Assembly type ceiling leveling installation structure

An installation structure and prefabricated technology, applied in the direction of ceilings, building components, building structures, etc., can solve problems that do not conform to the decoration concept of green environmental protection, cannot realize the construction method, and the cost of decoration materials is high, so as to solve the waste of materials and improve Construction efficiency and reduction of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

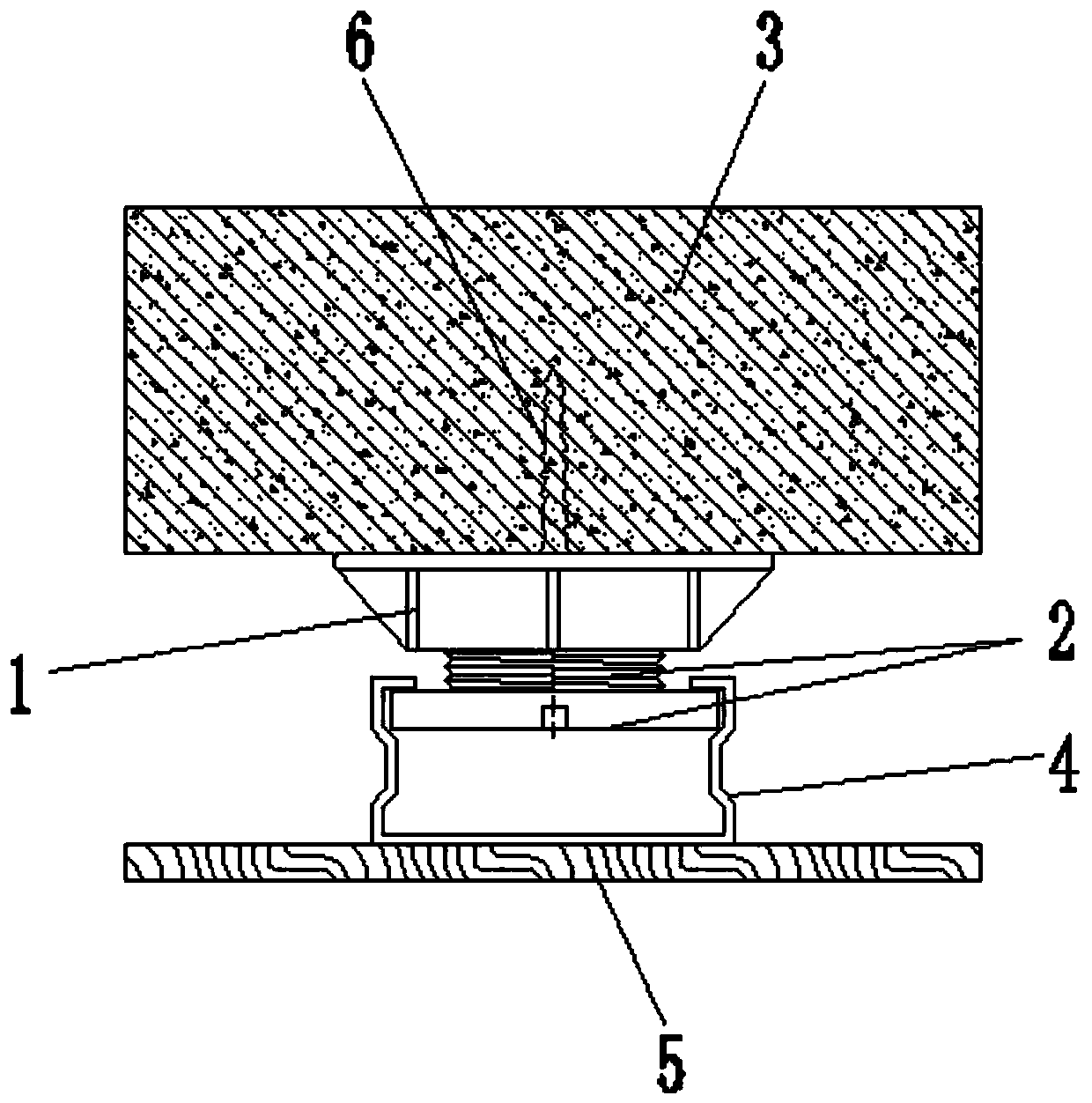

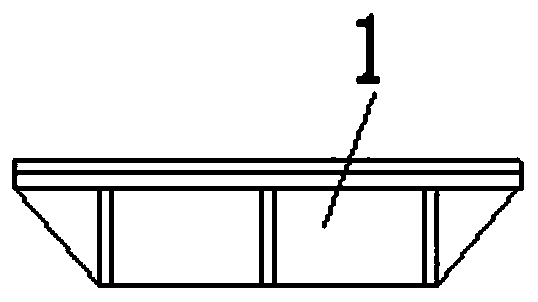

[0035] see figure 1 , the figure shows a prefabricated suspended ceiling leveling installation structure provided by Embodiment 1 of the present invention, including: a leveling connector, which includes a leveling base 1 and a central connector 2, and the top of the leveling base 1 is fixedly connected to the top of the wall 3 , the central connecting piece 2 is located below the leveling base 1, and the two are screwed together; the keel 4 is clamped with the central connecting piece 2; the ceiling plate 5 is fixedly connected to the bottom of the keel 4. Wherein, the leveling base 1 is connected with the top of the wall 3 through screws 6 or expansion bolts.

[0036] An assembled suspended ceiling leveling installation structure provided in this embodiment mainly includes a leveling connector, a keel 4 and a ceiling plate 5, wherein the leveling connector includes a leveling base 1 and a central connector 2, and the leveling base 1 is fixed on The top of the wall 3, the ce...

