Method for preparing bioflocculant and use thereof

A technology of biological flocculants and strains, applied in the field of preparation of biological flocculants, can solve the problems of high production cost, low flocculation activity, long fermentation cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation method of bioflocculant

[0036] The invention provides a preparation method of a biological flocculant, which comprises culturing the bacterial strain Penicillium funiculosum in a fermentation medium to obtain a fermented liquid; centrifuging the fermented liquid to remove mycelia to obtain a supernatant; the supernatant After mixing with ethanol, let it stand still, centrifuge, and take the precipitate to get the bioflocculant.

[0037] The fermentation medium is a liquid medium with neutral pH, preferably pH6.0-8.0; more preferably pH6.5-7.5. It contains nutrients necessary for the growth and metabolism of Penicillium funiculatus, such as but not limited to glucose, sodium nitrate, phosphate and the like.

[0038] The fermentation condition is the culture condition under the shake flask culture state, the pH is neutral, preferably pH6.0-8.0; the inoculum size is 1%, preferably 0.5%-2%; the culture temperature is 25 ℃-30℃, preferably 28℃; the rotation sp...

Embodiment 1

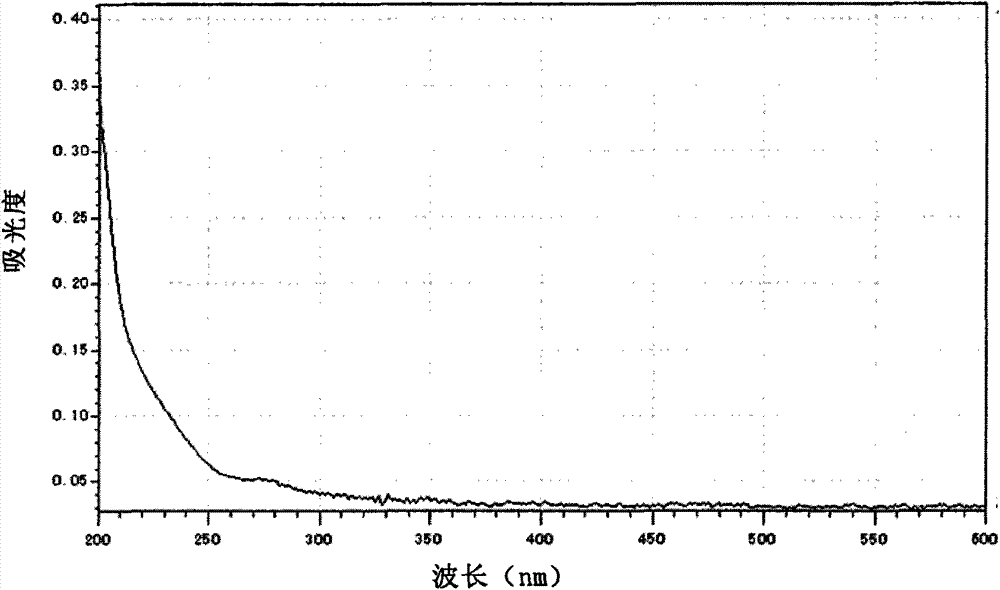

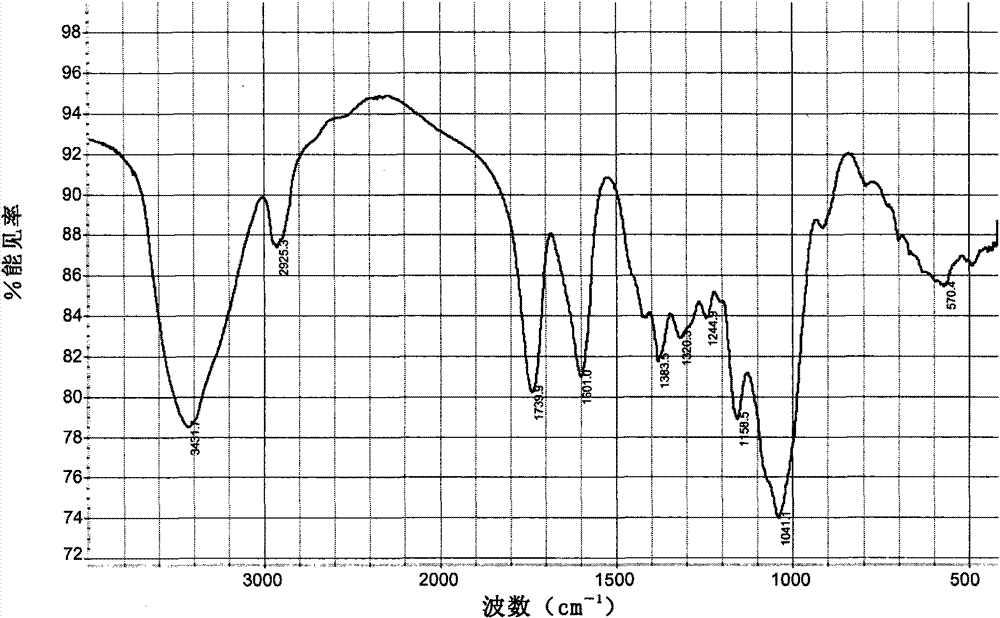

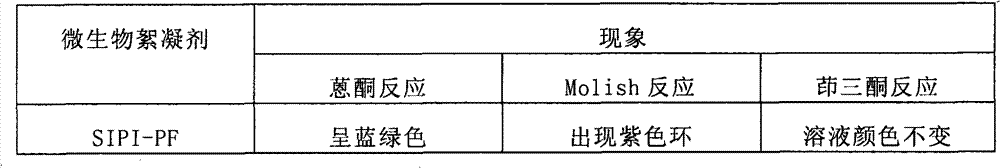

[0055] Preparation of bioflocculant (SIPI-PF)

[0056] 1. Strains

[0057] Penicillium funiculosum (Penicilllium funiculosum) can be purchased from China General Microorganism Culture Collection Center, and the strain preservation number is CGMCC 3.5199

[0058] 2. Fermentation process

