Replacement structure of ratchet wrench

A ratchet wrench and wheel groove technology, which is applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of inconvenient replacement and use, insufficient torque resistance, shortened service life, etc., achieve smooth and convenient replacement, avoid loss of components, and improve The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

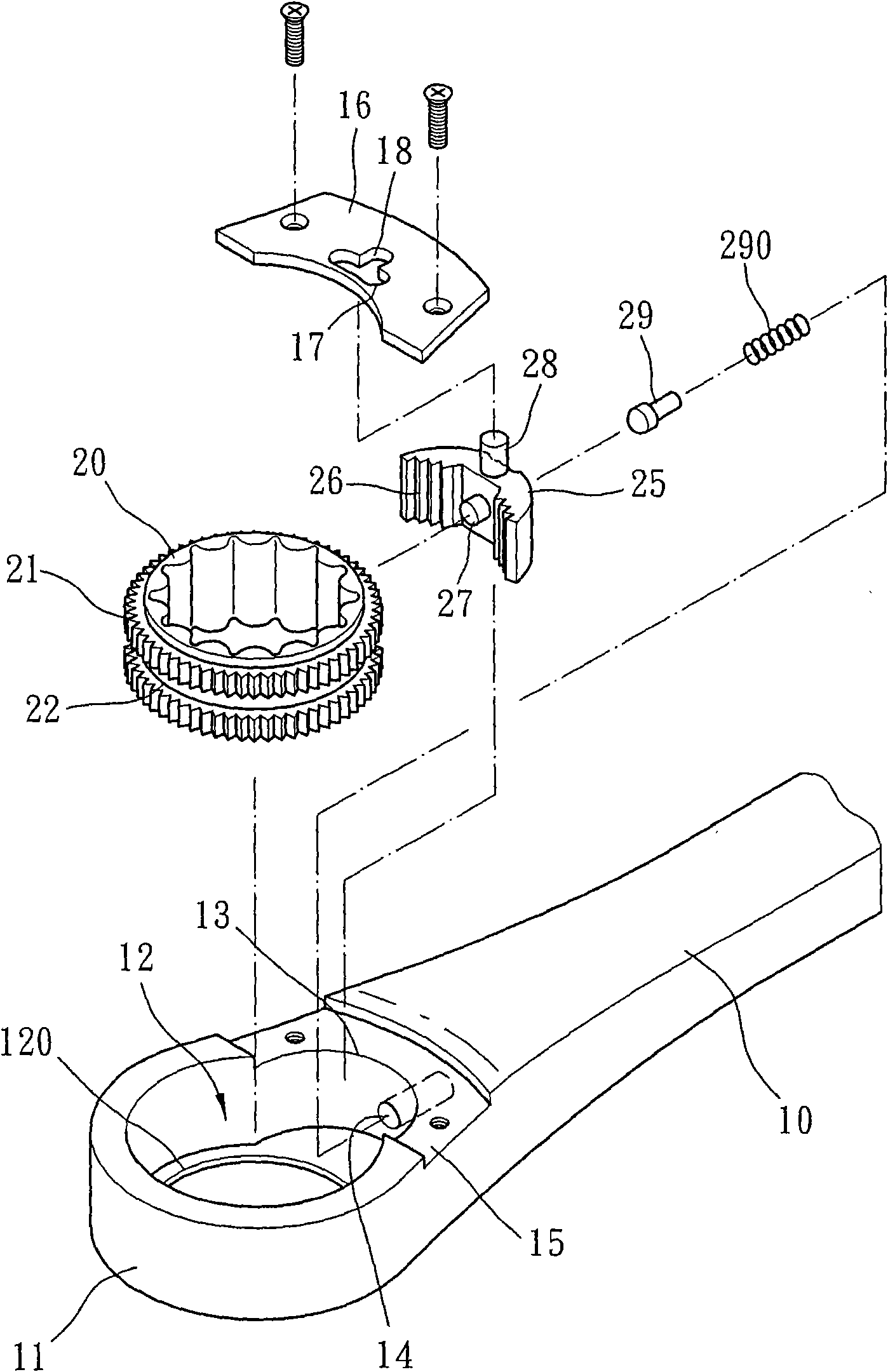

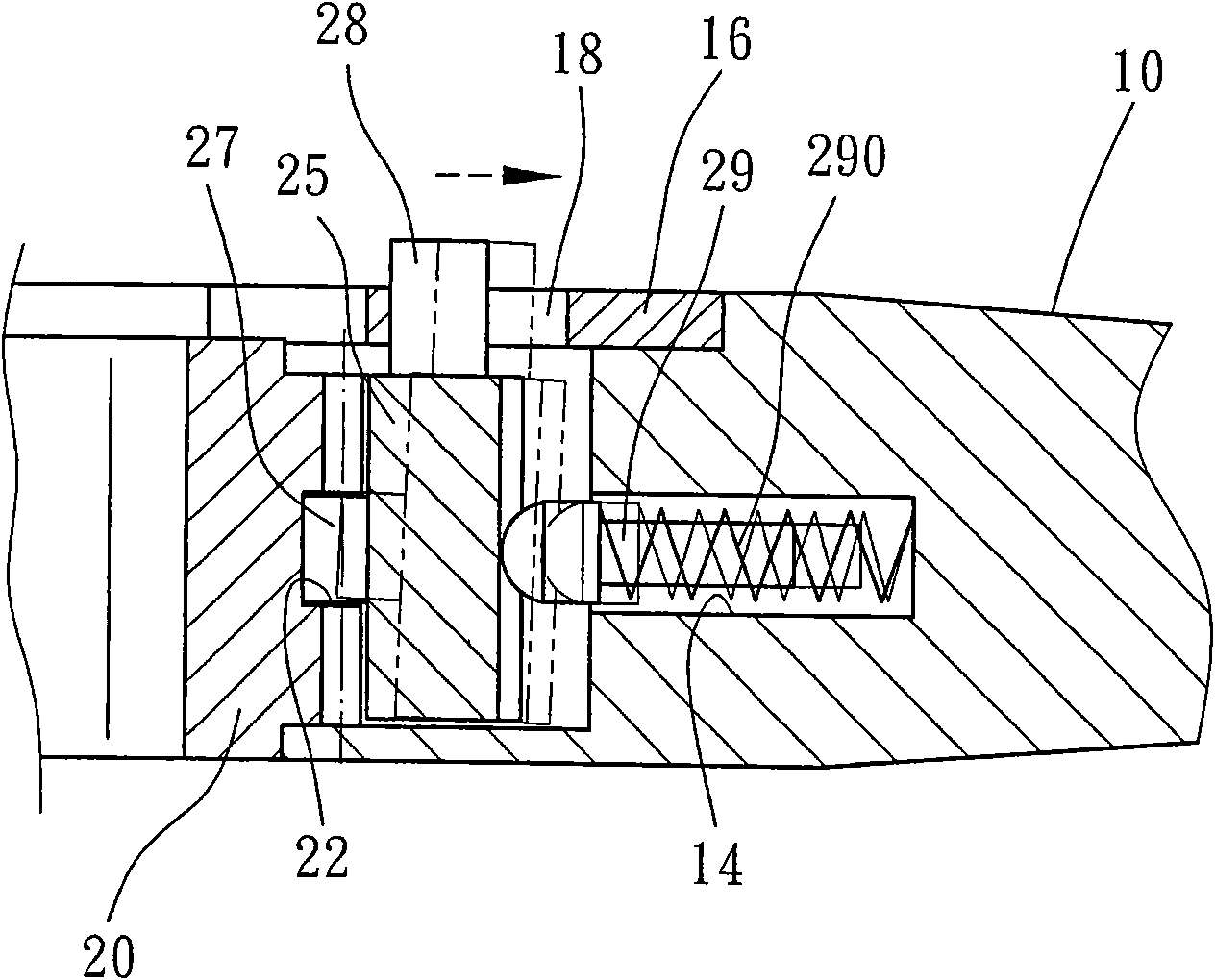

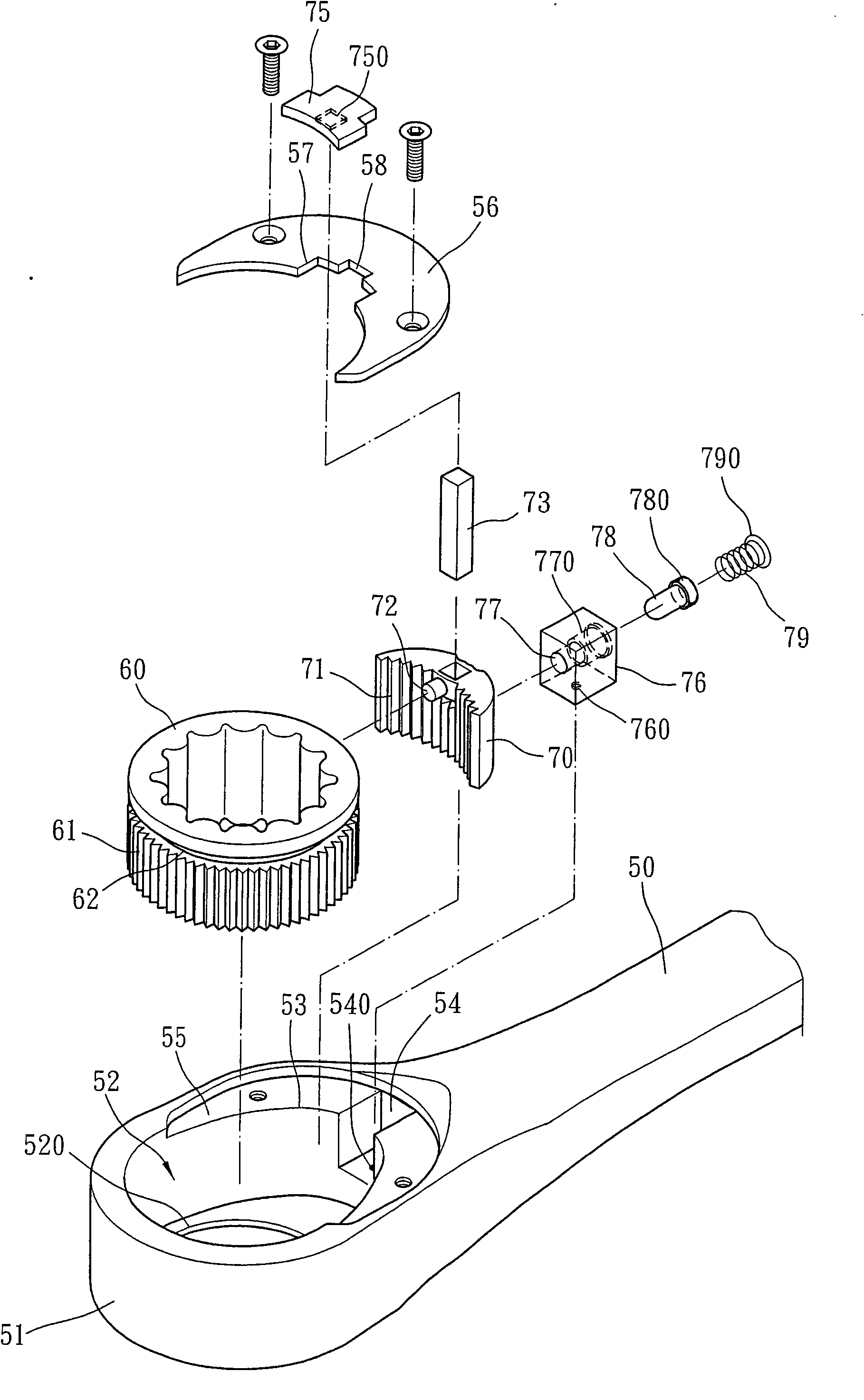

[0058] Ratchet wrench structure of the present invention, as Figure 3 to Figure 5 As shown, it includes a pull lever 50, a set wheel 60 with a nested nut and a stopper 70 for steering the turn of the set wheel 60;

[0059] At least one of the two ends of the lever 50 has a head 51, and the head 51 is formed with a hollow wheel groove 52 for accommodating the aforementioned fitting wheel 60, and the bottom edge of the wheel groove 52 is formed with a groove for the fitting wheel 60 to stick against. The abutting edge 520 and the head 51 form a dial groove 53 on the periphery of the wheel groove 52 adjacent to the lever 50. The dial groove 53 is used for accommodating the aforementioned stopper 70, and the head 51 is formed on the inner wall of the dial groove 53. An accommodating groove 54 extending toward the lever 50 is formed, a recessed positioning hole 540 is formed on the bottom surface of the accommodating groove 54, and a recessed portion 55 is formed on the top surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com