Keyless drill chuck

A drill chuck and hand tightening technology, applied in the mechanical field, can solve problems such as poor safety, affecting drilling quality, and affecting work efficiency, and achieve stable working performance, good self-locking effect, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

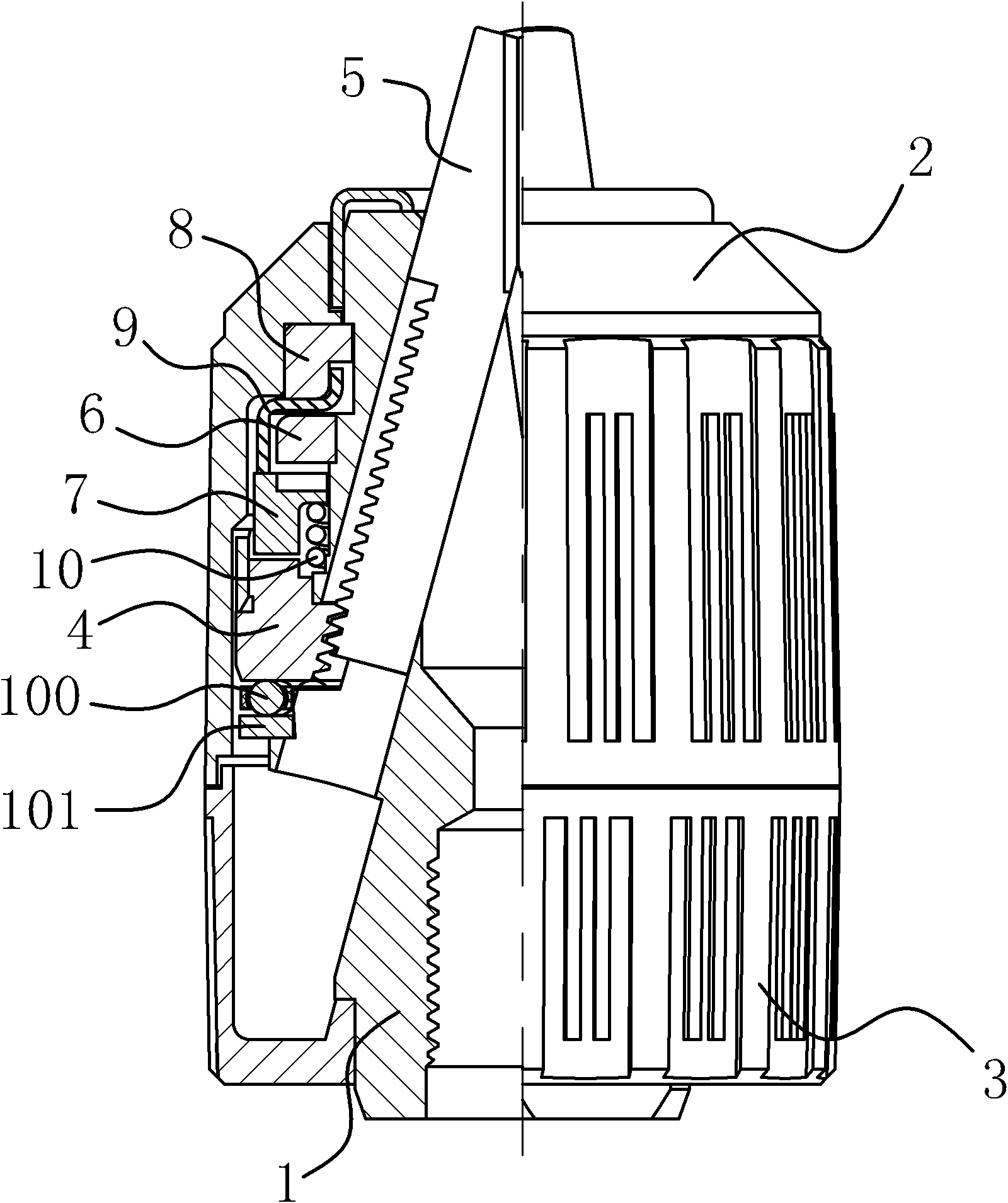

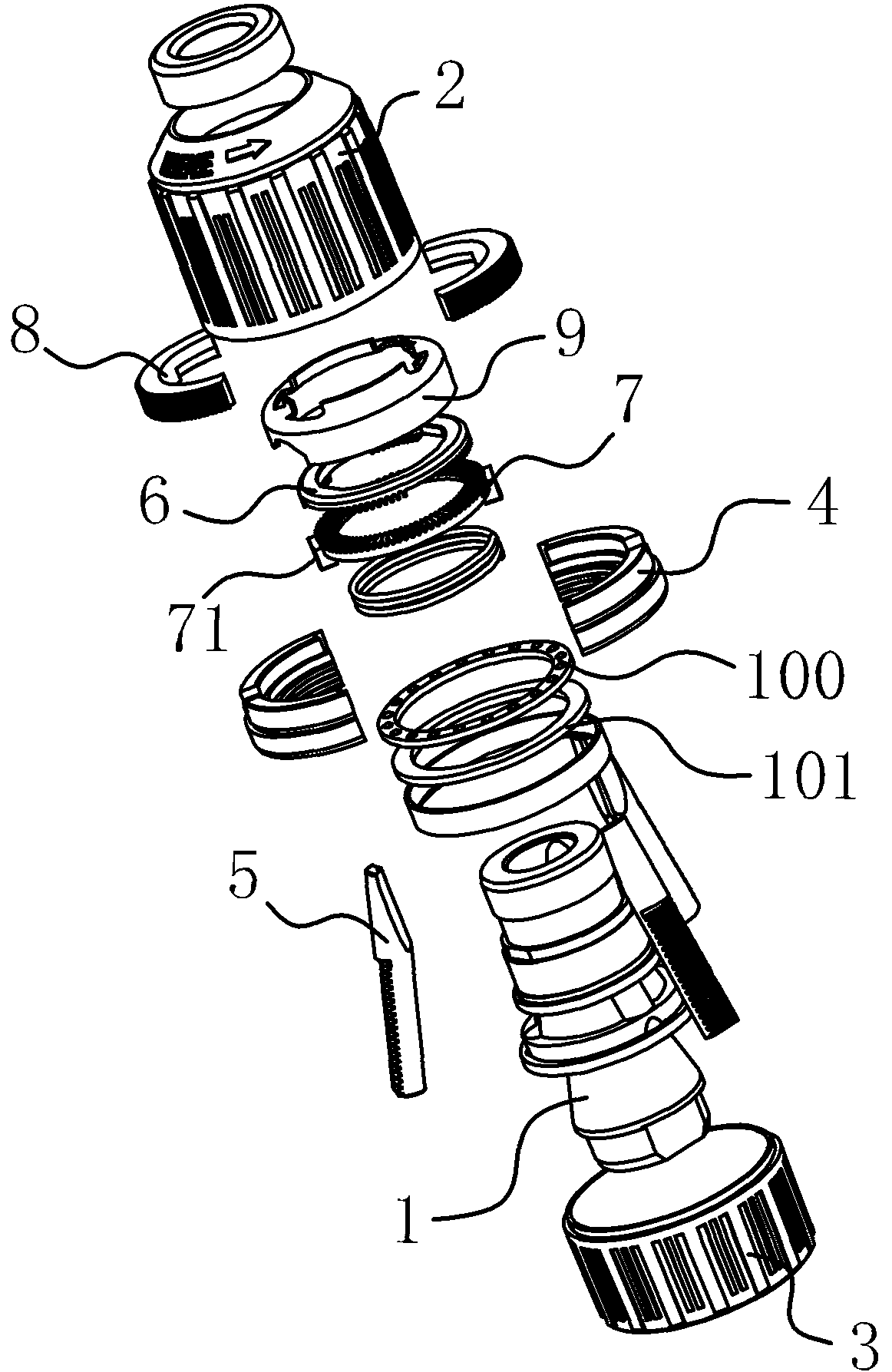

