Automatic production method and device for small packages of salted vegetables

The technology of a production method and production equipment is applied in the field of automatic production of pickled vegetables in small packages, which can solve the problems of difficult control of desalination time, poor degree of automation, and inaccurate measurement control, so as to avoid hidden dangers of microbial index rise and improve food quality. The effect of hygienic quality and precise measurement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

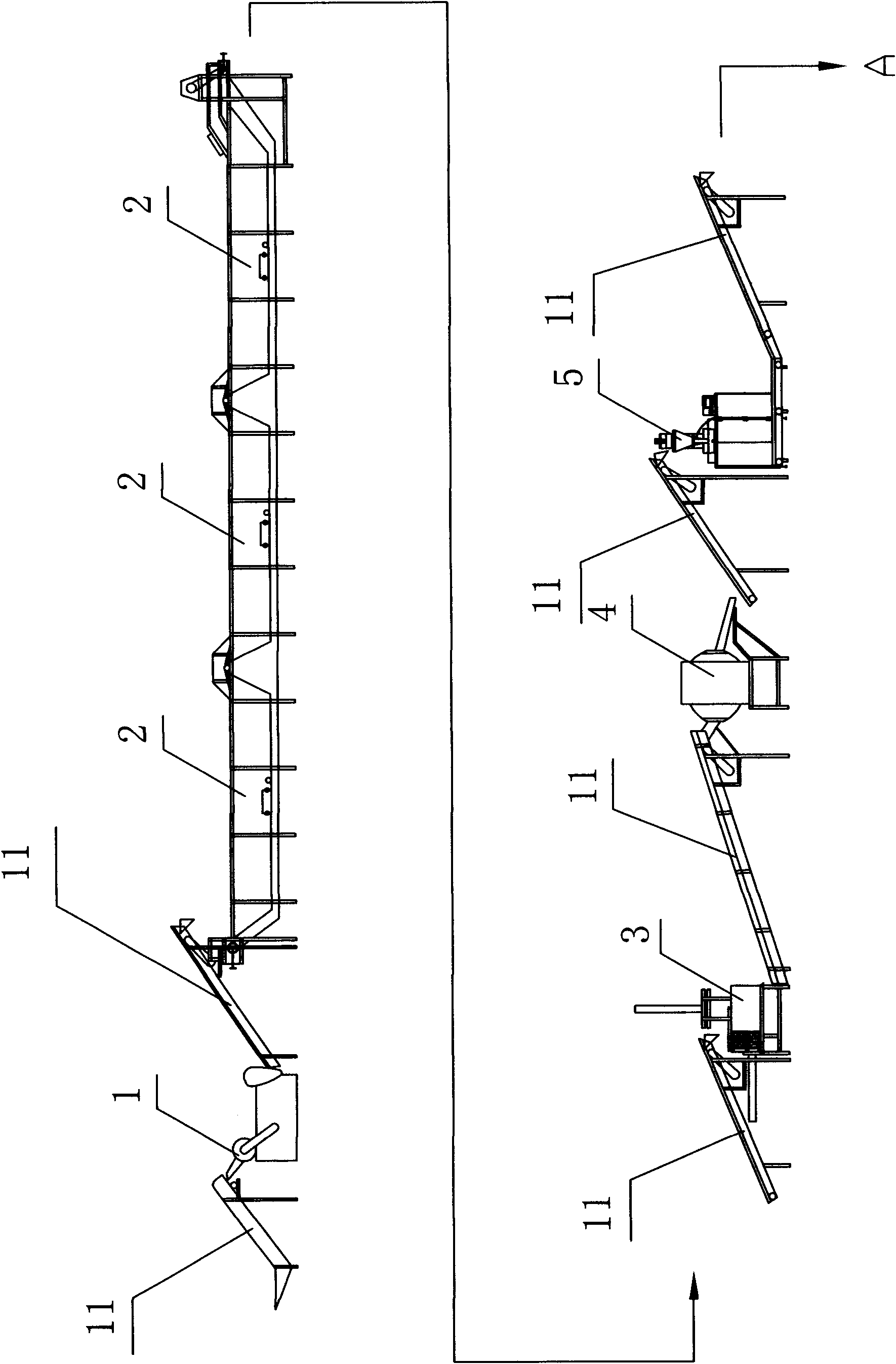

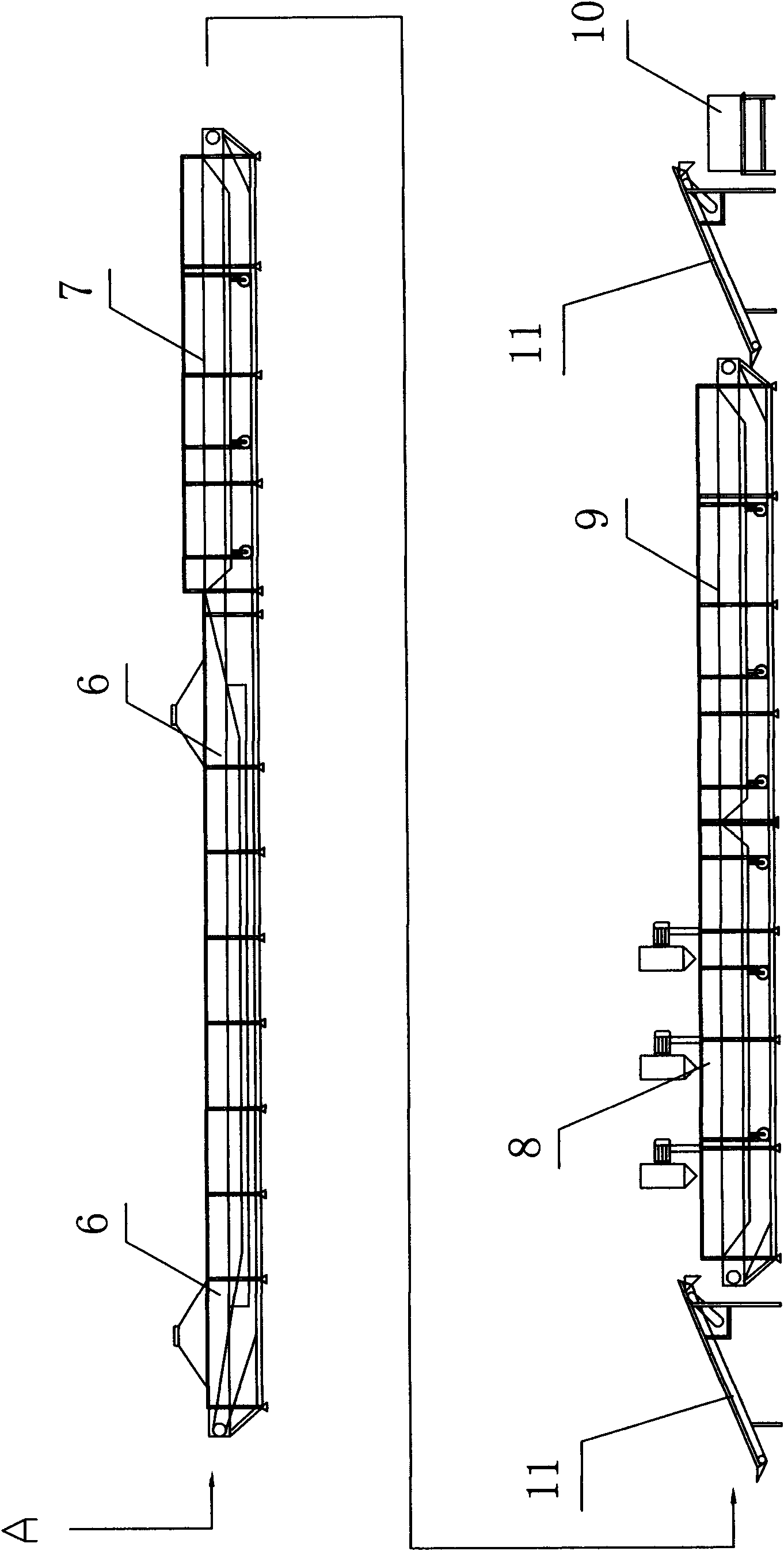

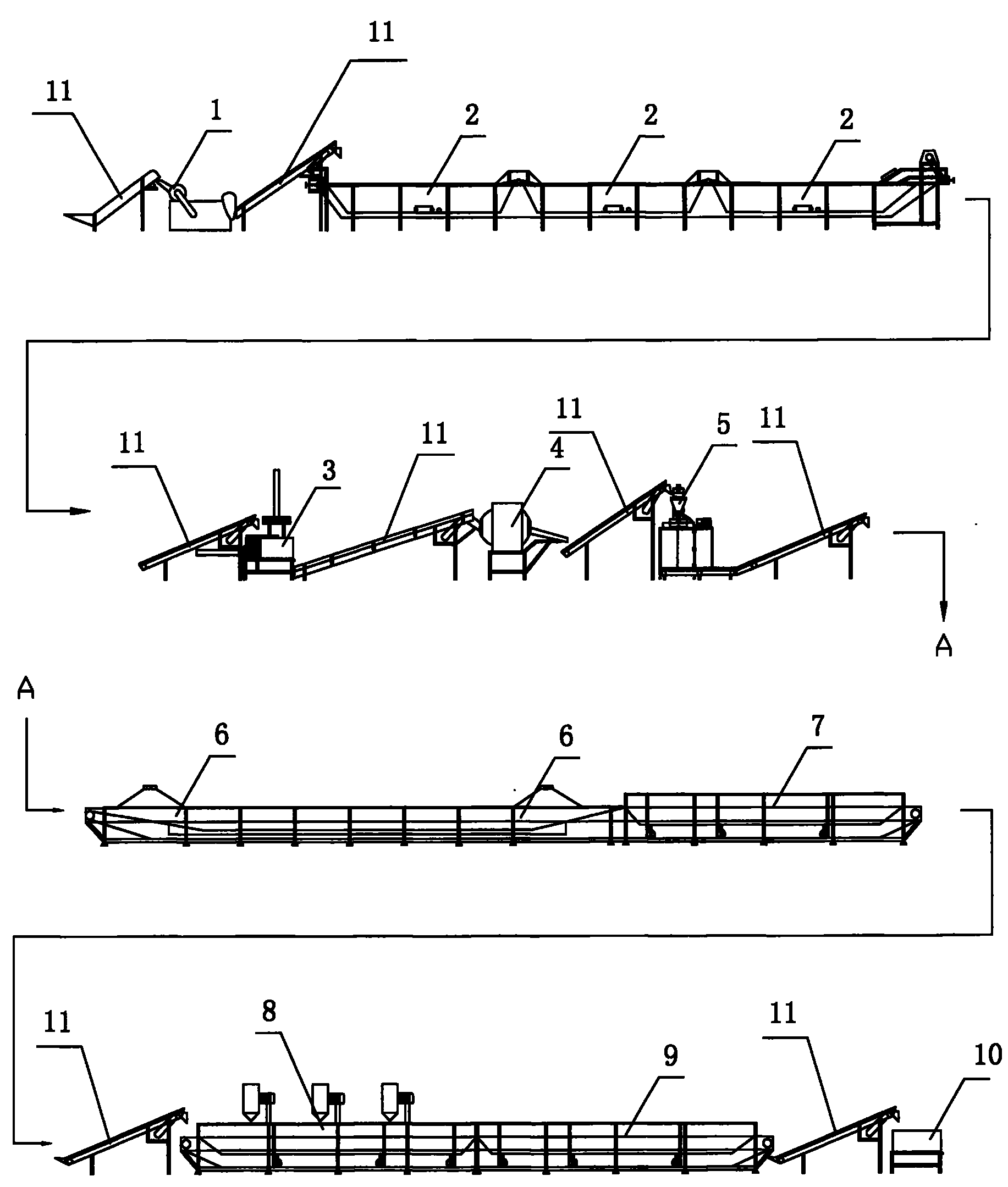

[0035] An automatic production method and equipment for pickled vegetables in small packages, comprising the following steps:

[0036] (1) Cutting: cut pickled vegetable raw materials into slices, shreds, strips or blocks. After cutting, the finely divided waste can be separated by vibration, and the raw materials that meet the standards can be sent to the next step;

[0037] (2) Desalination: The desalination process is carried out through the control of water capacity and the combination of time. The cleaning is carried out continuously in the cleaning water tank which is divided into three sections. The actual water content of the first cleaning water tank is 1200 kg. For 900 kg / 15 minutes, the time for pickle raw materials to pass through each cleaning tank is 6.5 minutes, and 25% of salt can be removed through each cleaning tank, and the salinity is reduced from 14% to 10.05%; Cleaning the water tank removes 25% of the salt, and the salinity drops to 7.875%; after cleanin...

Embodiment 2

[0048] Packing becomes the small package of every bag 90 grams, and sterilization adopts pasteurization, carries out in closed hot water tank, and its used time is: 15 minutes, remaining with embodiment 1.

Embodiment 3

[0050] Be packed into the small package of every bag of 180 grams, pasteurization is adopted, and carry out in closed hot water tank, and its used time is: 16 minutes, all the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com