[0059] Seed medium (gL -1 ) (purchased from Sinopharm Chemical Reagent Co., Ltd.): sucrose 30, NaNO 3 2, KCl 0.5, K 2 HPO 4 1. MgSO 4 .7H 2 O0.5, FeSO 4 0.01, pH7.2.

[0060] Liquid fermentation medium (gL -1 ) (purchased from Sinopharm Chemical Reagent Co., Ltd.): Glucose 10, NaNO 3 0.5,K 2 HPO 4 2.5, KH 2 PO 4 1. MgSO 4 .7H 2 O 0.2, NaCl 0.1, pH 7.0,

[0061] All the above media were sterilized at 121°C and 0.1MPa for 30min.

[0062] The fermentation conditions are: initial pH 7.0, inoculum size 1%, 28° C., 150 rpm, shaking culture for 60 h.

[0063] 3. Extraction of bioflocculant

[0064] The fermentation broth was centrifuged at 8000rpm for 10min to remove the myc...

Embodiment 2

[0087] Application of bioflocculant

[0088] The cultured fermentation broth was centrifuged to remove mycelium, and the supernatant was retained as flocculant SIPI-PF. Add 90ml of the solution to be flocculated (such as kaolin suspension, bacterial fermentation broth, activated sludge, etc.) into a 100ml graduated cylinder, 5mLw (CaCl 2 )=1% aqueous solution, add SIPI-PF liquid according to different dosage (%, v / v), add distilled water to 100mL, adjust pH to 8.0, pour into 150mL beaker, mix, stir for 3min, let stand for 5min , absorb the supernatant and measure the absorbance (A) at 550nm of the SP-756PC spectrophotometer, and use the absorbance (A) without flocculant 0 ) as a control to determine the flocculation activity of the flocculant, expressed in terms of flocculation rate:

[0089]

[0090] The results are shown in Table 2-4.

[0091] Table 2 The flocculation effect of SIPI-PF on kaolin suspension

[0092] SIPI-PF dosage

(%, v / v)

0.1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com