Water/heat meter with a dispenser casing and method for producing a dispenser casing

A heat meter and transmitter technology, applied in liquid/fluid solid measurement, heating method, and heat measurement, etc., can solve the problems of high price, low strength, low market acceptance, etc., and achieve high production efficiency and large lasting load capacity. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

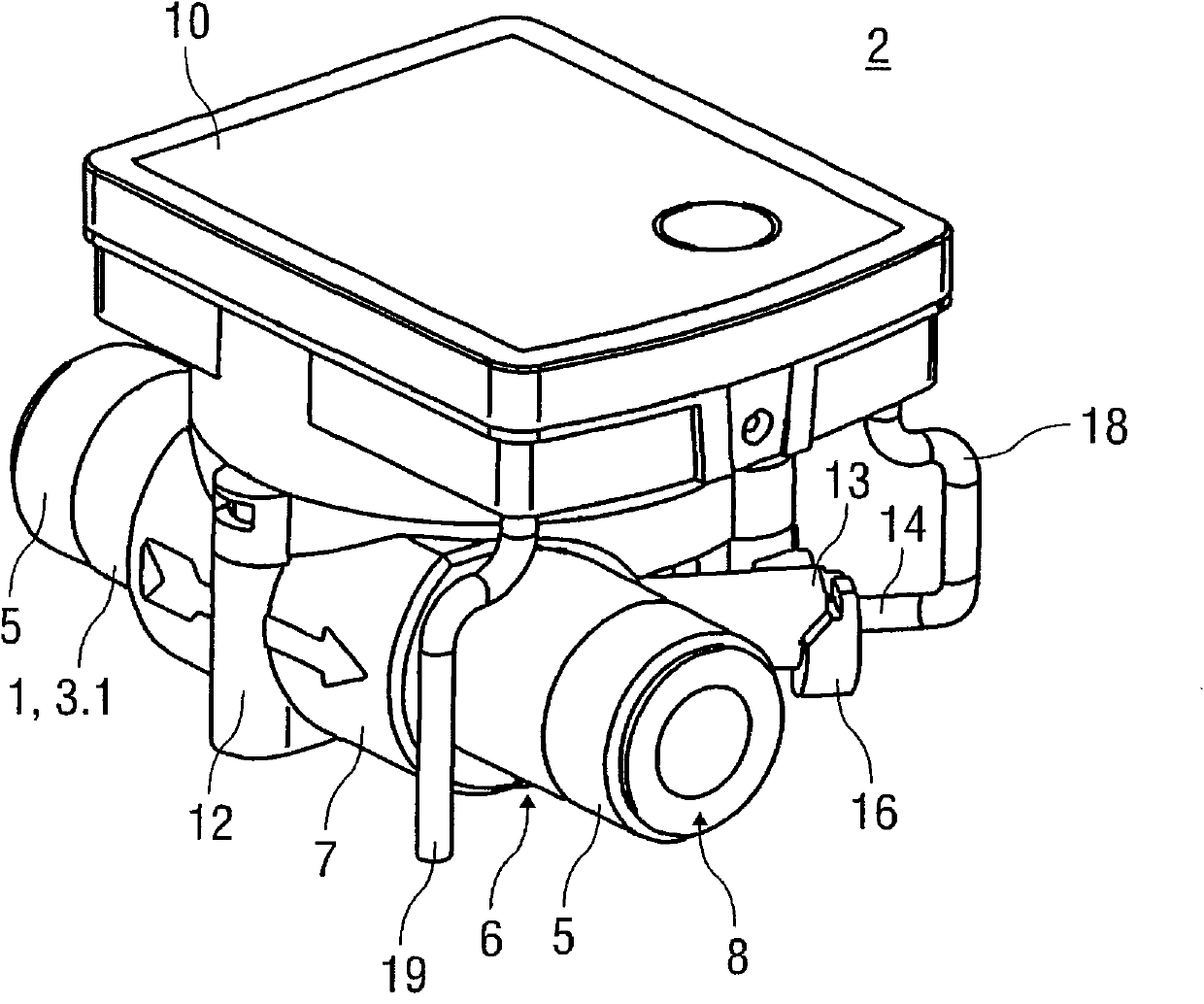

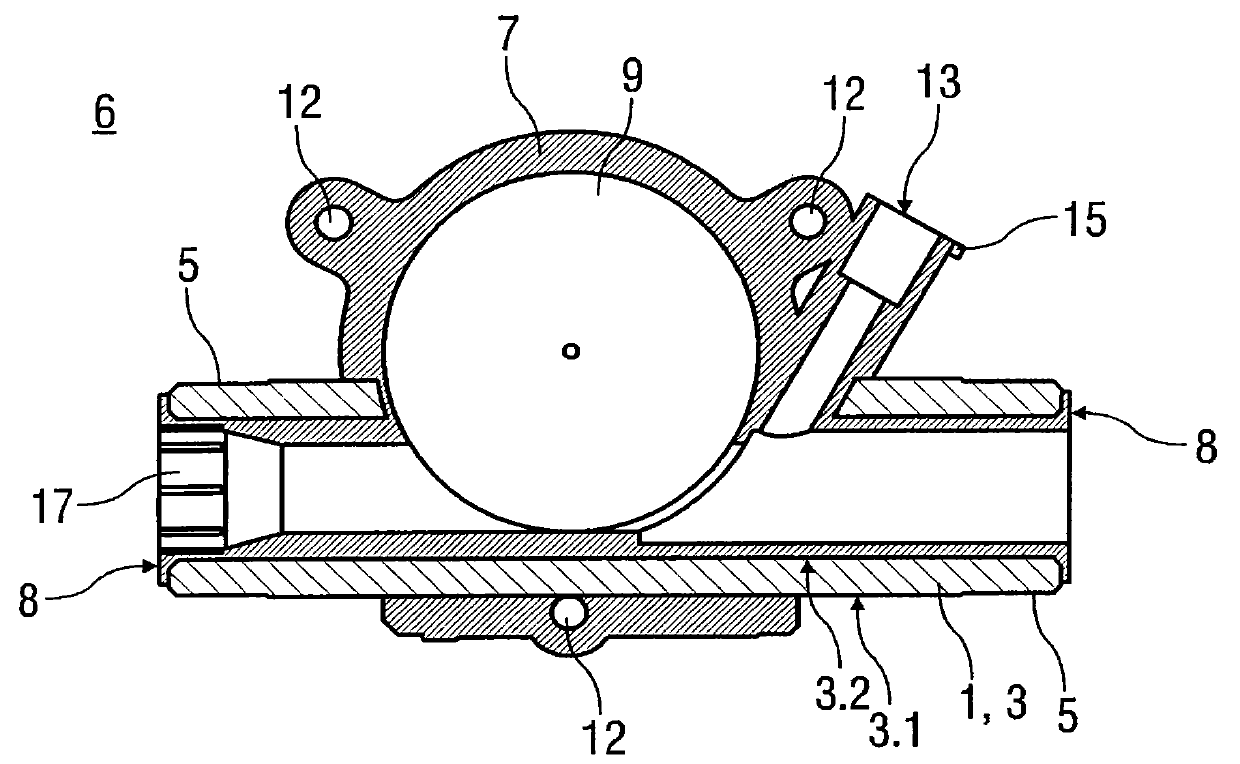

[0027] figure 1 A perspective view of the metal pipe 1 is shown. The metal tube 1 is preferably made of steel because the cost of steel is relatively low and the price fluctuation is less than that of brass used for water / heat meters 2 under the prior art conditions. The wall 3 of the metal tube 1 has an opening 4 which is preferably in the middle of the longitudinal extension of the metal tube 1. For example, the opening 4 can be processed in the metal pipe 1 by punching or milling.

