Control method under dynamic soft reduction and determining method of reduction interval

A control method and a technology for determining the method, applied in the field of slab continuous casting technology, can solve the problems of reducing segregation, inability to precisely control the roll reduction, inability to control the reduction interval, etc., and achieve the effect of avoiding damage to the casting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0027] During the slab continuous casting process, a large amount of solutes with low melting point are enriched between the dendrites due to the effect of selective crystallization during the solidification process. The residual liquid enriched with impurities between the dendrites flows to the center and fills it, resulting in defects such as center segregation and center porosity of the slab. Based on this, it is considered that it is more appropriate to implement dynamic soft reduction within a distance close to the solidification end, rather than performing dynamic soft reduction at a position far away from the solidification end.

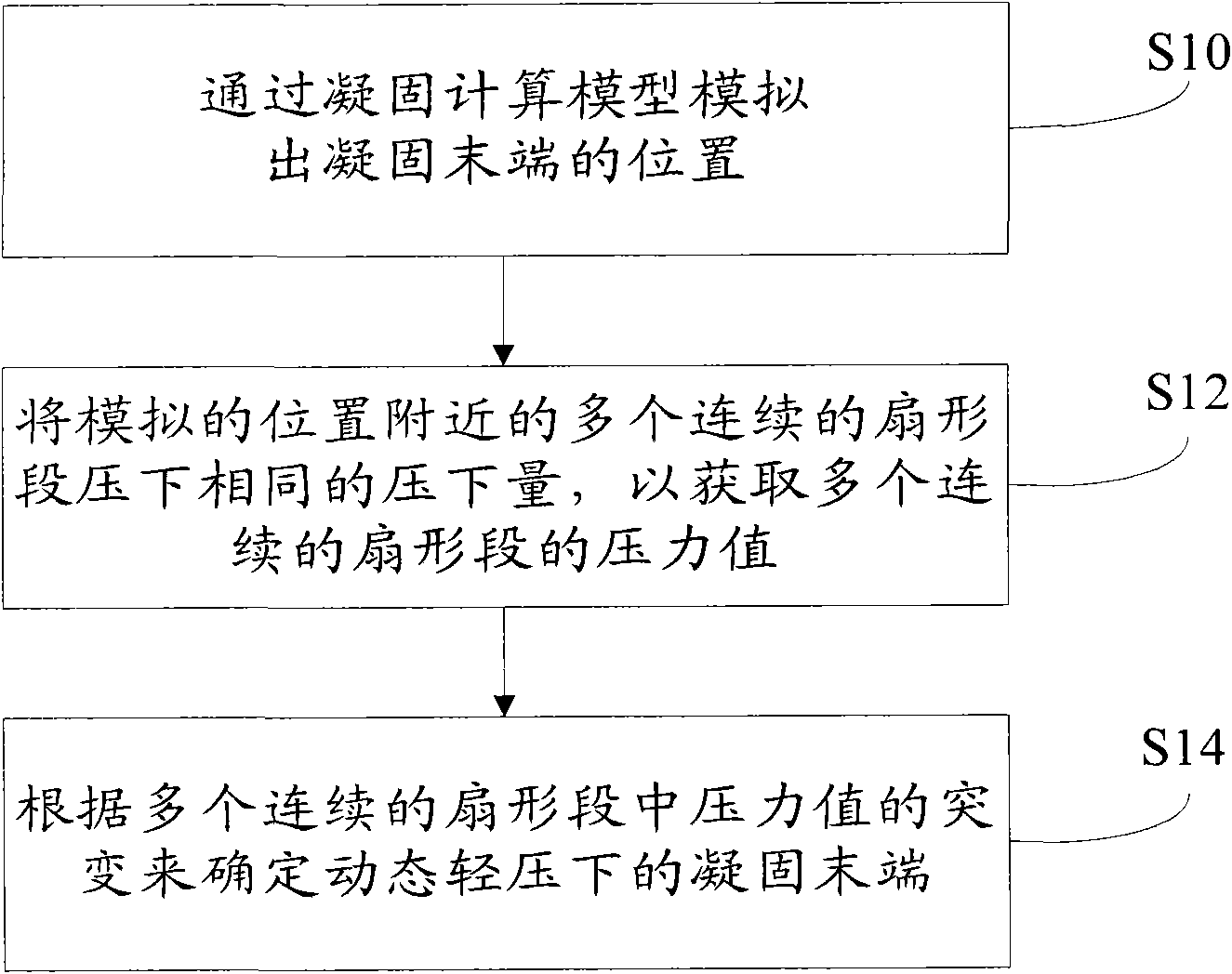

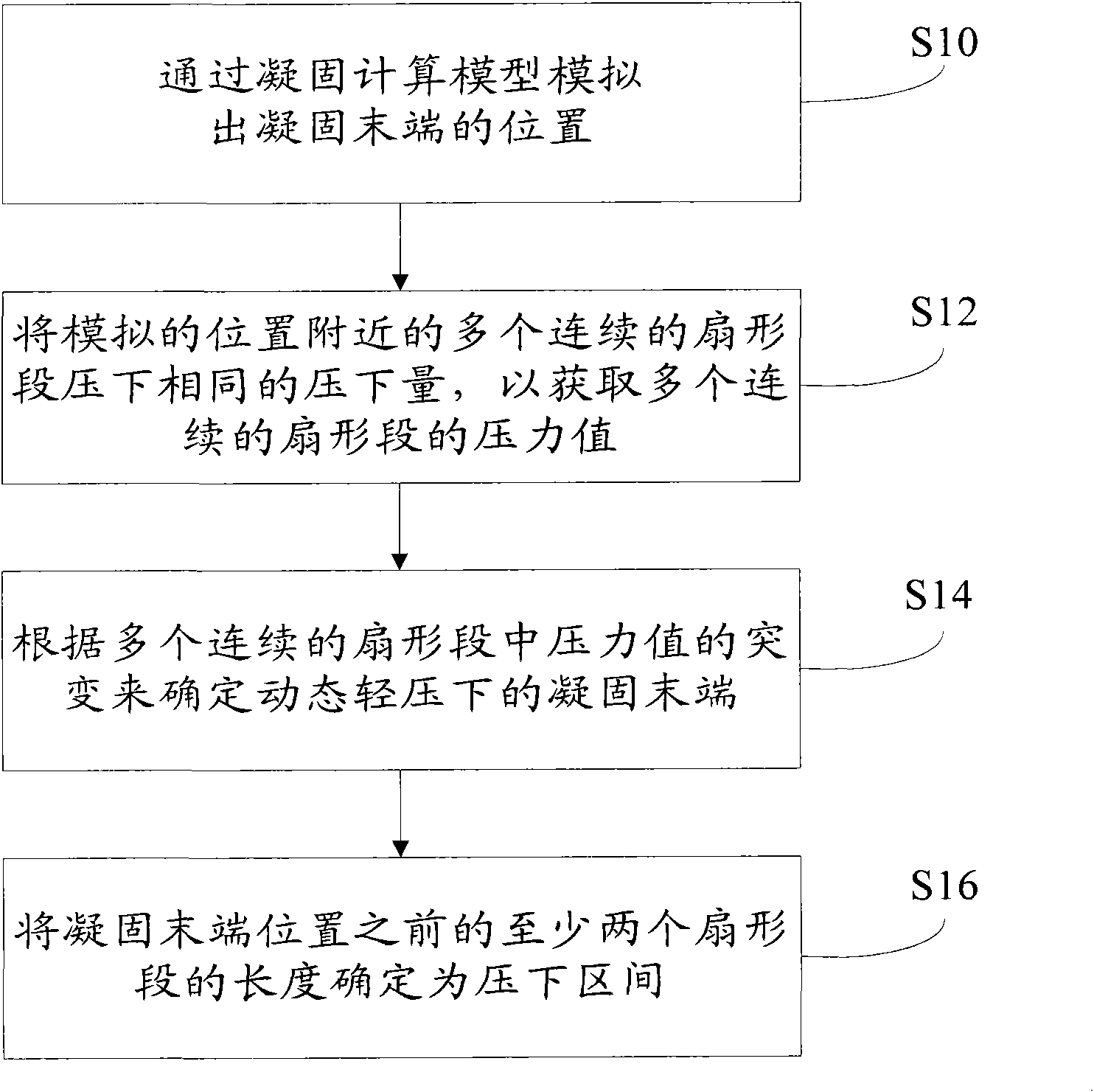

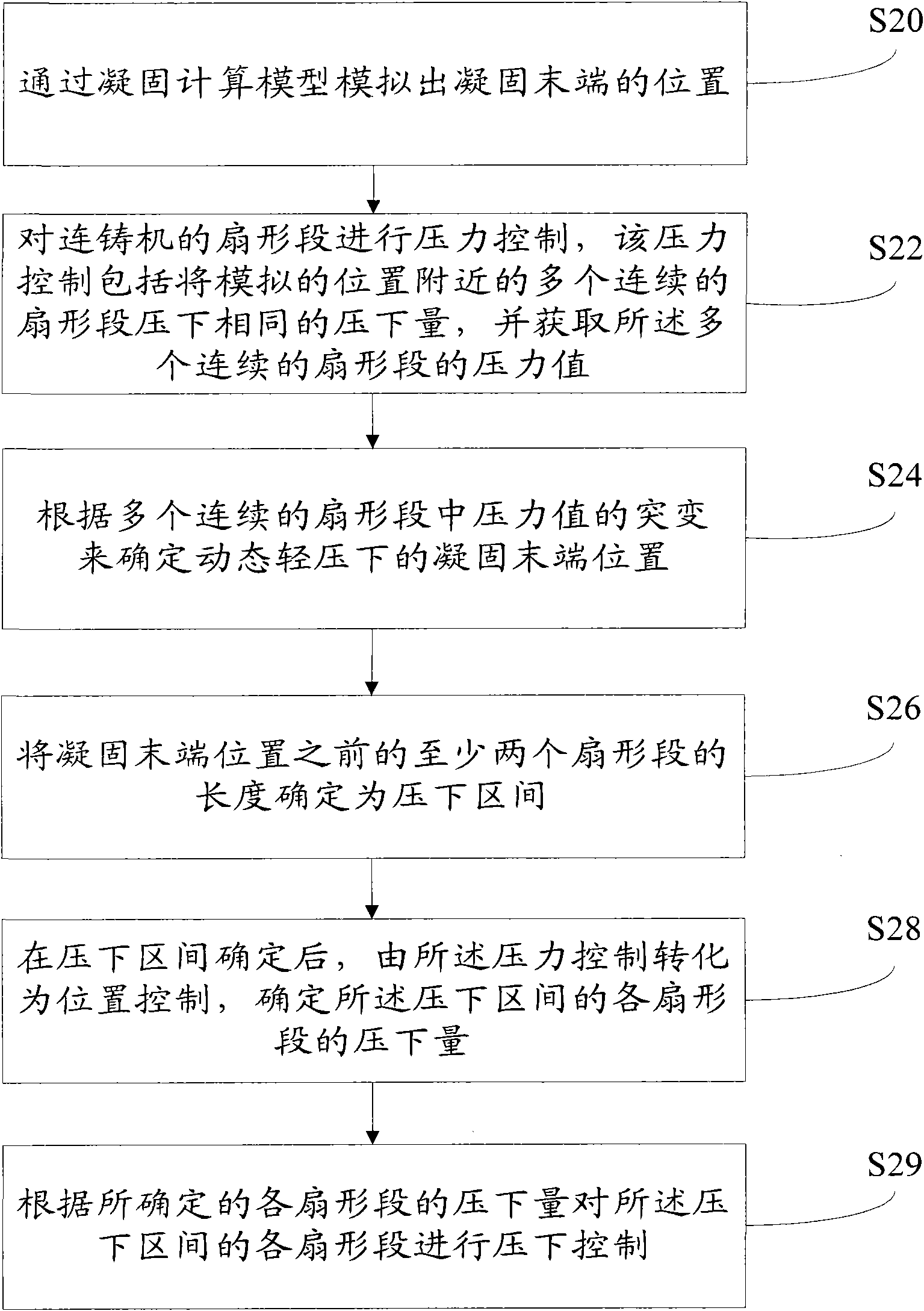

[0028] figure 1 A flow chart of the method for determining the light solidification end of continuous casting dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com