Device and method for aligning the position of plate-shaped parts

A part and plate shape technology, applied in positioning devices, machine tool parts, feeding devices, etc., can solve problems such as impossible parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

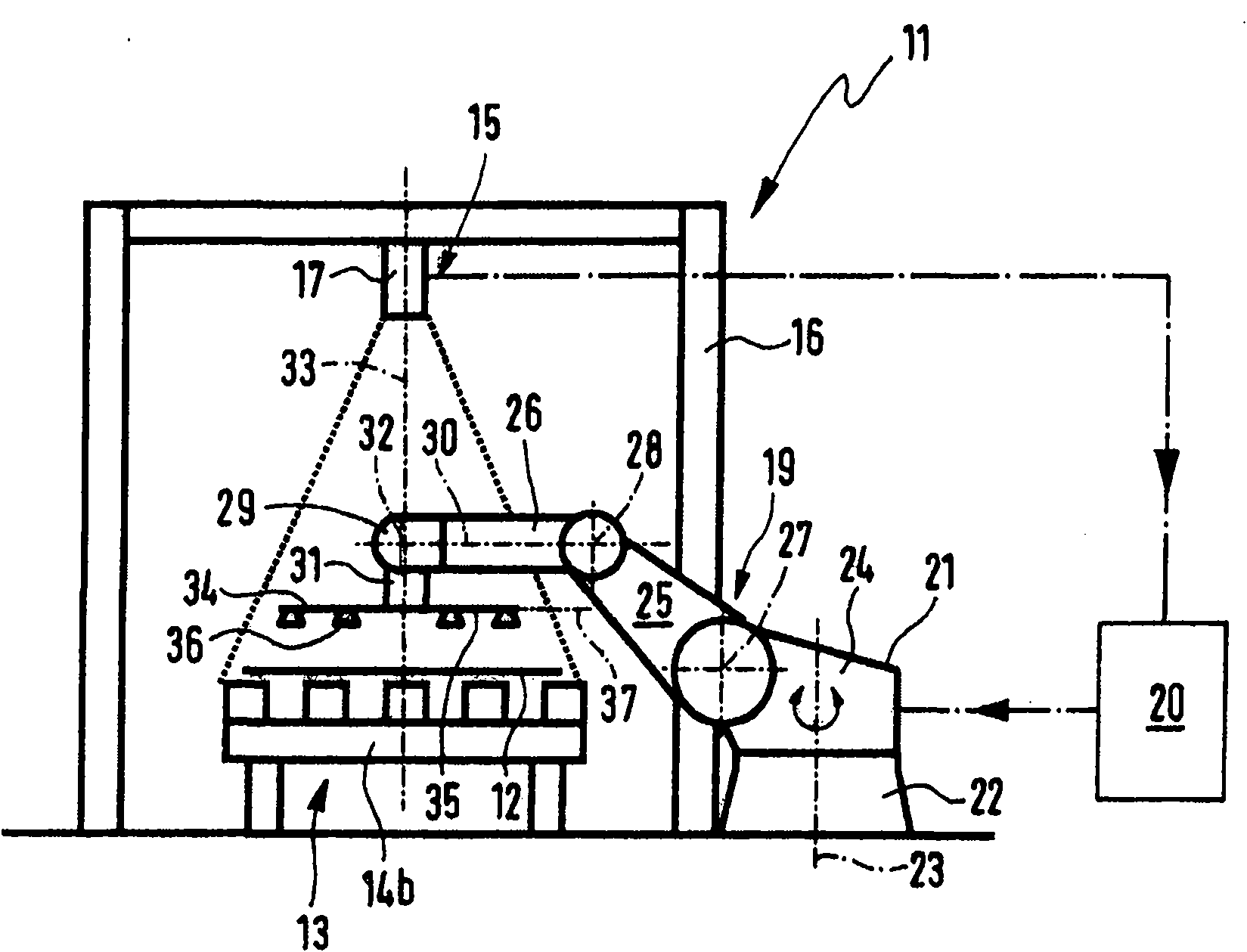

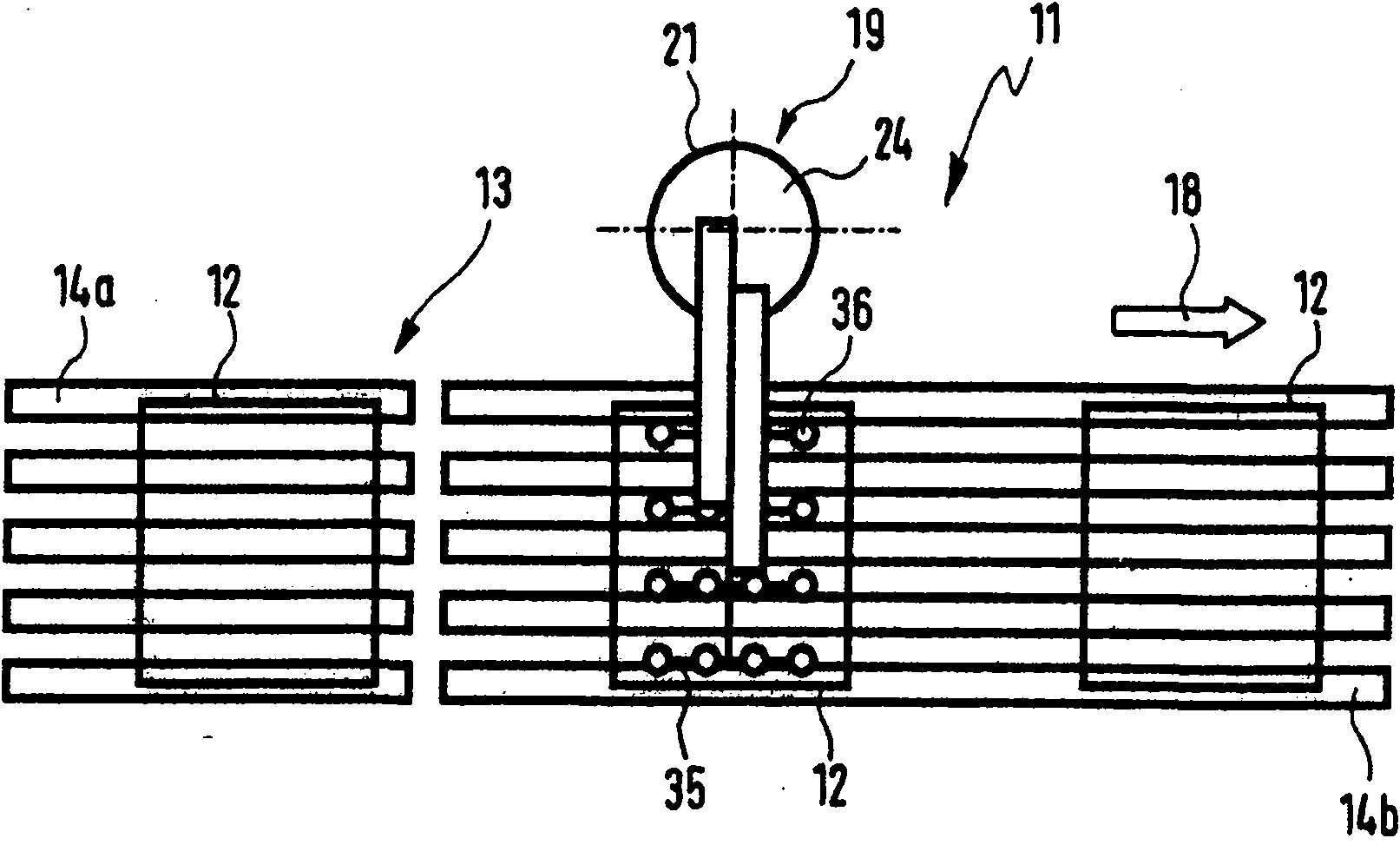

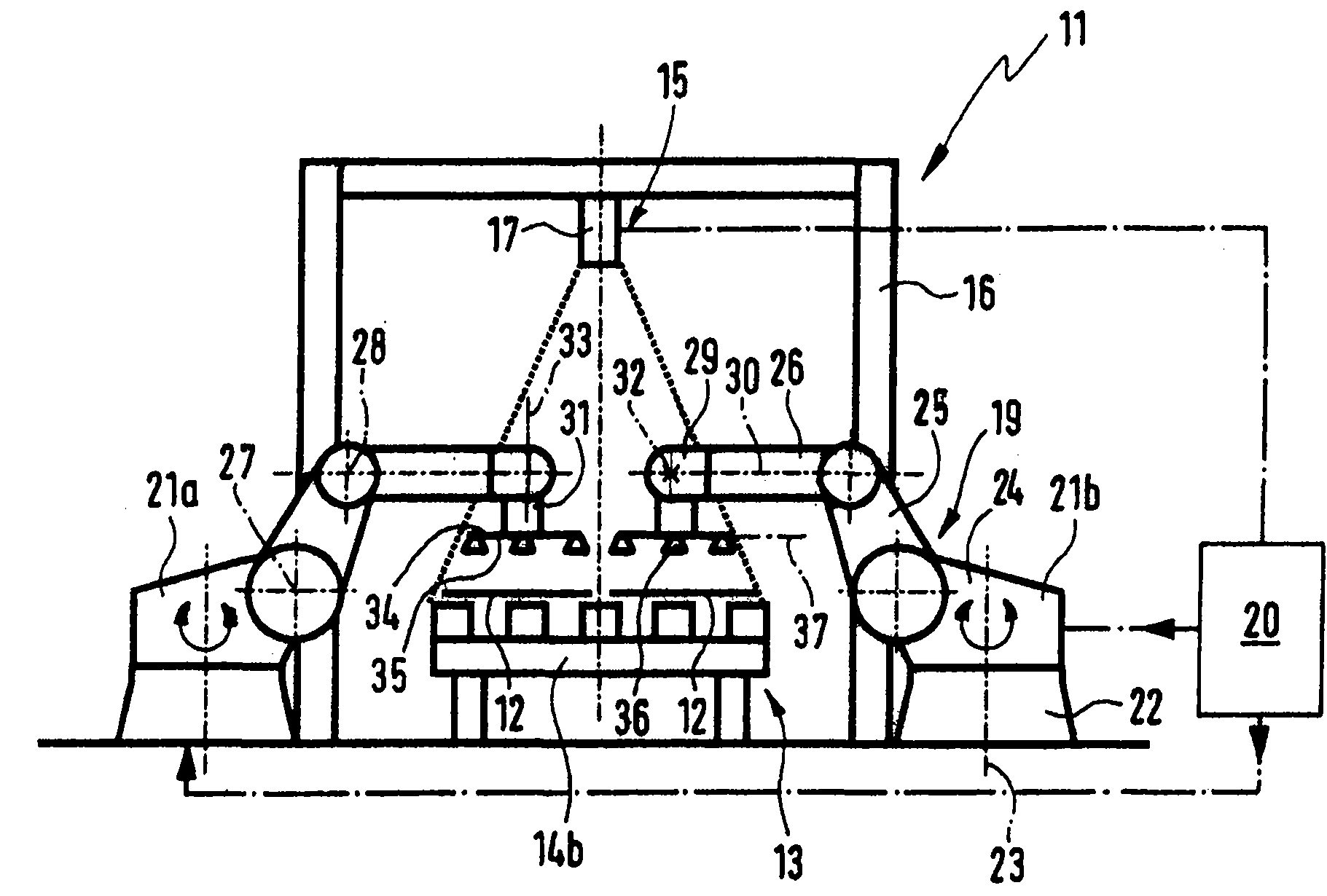

[0034] figure 1 with figure 2 A preferred embodiment of a device 11 according to the invention for positional positioning of a plate-shaped part 12 is shown. In this regard, the plate-shaped part 12 is a sheet metal blank, eg a body panel which has not yet been formed. The device for positioning, hereafter referred to simply as the positioning device 11, is part of a stamping line in which the plate-shaped part 12 finally reaches a metal forming press in which the plate-shaped part 12 is formed .

[0035] The position-locating device 11 comprises a continuous conveying device 13 for conveying the plate-shaped parts 12 . The continuous conveying device 13 comprises a plurality of corresponding conveyor belts 14a, 14b on which the plate-shaped parts 12 which have been previously depalletized or separated by a depalletizing device (not shown) are conveyed.

[0036] The position locating device 11 also includes an optical measuring device 15, suitably placed above one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com