Ink supply device of photogravure press with multiple printing seats

A technology of ink supply device and printing machine, applied in general parts of printing machinery, printing machine, printing and other directions, can solve the problems of time-consuming, affecting production efficiency, long time for changing orders, etc., to facilitate maintenance and improve production efficiency , the effect of convenient movement and position switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are described in detail below.

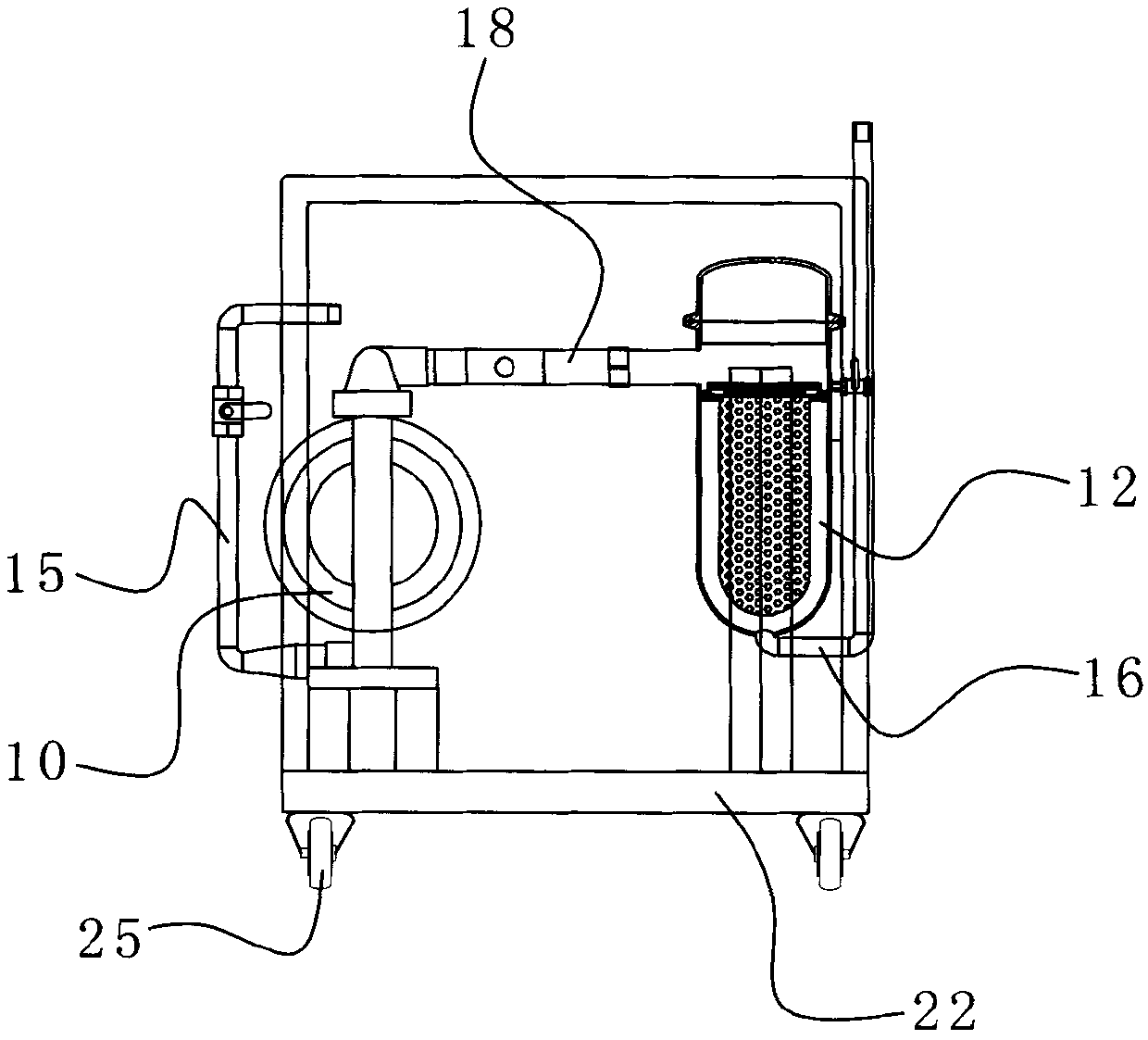

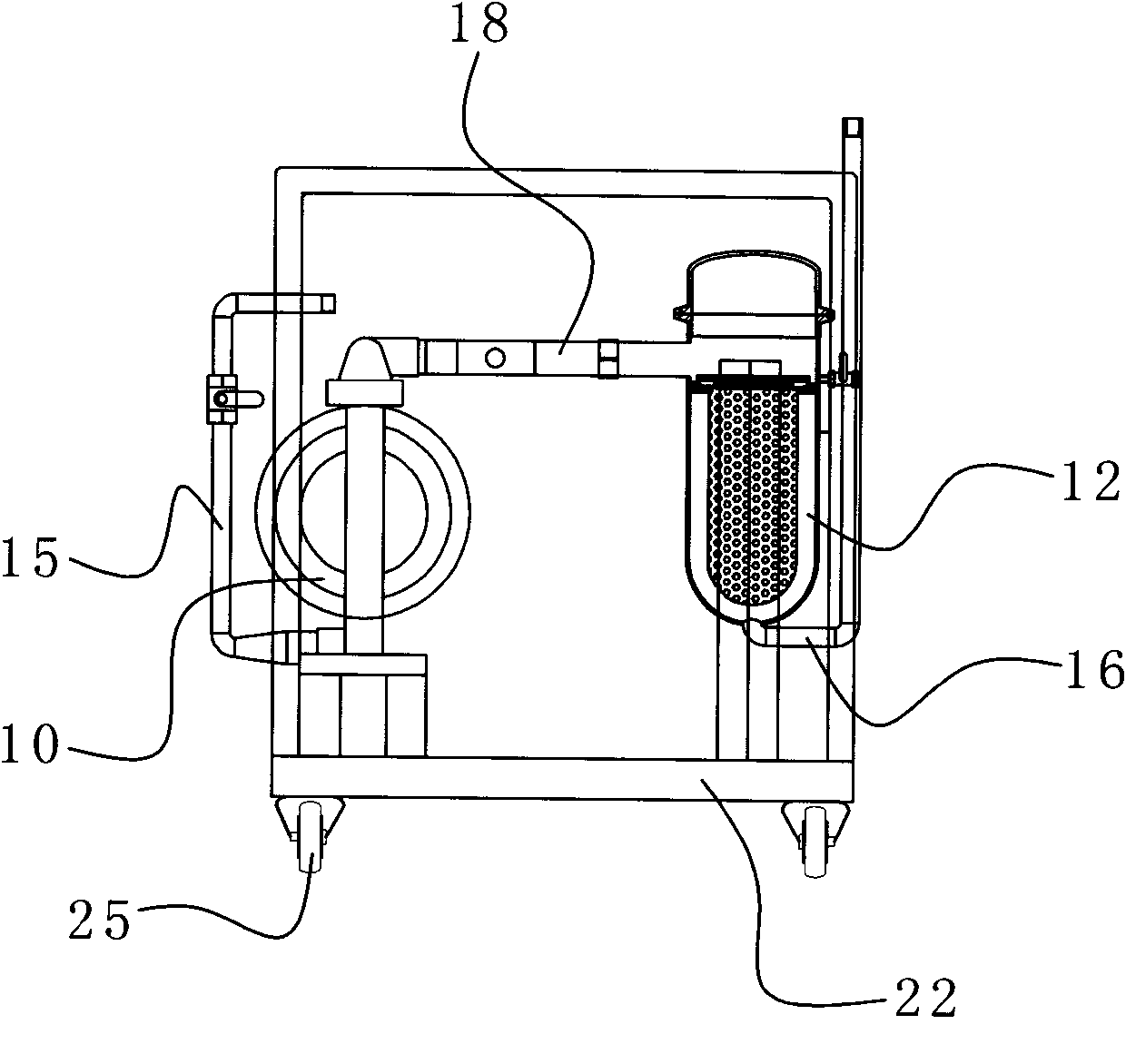

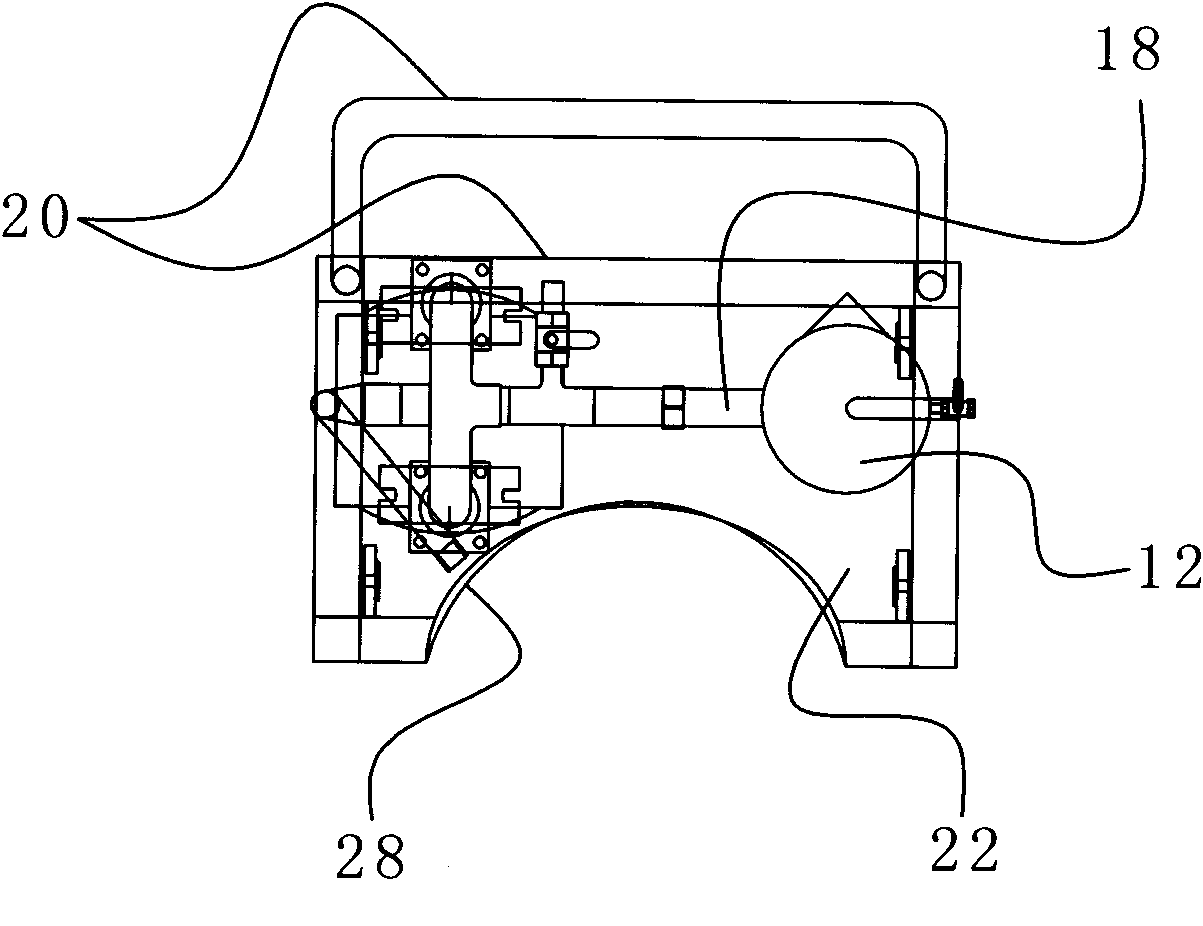

[0016] Such as figure 1 , figure 2 As shown, the present invention is an ink supply device of a multi-print station gravure printing machine, which is used to transport the ink raw material from the ink tank (not shown) to the ink tank of the multi-print station gravure printing machine, and the ink supply device includes a pneumatic diaphragm Pump 10, one end is connected with described pneumatic diaphragm pump 10 and the other end stretches into the ink suction pipe 15 in the described ink barrel, the first end is connected with the outlet of pneumatic diaphragm pump 10 and the other end stretches into described ink groove ( Figure not shown) ink supply tube 16.

[0017] By using the pneumatic diaphragm pump 10 to replace the traditional electric ink pump, since the pneumatic diaphragm pump works through two one-way valves and the pump body, it can provide a lot of power, that is, it can output v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com