Distribution packagaing body and its packagaging product

A packaging body and cover body technology, applied in packaging, wrapping paper, layered products, etc., can solve the problems of oxidative deterioration and insufficient oxygen barrier properties, and achieve the effect of improving oxygen barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100]

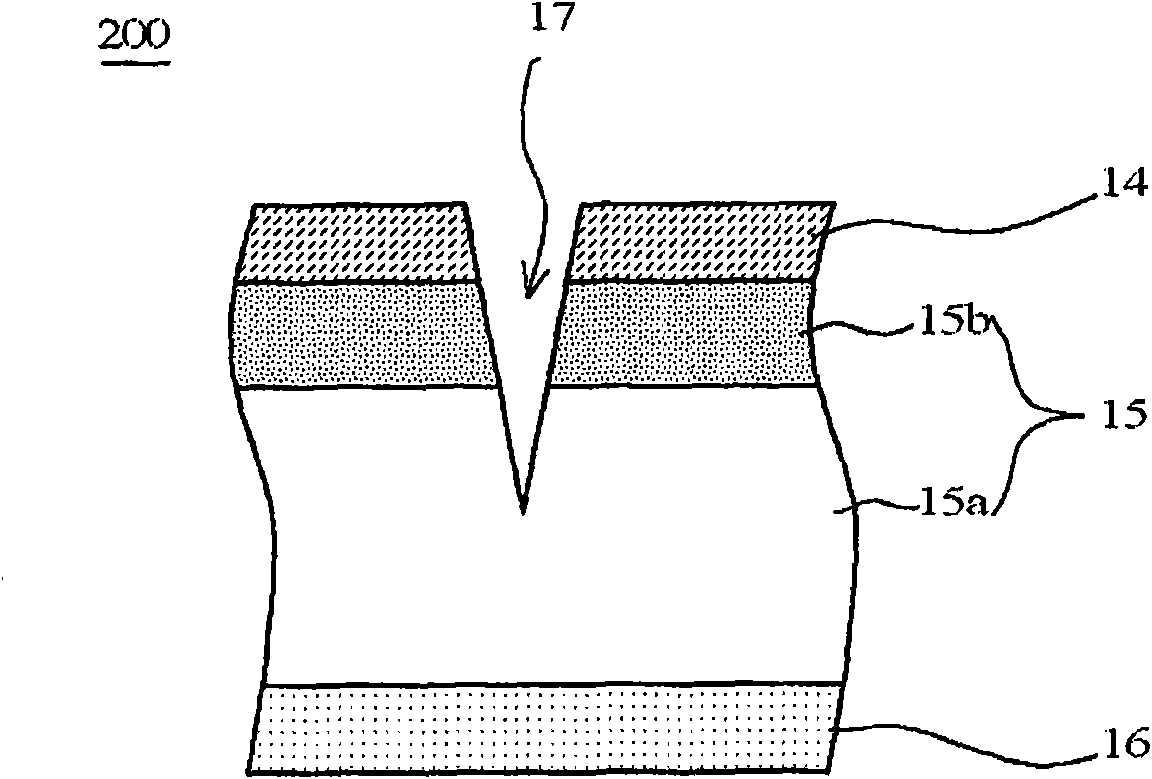

[0101] PET(20μm) / AD(10μm) / EVOH(20μm) / AD(10μm) / HIPS[50 mass%]+GPPS[50 mass%](300μm) / AD(10μm) / LDPE[50 mass%]+HDPE [50% by mass](10μm) / LDPE(10μm)

[0102]

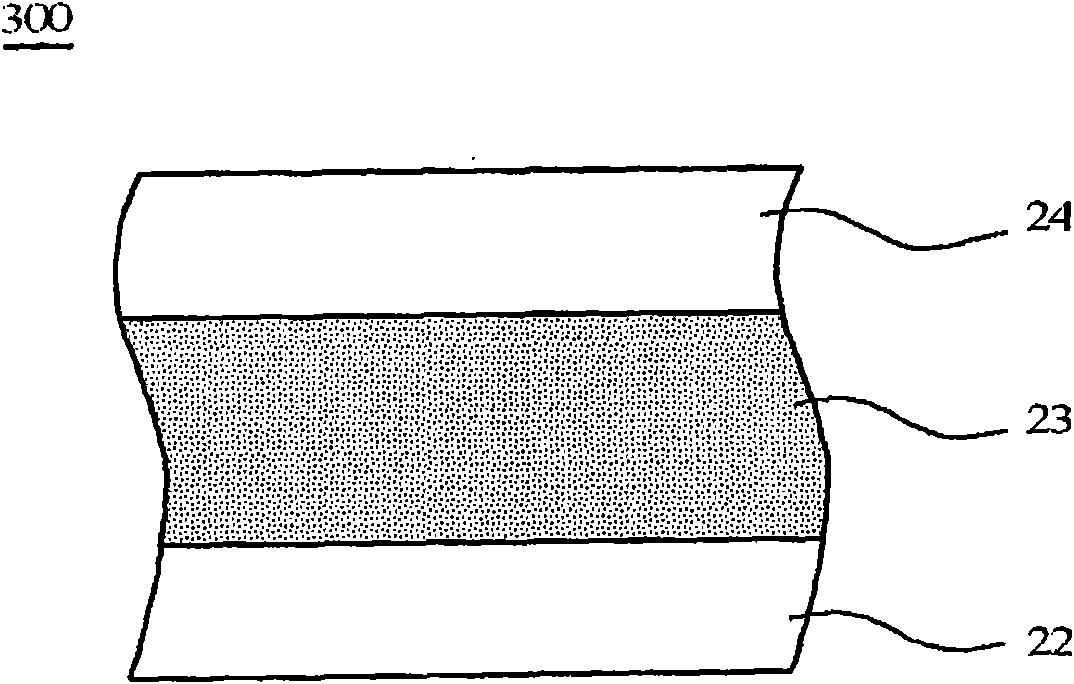

[0103] Ny(20μm) / EVOH(50μm) / AD(20μm) / LDPE(20μm)

[0104] The hard composite sheet and flexible composite film with the above-mentioned layer structure are produced by a co-extrusion method.