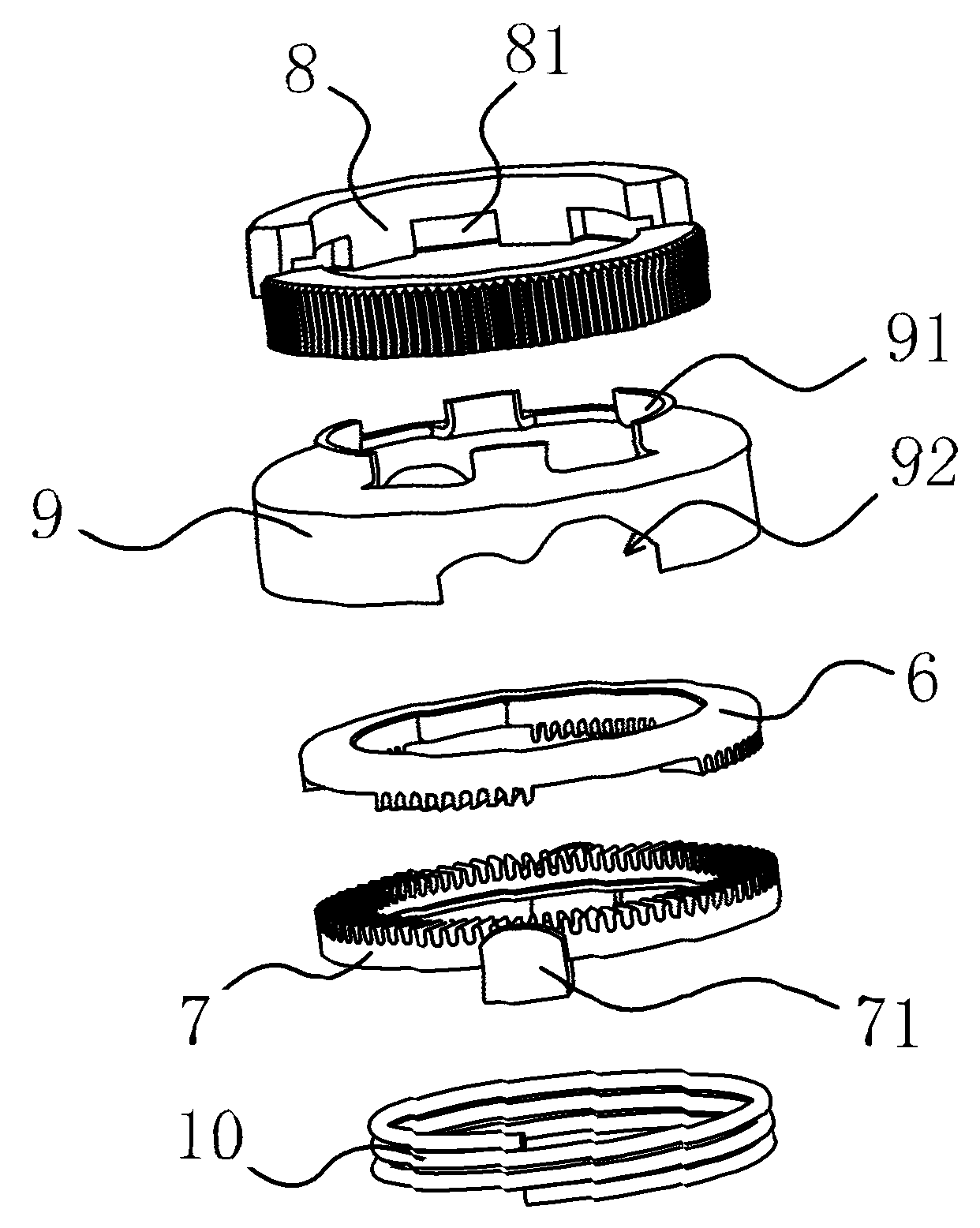

[0029] Such as figure 1 and figure 2 The hand-tight drill chuck shown includes a drill body 1 and a cylindrical front sleeve 2 and a rear sleeve 3 which are sequentially placed on the outside of the drill body 1. The drill body 1 is provided with three equally divided oblique holes, and the oblique holes are respectively Clamping jaws 5 are provided with external threads on their outer sides. A cavity is formed between the front cover 2, the rear cover 3 and the drill body 1, and a ring-shaped spiral ring 4 with a groove on the top is provided in the cavity, and the above-mentioned spiral ring 4 and the clamping jaw 5 are connected by threads. An adjustment structure is also arranged on the upper part of the spiral ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com