Awning eave surface yellow bar

A canopy and cover technology is applied in the field of light box identification, which can solve the problems of inconvenient maintenance, long construction period, and high energy consumption of light boxes, and achieve the effects of convenient replacement and maintenance, short construction period and good energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The utility model will be further described below in conjunction with the accompanying drawings and specific embodiments.

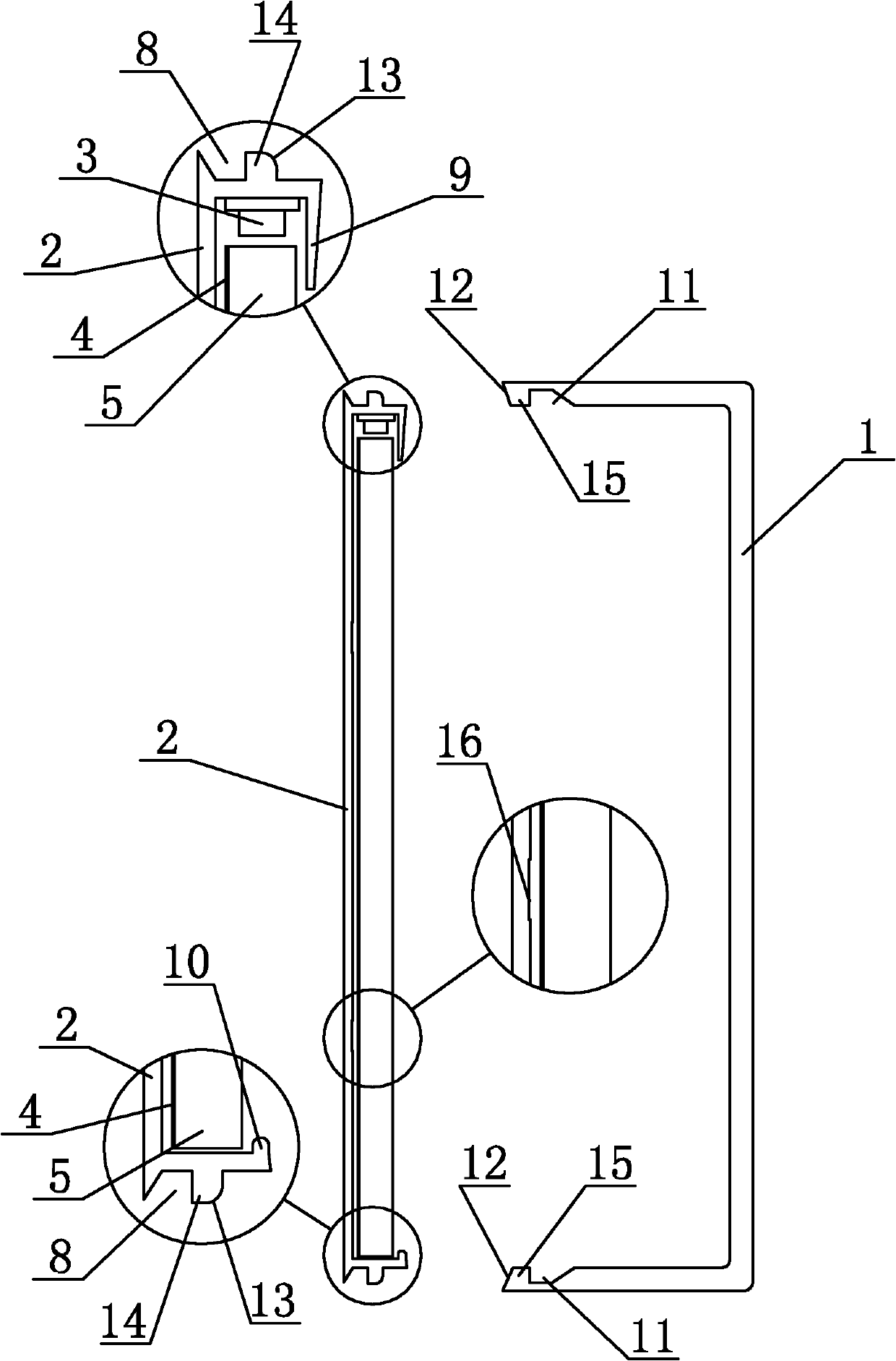

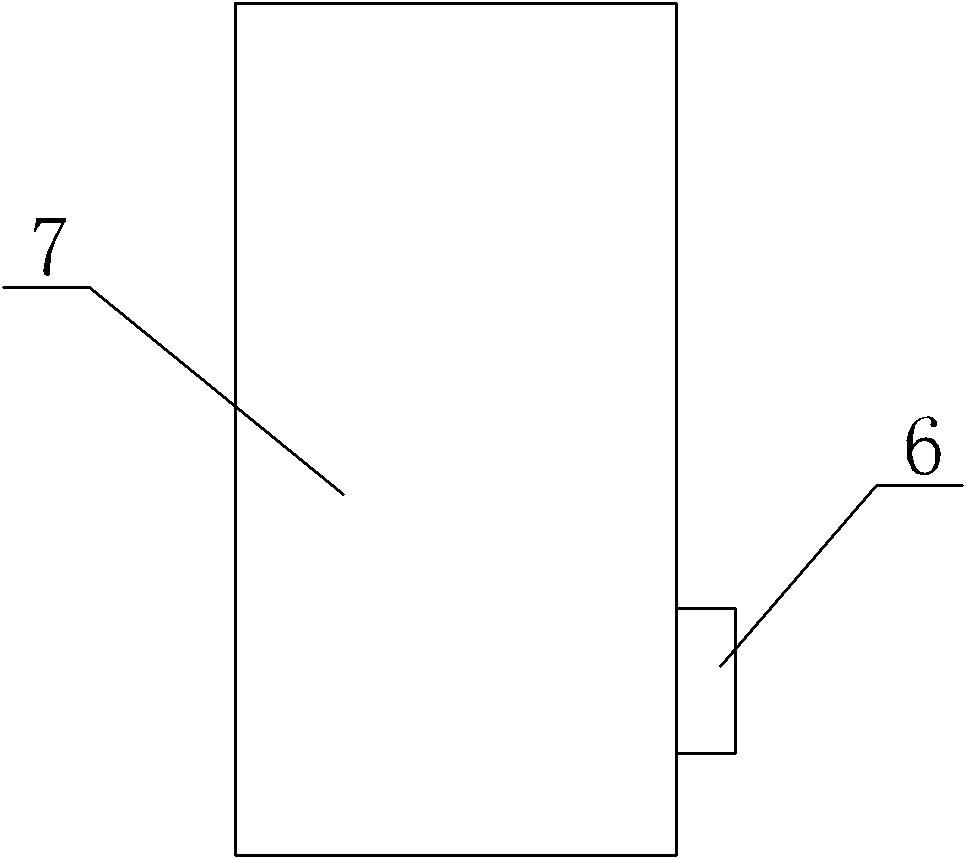

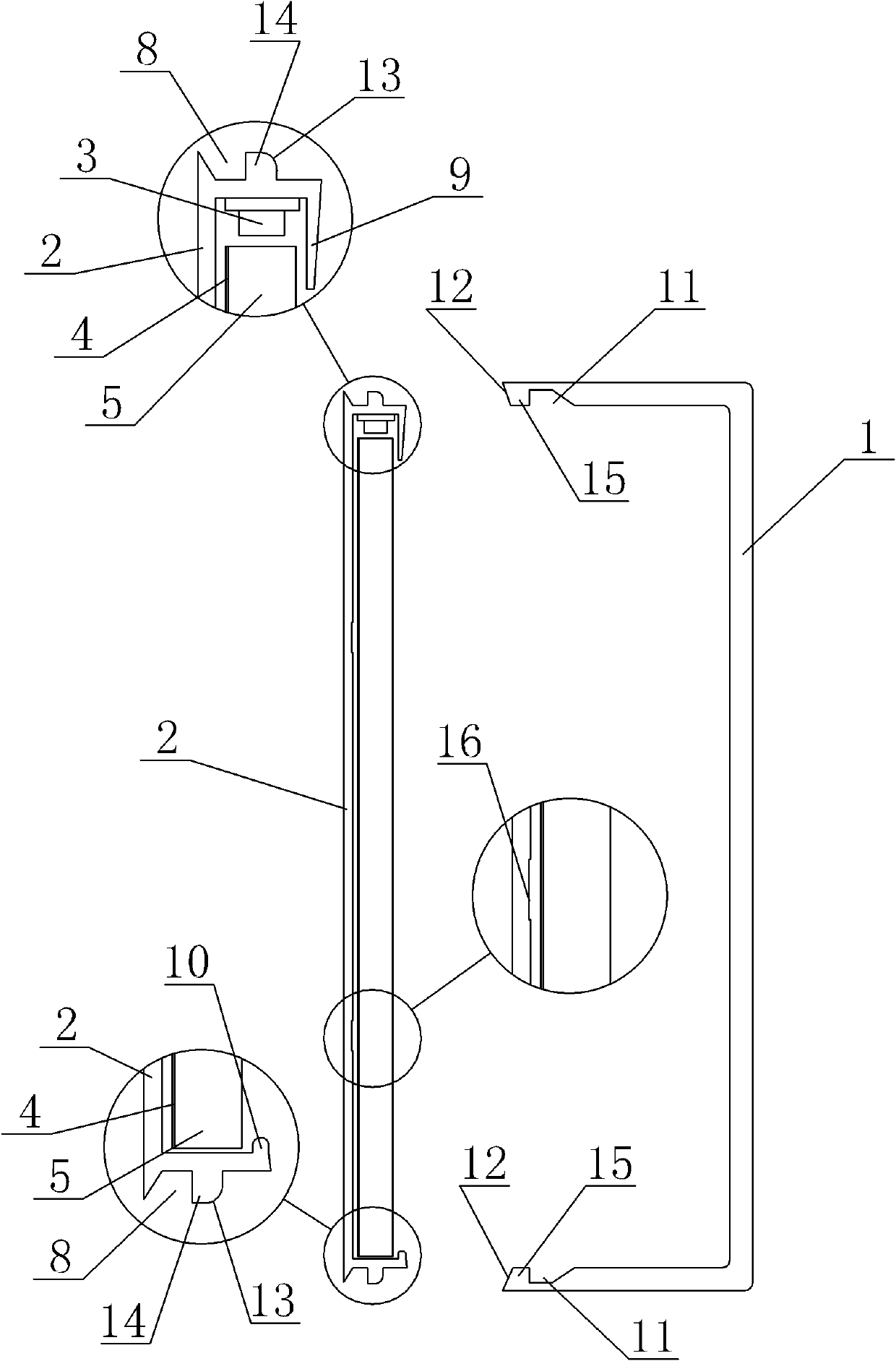

[0015] Such as figure 1 As shown, the yellow bar on the eaves of the canopy includes a light-transmitting outer cover 1 and a back plate 2 with a light source. The cross-section of the light-transmitting outer cover 1 is U-shaped. The bottom edge is clamped, the end faces of the two bent transverse parts on the light-transmitting outer cover 1 are oblique guide surfaces 12, and the outside of the bent transverse part at the rear part of the oblique guide surface is provided with a trapezoidal cross-section limit groove 11, and the oblique guide surface and the limit The transverse portion between the bit slots forms the clamping end 15 .

[0016] The bottom edges of the upper and lower sides of the backboard 2 are bent inwardly to form installation grooves. The bottom edge of one side of the backboard has a long folded edge 9, and the bottom edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com