Method for preparing silver nano granules by reducing plant extract

A plant extract, silver nanoparticle technology, applied in the field of plant extract reduction to prepare silver nanoparticles, can solve the problems of slow reaction, need several hours to dozens of hours, etc., achieve high dispersibility and stability, improve The reduction reaction rate and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

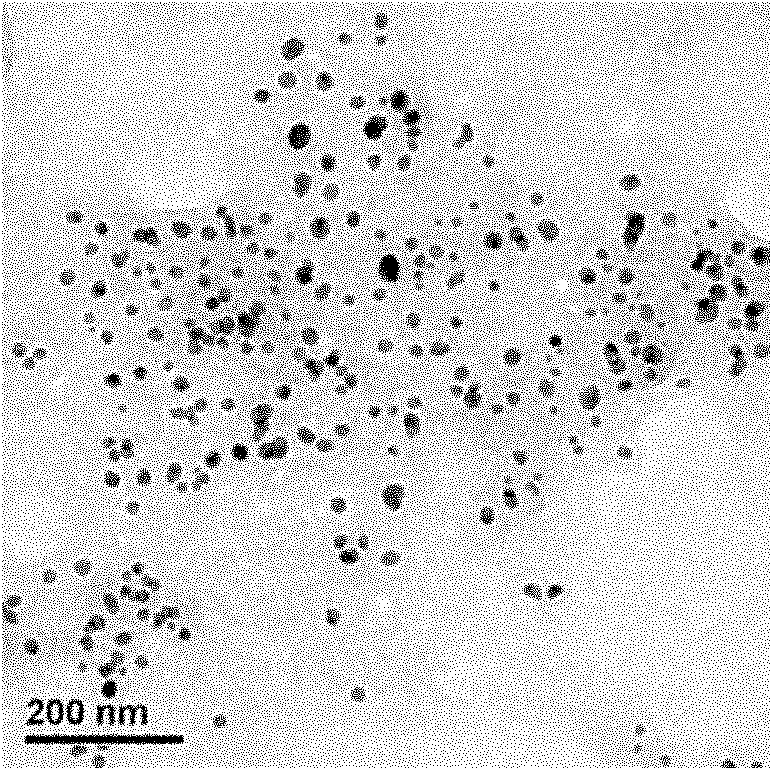

[0016] Cinnamomum camphora leaves were dried in a blast drying oven at 60°C and then pulverized. Weigh 0.25g of Cinnamomum camphora leaf powder and add it into 50mL of deionized water, leaching at room temperature for 6h, filter and separate and remove leaf powder residue to obtain Cinnamomum camphora leaf extract, add 25mL of extract to a 50mL Erlenmeyer flask, and add 0.5mol / L silver ammonia solution 50μL, after shaking well, microwave continuous treatment at 420W power for 15s. Observing the reaction product with a transmission electron microscope (TEM), the obtained silver nanoparticles are all nearly spherical particles, most of the particle diameters are distributed in the range of 8-35nm, and the average particle diameter is 19.4nm.

Embodiment 2

[0018] Cinnamomum camphora leaves were dried in a blast drying oven at 60°C and then pulverized. Weigh 1g of Cinnamomum camphora leaf powder and add it to 50mL deionized water, leaching at room temperature for 6h, filter and separate and remove leaf powder residue to obtain Cinnamomum camphora leaf extract, add 25mL extract to a 50mL Erlenmeyer flask, and add 0.5mol / 100 μL of L silver ammonia solution, shake well and microwave treatment, under 700W power, with 5s as a treatment cycle, intermittent microwave treatment for three cycles. Observing the reaction product with a transmission electron microscope (TEM), the obtained silver nanoparticles are all nearly spherical particles, most of the particle diameters are distributed in the range of 9-27nm, and the average particle diameter is 18.3nm.

Embodiment 3

[0020] Cinnamomum camphora leaves were dried in a blast drying oven at 60°C and then pulverized. Weigh 2.5g of Cinnamomum camphora leaf powder and add it into 50mL deionized water, leaching at room temperature for 6h, filter and separate and remove the leaf powder residue to obtain Cinnamomum camphora leaf extract, add 25mL of extract to a 50mL Erlenmeyer flask, and add 0.5mol / L silver ammonia solution 250μL, shake well, microwave treatment, continuous treatment at 280W power for 30s. Observing the reaction product with a transmission electron microscope (TEM), the obtained silver nanoparticles are all nearly spherical particles, most of the particle diameters are distributed in the range of 11-29nm, and the average particle diameter is 18.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap