LED display screen

A technology for LED displays and circuit substrates, applied in lighting devices, light sources, instruments, etc., can solve the problems of inability to arrange components, small pixel pitch, and rising costs, eliminate graininess and dazzling feeling, and reduce the area of dark areas , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

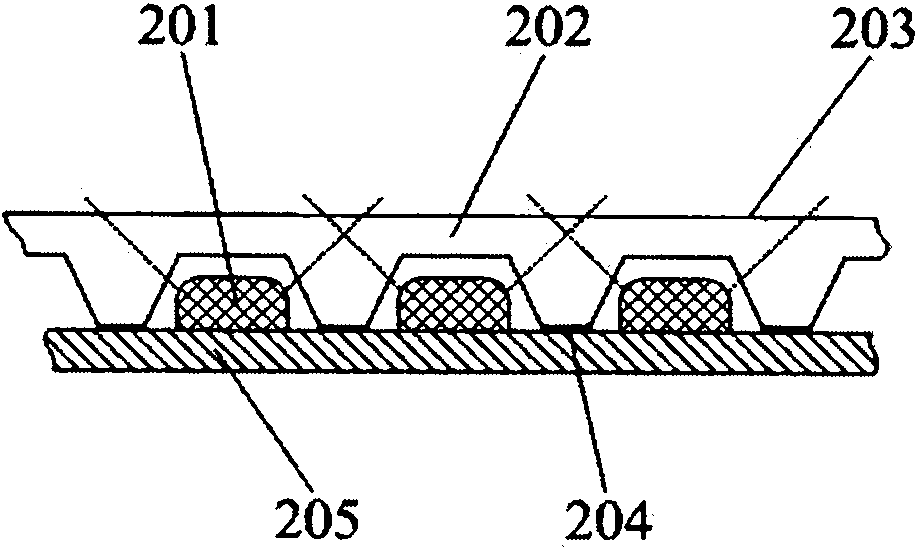

[0029] like figure 2 As shown, the LED display screen of this embodiment includes a circuit substrate 205 , several LED elements 201 distributed on the circuit substrate 205 , and a light mixing device arranged on the circuit substrate 205 .

[0030] The light mixing device is a transparent plate 202 , on one side of the transparent plate 202 there are several grooves matched with the several LED elements 201 . The groove is flared, and the shape can be a trapezoidal arc, etc., and its flared end is set toward the circuit substrate 205 , that is, the groove is upside down on the circuit substrate 205 , and there is at least one LED element 201 in the groove.

[0031] The flaring end of the groove is fixedly connected with the circuit substrate 205 through glue 204 . The transparent plate 202 can be fixed on the circuit substrate 205 by bonding, or can be fixed on the circuit substrate 205 by screws when the space is large. In this embodiment, the groove serves as a diffusio...

Embodiment approach 2

[0039] like Figure 4 As shown, the difference between the present embodiment and the first embodiment lies in the light mixing device. The light mixing device in this embodiment is a planar component 402 , and the planar component 402 is distributed with flaring holes matched with the LED elements 401 on the circuit substrate 405 . The narrow end of the flaring hole is fixedly connected with the circuit substrate 405 through glue 404 .

[0040] In addition, in order to enhance the diffusion effect, a color mixing agent can be coated in the flaring hole to make it opaque, so that the light is reflected in the cavity and superimposed with the edge light of the adjacent LED element 401, so as to achieve the purpose of light mixing. Regardless of whether the planar component 402 is made of a transparent material or a non-transparent material such as engineering plastics, a color mixing agent can be coated in the flaring hole to enhance the color mixing effect. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com