[0028] The two ends of the metal pipe 1 each have threads 5 arranged on the outer wall 3.1 of the metal pipe 1 as a device for connecting to the pipeline system, for example, threads can be machined in the outer wall 3.1.

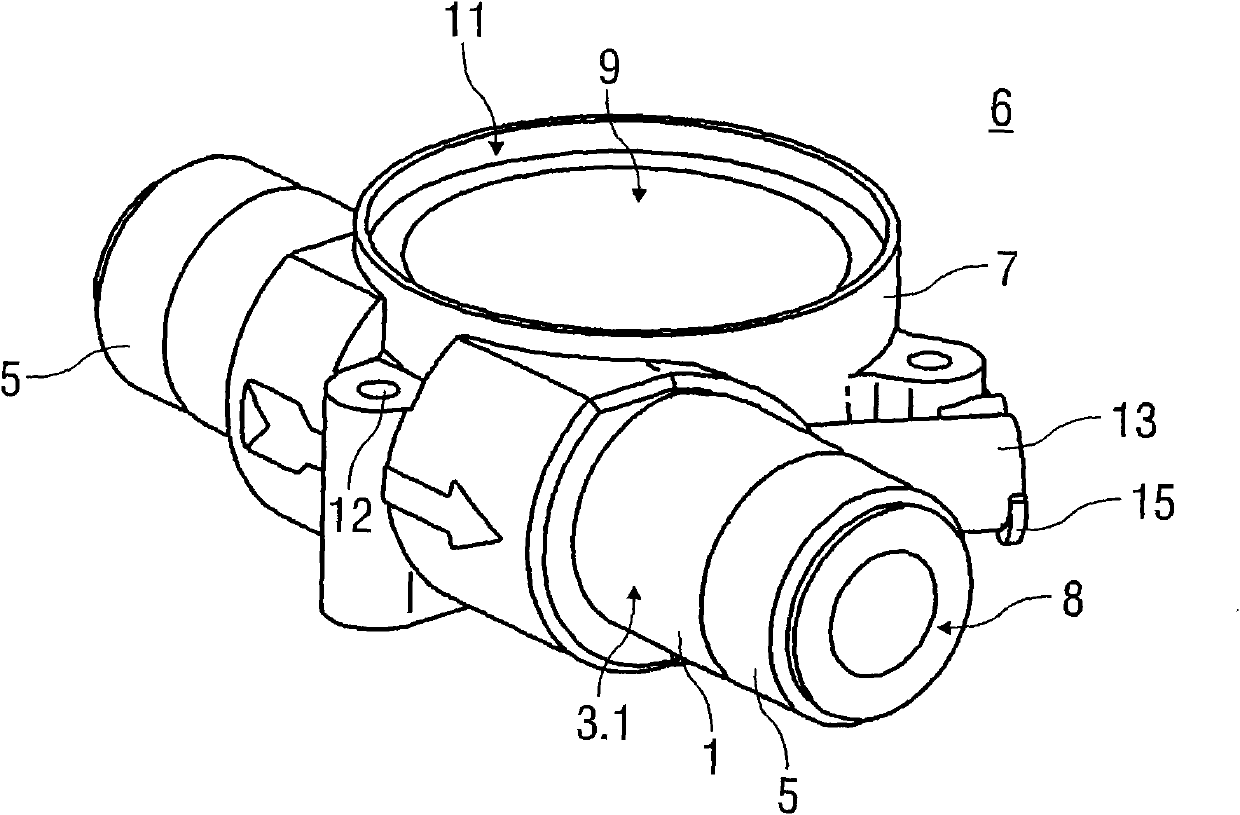

[0029] Put the metal tube 1 processed in this way into an injection mold, and then pour or inject the plastic into the injection mold, so that the attached parts can be mass-produced at low cost. figure 2 The transmitter housing 6 shown. Attached image 3 Shown is a cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com