Embodiment 2

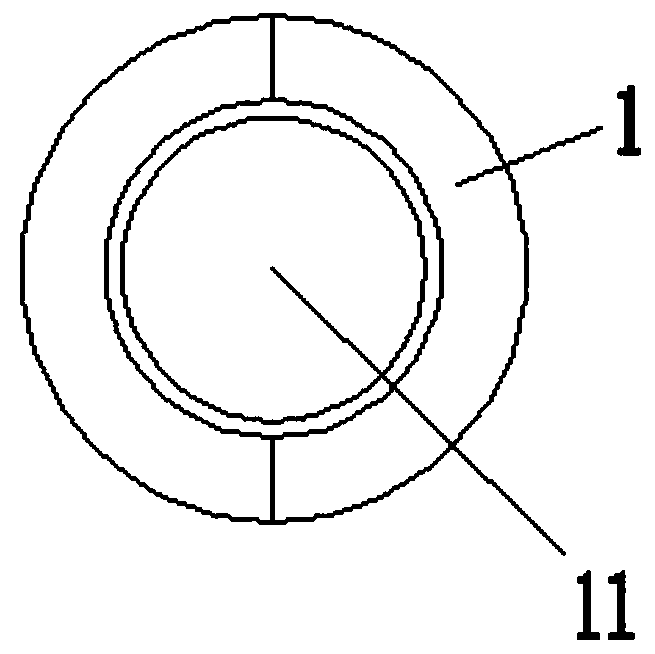

[0044] see Figure 1 to Figure 3 , the figure shows a prefabricated suspended ceiling leveling installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the leveling base 1 A connection hole 11 is arranged inside, and the inner wall of the connection hole 11 is provided with an internal thread; Through the setting of the above structure and the setting of the connection hole 11, it is convenient to connect with the central connecting piece 2; the conical structure design can improve the connection strength between the leveling base 1 and the wall top 3.

Embodiment 3

[0046] see Figure 1 to Figure 7 , the figure shows a prefabricated suspended ceiling leveling installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: central connector 2 Including connecting screw 21 and connecting plate 22, connecting plate 22 is arranged on the bottom of connecting screw 21, connecting screw 21 is threadedly connected with connecting hole 11; connecting screw 21 and connecting plate 22 are perpendicular, connecting plate 22 is parallel to wall top 3 ; Through the setting of the above structure, the connecting screw 21 is threadedly connected with the connecting hole 11, which is convenient for adjusting the height of the central connecting piece 2; the setting of the connecting plate 22 is convenient for clamping with the keel 4, which is convenient for installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com