Oxygen barrier coating for packaging material and preparation method of oxygen barrier coating

A packaging material and oxygen barrier technology, which is applied in the field of food packaging, can solve the problems of water resistance and barrier properties that are not ideal, cannot meet the needs of consumers, and reduce mechanical strength. The effect of oxygen barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

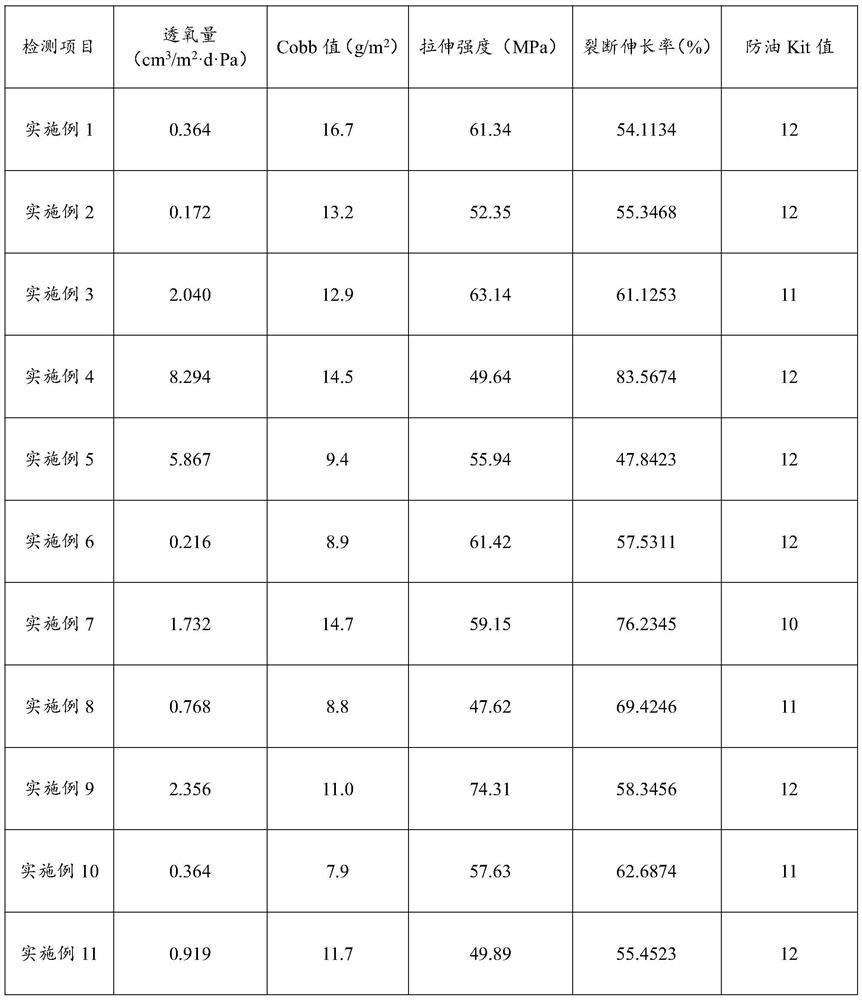

Examples

Embodiment 1

[0026] This embodiment proposes an oxygen barrier coating for packaging materials, and its raw materials are composed of: PVA 8g, glycerin 0.08g, melamine resin 0.16g; prepared by scraping film, and the specific preparation steps are as follows:

[0027] S1: add PVA into 100 mL of deionized water, stir to dissolve, add glycerin, sonicate in an ultrasonic machine for 5 min, vacuum defoaming, add melamine resin, stir evenly, ultrasonically sonicate for 5 min in an ultrasonic machine, and vacuum defoaming to obtain a PVA solution;

[0028] S2: The PVA solution is evenly coated on the surface of the PTFE plate with a measuring rod on the film scraper, the size of the measuring rod is 20 μm, the number of coating layers is 3, and the coating weight is 13 g / m 2 ;

[0029] S3: The obtained material is placed in an oven to dry, and the film is peeled off to obtain the final product.

Embodiment 2

[0031] This example proposes an oxygen barrier coating for packaging materials, the raw material of which is composed of: PVA 8g, starch 2g, glycerin 0.08g, melamine resin 0.16g; it is prepared by scraping the film, and the specific preparation steps are as follows:

[0032] S1: Add starch into 100 mL of deionized water and stir to gelatinize at 80°C, add PVA into it, stir to dissolve, add glycerin, ultrasonicate for 5 minutes in an ultrasonic machine, vacuum defoaming, add melamine resin, stir evenly, and then put it in an ultrasonic machine Ultrasonic 5min, vacuum defoaming, obtain PVA solution;

[0033] S2: The PVA solution is evenly coated on the surface of the PTFE plate with a measuring rod on the film scraper, the size of the measuring rod is 20 μm, the number of coating layers is 3, and the coating weight is 13 g / m 2 ;

[0034] S3: The obtained material is placed in an oven to dry, and the film is peeled off to obtain the final product.

Embodiment 3

[0036] This example proposes an oxygen barrier coating for packaging materials, the raw material of which is composed of: PVA 9g, starch 2g, polyethylene glycol 0.27g, illite 0.45g; it is prepared by scraping film, and the specific preparation steps are as follows :

[0037] S1: Add starch into 200 mL of deionized water and stir to gelatinize at 80 °C, add PVA into it, stir to dissolve, add polyethylene glycol, sonicate for 5 minutes in an ultrasonic machine, vacuum defoaming, add illite, stir evenly, and then sonicate Ultrasonic in the machine for 5min, vacuum defoaming to obtain PVA solution;

[0038] S2: The PVA solution is evenly coated on the surface of the PTFE plate with a measuring rod on the film scraper, the size of the measuring rod is 20 μm, the number of coating layers is 2, and the coating weight is 9 g / m 2 ;

[0039] S3: The obtained material is placed in an oven to dry, and the film is peeled off to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com