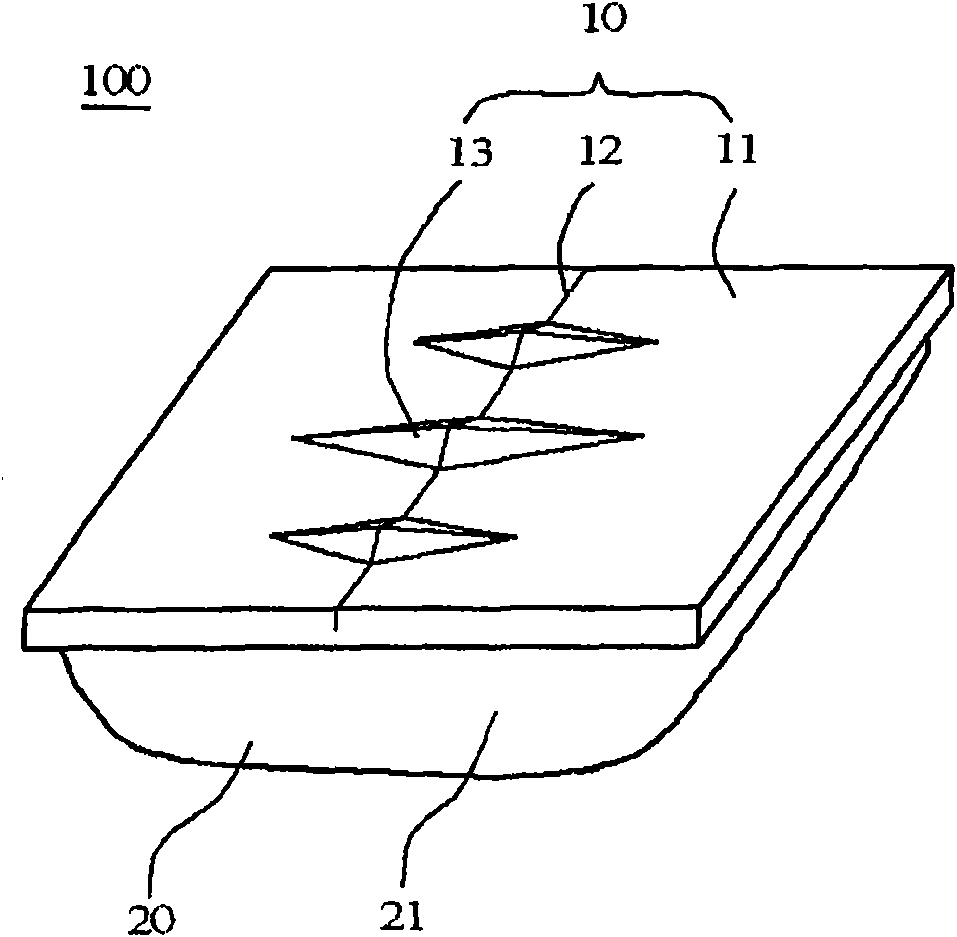

[0105] Next, at a predetermined position of the hard composite sheet, cut from the PET layer side to the PS layer to a depth of 50% of its thickness, and half-cut the hard composite sheet. Next, the half-cut hard composite sheet is heat-molded by a mold molding method to form a convex strip, which forms a discharge port for discharging the contents.

[0106] On the other hand, the flexible composite film is deep drawn to form a bag. After filling the bag with mayonnaise (manufactured by Yuyuichi Co., Ltd.) as a liquid food, it is combined with the rigid composite sheet formed with the convex stripe and heat-sealed. After that, it is c...

Embodiment 2

[0112] Except that the thickness of the EVOH in the rigid composite sheet of Example 1 was changed from 20 μm to 10 μm, in the same manner as in Example 1, a distributive packaged food (mayonnaise) was produced. The layer structure of the rigid composite sheet used is shown below.

[0113]

[0114] PET(20μm) / AD(10μm) / EVOH(10μm) / AD(10μm) / HIPS[50 mass%]+GPPS[50 mass%](300μm) / AD(10μm) / LDPE[50 mass%]+HDPE [50% by mass](10μm) / LDPE(10μm)

Embodiment 3

[0120]

[0121] PET(20μm) / / EVOH(20μm) / / HIPS[80% by mass]+GPPS[20% by mass](300μm) / AD(10μm) / LDPE(10μm) / LDPE(10μm)

[0122]

[0123] Ny(20μm) / EVOH[92% by mass] + oxygen-absorbing resin [8% by mass](50μm) / AD(20μm) / LDPE(20μm)

[0124] The hard composite sheet with the above-mentioned layer structure is produced by combining the co-extrusion method and the dry lamination method. In addition, the above-mentioned flexible composite film is produced by a co-extrusion method. The oxygen barrier layer of the flexible composite film is located in the range of 18-64% from the outer surface of the surface protection layer with respect to the thickness of the flexible composite film.

[0125] Using the above-mentioned rigid composite sheet and flexible composite film, the same method as in Example 1 was used to produce a food (mayonnaise) in a distribution package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com