System and method for implementing a virtual metrology advanced process control platform

An advanced process control and virtual measurement technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problem of not being able to obtain wafers one by one

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention relates to advanced process control of integrated circuit manufacturing, in particular to a system and method for setting a virtual measurement advanced process control platform. In the present invention, the specific embodiments are only used as examples to teach the broader inventive concepts, and those skilled in the art can easily apply the techniques disclosed in the present invention to other methods and systems. Moreover, the systems and methods discussed in the present invention include some well-known structures and / or steps, which are only used as a general level discussion for detailed discussion because they are well known. Furthermore, for the convenience of description, the repeated element labels in the illustrations are only examples, and the repetition of the multiple element labels does not imply any necessary combination of features or steps.

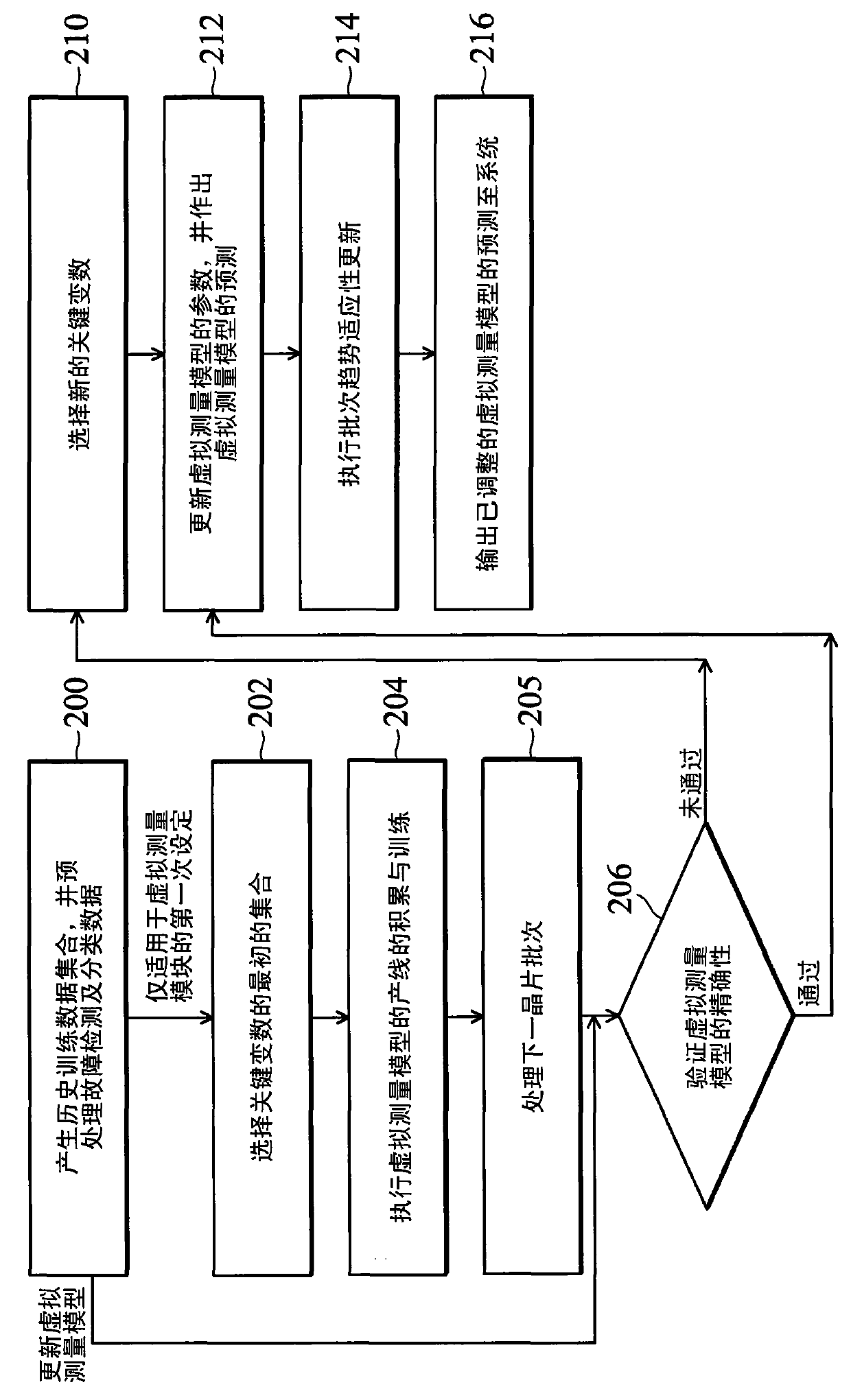

[0026] Figure 1A Known virtual measuring principles for individual processes. The module 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com