oxidation reactor accounts for the total amount of the reactor. 5-21% of the volume. The metal atom M of the immobilized metalloporphyrin catalyst can be a transition metal Ni or Zn, and the substituent R in the structural formula 1 , R 2 , R 3 It can be alkoxyl or hydroxyl, and the carrier is zeolite or sepiolite or porous ceramics; the residence time of industrial tail gas containing nitrogen oxides through the oxidation reactor filled with metal porphyrin ...

Embodiment 3

[0030] Example 3: The industrial tail gas treatment capacity is 10000m 3 / h, the inlet concentration of nitrogen oxides is 6000mg / m 3

[0031] A method for highly purifying industrial tail gas containing nitrogen oxides, such as figure 1As shown, comprise the following steps: the industrial tail gas containing nitrogen oxide enters in the oxidation reactor 2 that is filled with immobilized metal porphyrin catalyst 1 from the top, and the volume content of the industrial tail gas containing nitrogen oxide entering the oxidation reactor accounts for the total amount of the reactor. 5-21% of the volume. The metal atom M of the immobilized metalloporphyrin catalyst can be a transition metal Fe or Mn, and the substituent R in the structural formula 1 ,R 2 ,R 3 It can be a hydrocarbon group, and the carrier is polyvinyl chloride or polystyrene; the residence time of the nitrogen oxide-containing industrial tail gas passing through the oxidation reactor filled with a metalloporp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com