Method for improving transverse impact toughness of seamless steel tube

A technology of seamless steel pipe and transverse impact, which is applied to furnace types, furnaces, heat treatment furnaces, etc., and can solve problems such as collapse, scrapping, and production reduction of the entire well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

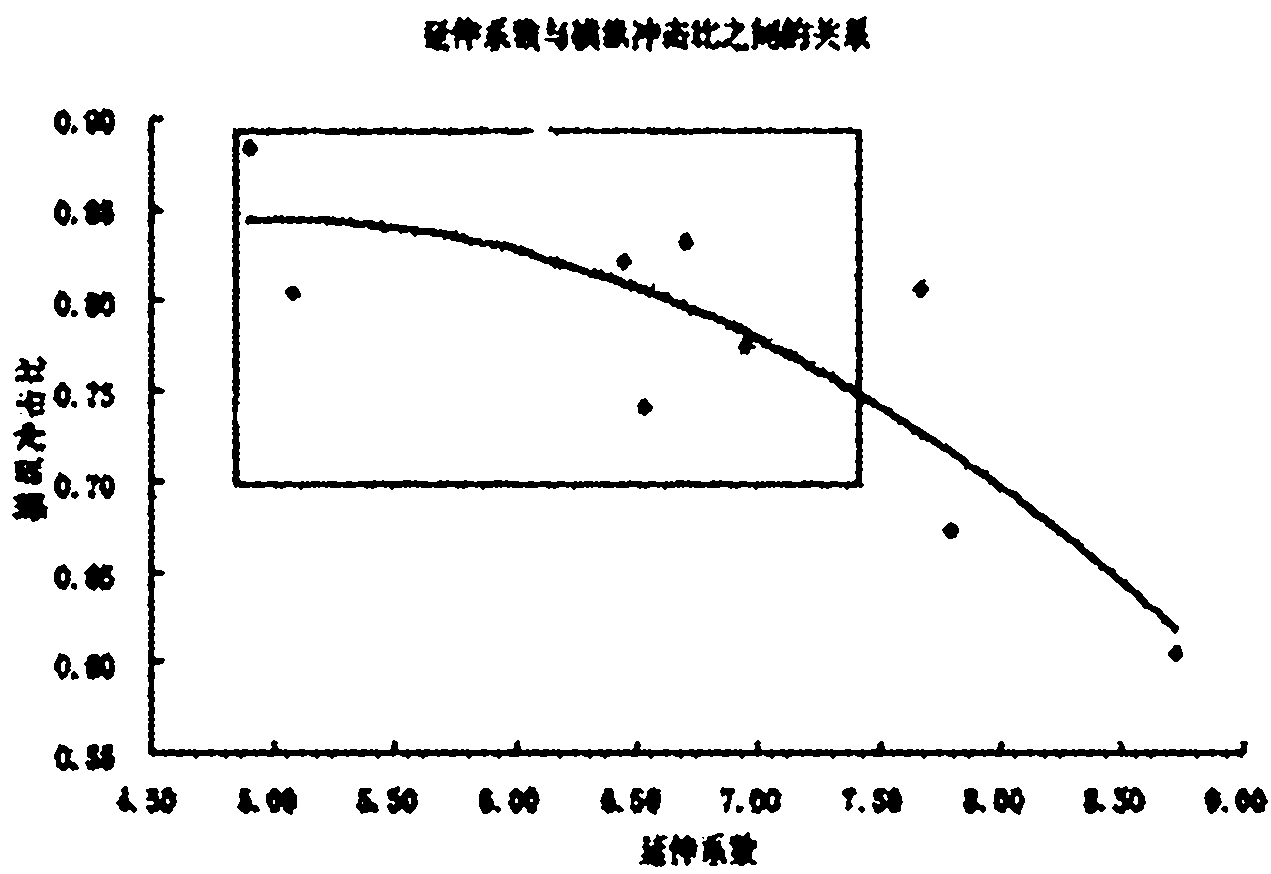

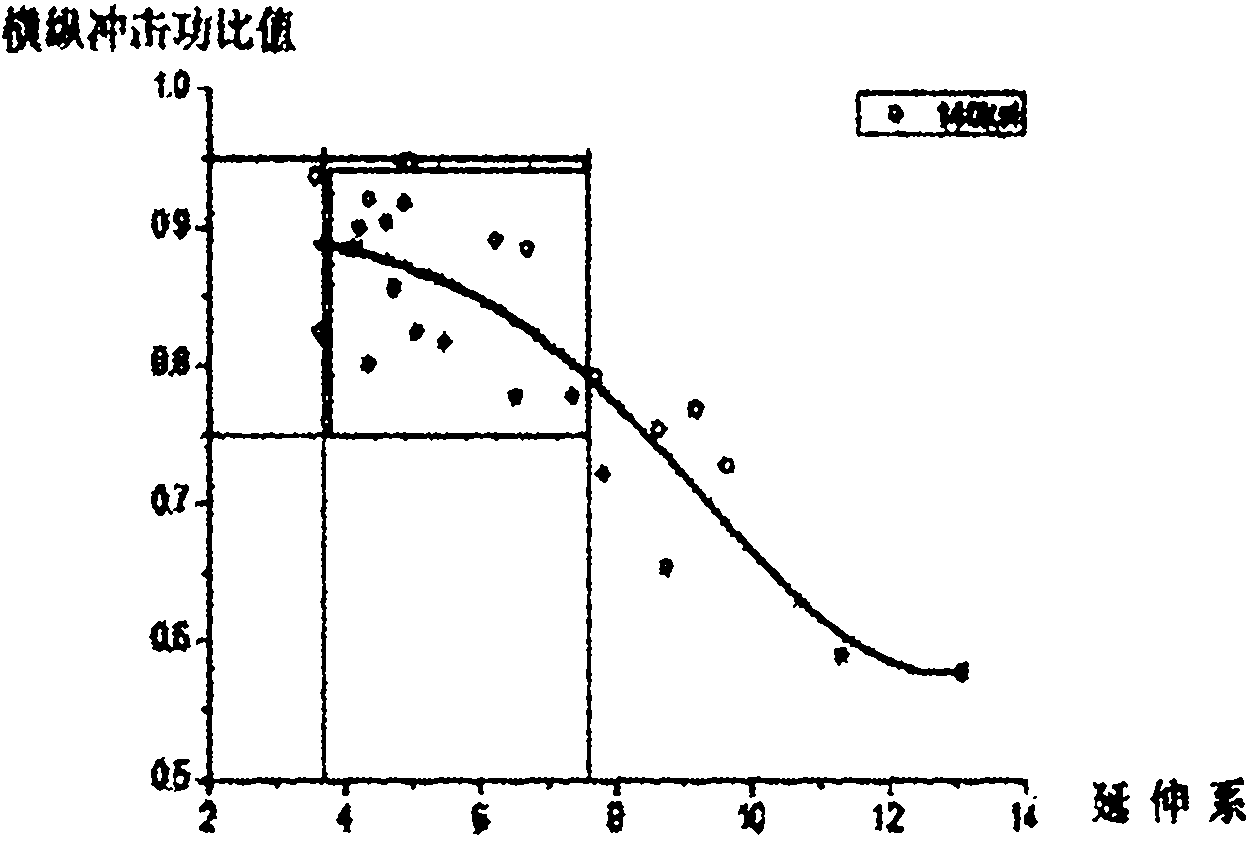

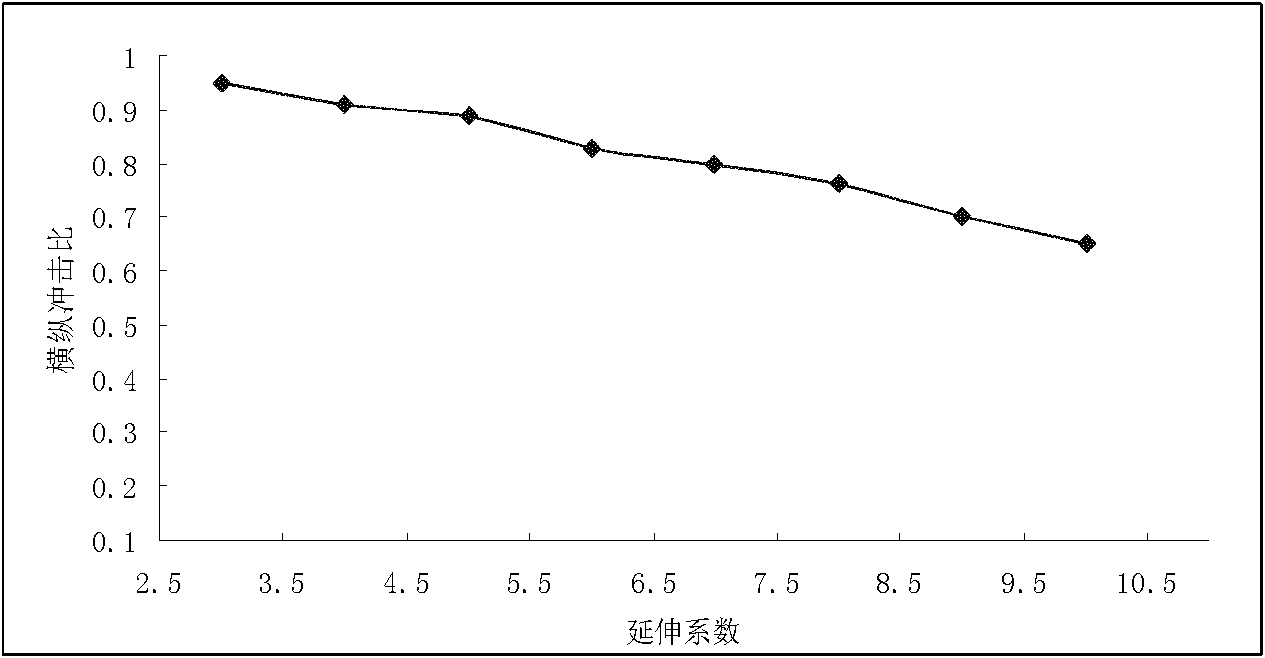

[0039] The method for improving the transverse impact toughness of seamless steel pipes of the present invention will be described with reference to the accompanying drawings and examples.

[0040] The method for improving the transverse impact toughness of seamless steel pipes of the present invention is applicable to seamless steel pipes for oil casings, oil pipes, drill pipes, screw drilling tools, and gas cylinder pipes that have high requirements for transverse impact energy and withstand high pressure. The weight ratio of the constituent elements of the seamless steel pipe is C: 0.22-0.50%, Si: ≤0.50%, Mn: 0.60-1.90%, Cr: ≤1.50%, Mo: ≤1.10%, Al: 0.015-0.060%, Ni <1.00%, V: <0.15%, P≤0.015%, S≤0.005%, O≤0.004%, N≤0.013%, H≤0.0004%, and the rest is iron; the method includes the following steps:

[0041] ① Tube billet smelting and continuous casting:

[0042] Oil casing materials that meet API SPEC 5CT standards are smelted and refined, and then continuously cast into contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lateral impact energy | aaaaa | aaaaa |

| Lateral impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap