Control method of coordinated movement of multiple cylinders of submersible omnibearing propeller

A coordinated movement and all-round technology, applied in the direction of control, transportation and packaging, and ships using feedback, to achieve the effects of reducing motion deviation, improving servo accuracy, and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

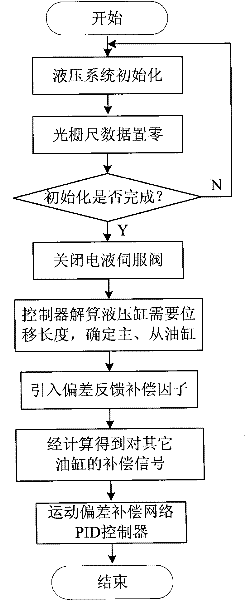

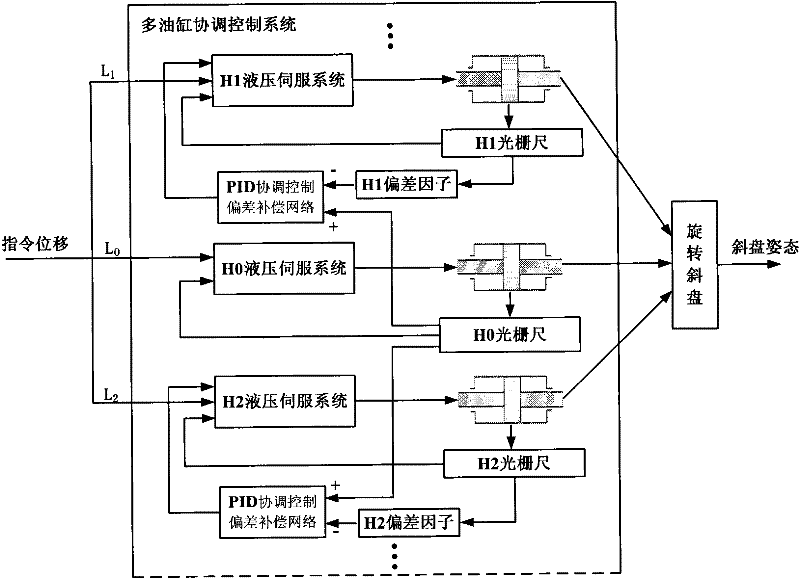

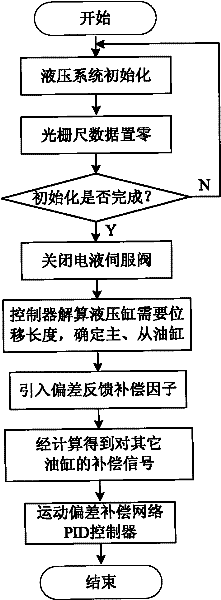

[0018] combine figure 1 , the working process of the present invention is: when the system is started, first initialize the hydraulic system, and after the initialization of the hydraulic system is completed, the controller will clear the data of the grating ruler and the system will start to work normally; According to the motion requirements, the displacement and inclination angle of the swash plate are calculated, and converted into the displacement length required by each hydraulic cylinder, and the hydraulic cylinder with the smallest moving amount is used as the reference, and it is used as the master hydraulic cylinder, and the others are slave cylinders; Rigidly connected hydraulic cylinders are constrained by satisfying the plane, so the deviation feedback compensation factor is introduced to eliminate the data inconsistency problem during deviation feedb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com