Calibrating device for tilt angle sensor

A technology of tilt sensor and calibration device, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of the static calibration operation of the tilt sensor, such as large limitations, low work efficiency, and poor practicability, and achieve the convenience of replacing the sensor , Simple structure, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

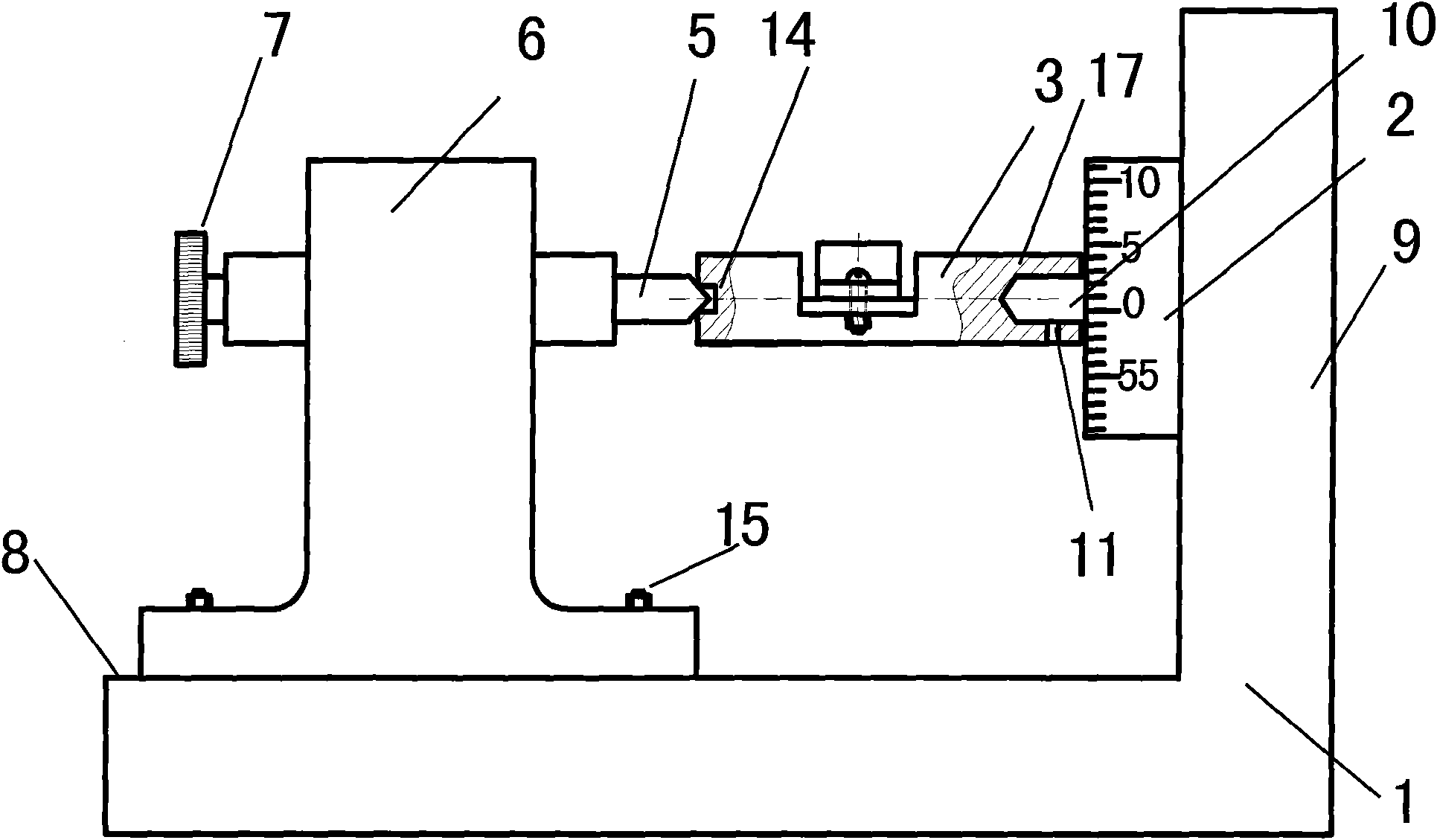

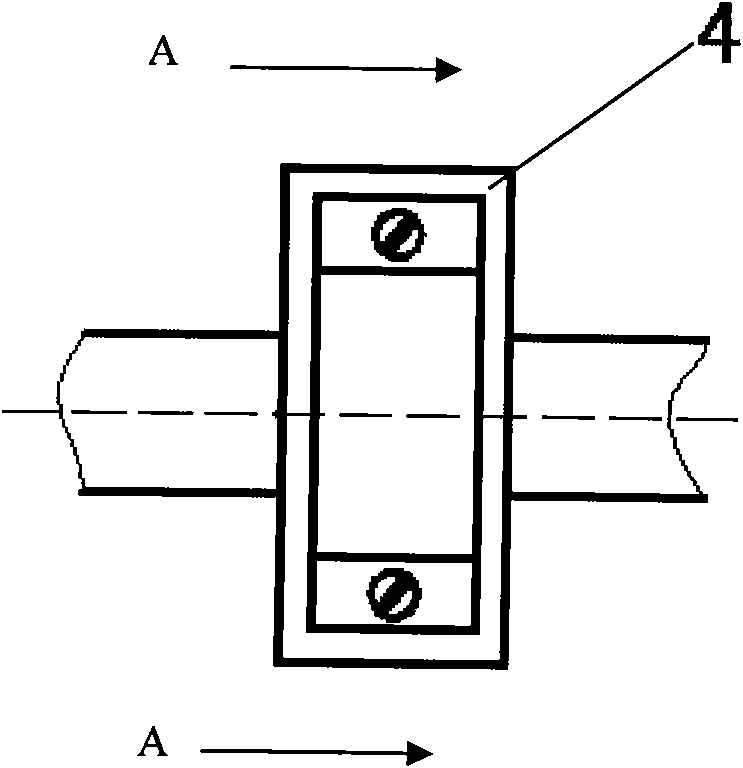

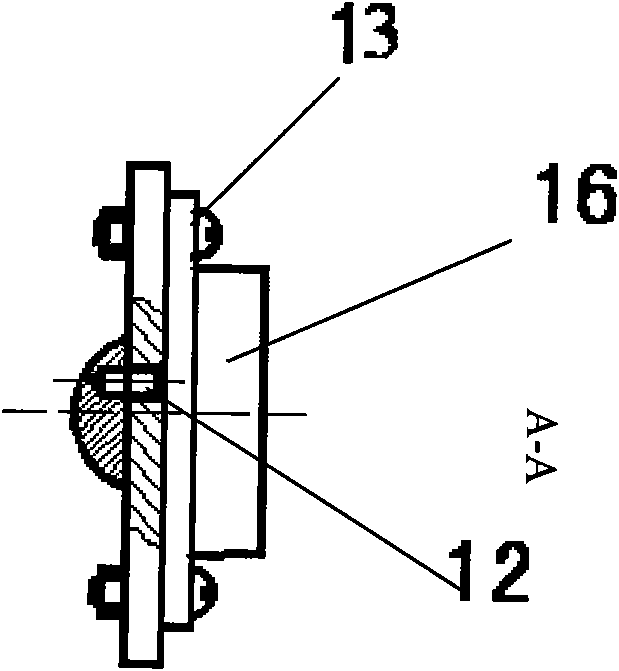

[0016] see figure 1 , which is a structural schematic diagram of a preferred embodiment of the static calibration device for the inclination sensor of the present invention. In this embodiment, the tilt sensor calibration device includes a mounting base 1 , an optical indexing head 2 , a mounting shaft 3 , a mounting plate 4 , a tip 5 , a tip base 6 , and a tip handle 7 . Wherein, the installation base 1 includes a horizontal base 8 , a base 9 and a top base 6 perpendicular to the horizontal base 8 . The optical indexing head 2 is arranged on a base 9 with an angle scale engraved on it, and its axis is parallel to the horizontal substrate 8 . The tip base 6 is arranged on a horizontal base plate 8 , and the tip axis is parallel to the horizontal base plate 8 . The tip 5 is set on the side of the tip base 6 adjacent to the base 9 , and the tip handle 7 is set on the other side of the tip base 6 away from the optical indexing head 2 . Wherein, the optical indexing head 2 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com