A kind of LED chip of novel structure and its manufacturing method

A technology of LED chip and new structure, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low current utilization, low LED light output efficiency, current blockage, etc., to avoid transition concentration, improve luminous efficiency, increase light elicited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

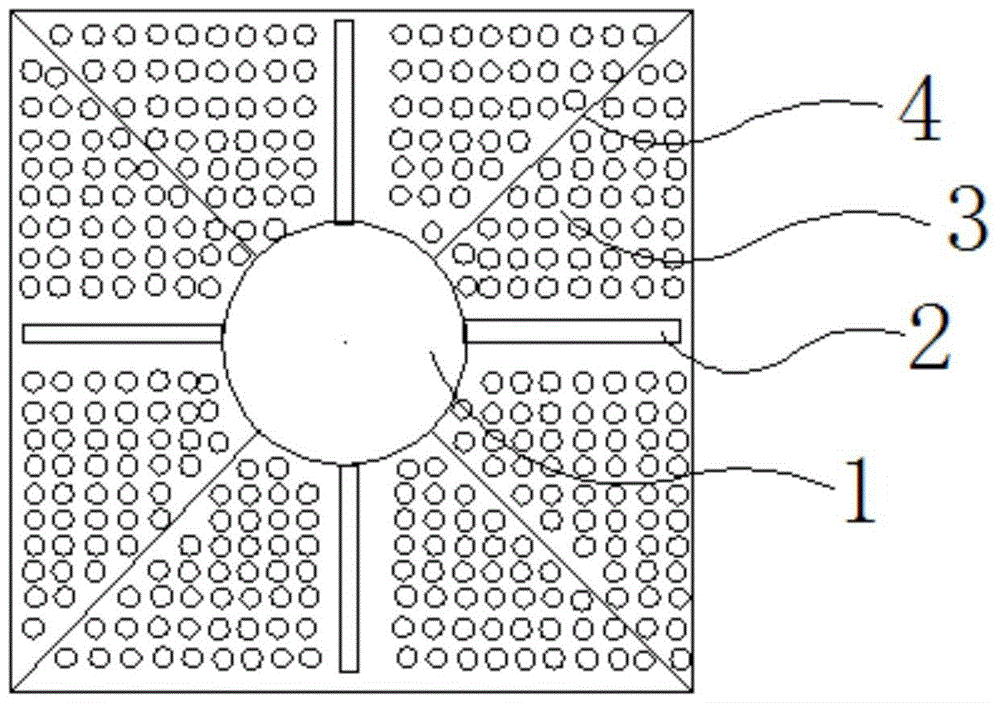

[0038] Such as figure 1 As shown, a LED chip with a new structure, the LED chip includes an N-side electrode, a substrate, an active layer, a gallium phosphide layer 3, a P-side bonding wire electrode 1, an extended electrode 2, a current blocking groove 4 and an etching hole , the current blocking groove is located on the diagonal line of the P face of the chip, and the N face electrode, the substrate, the active layer and the gallium phosphide layer 3 are sequentially arranged from bottom to top, and the gallium phosphide layer 3 is square. The P-side bonding wire electrode 1 is circular and located on the gallium phosphide layer 3; there is an indium-gallium-phosphide layer between the P-side bonding wire electrode 1 and the gallium phosphide layer 3, wherein the content of indium is 50%, and the content of gallium is 27%. , the balance is phosphorus; the indium gallium phosphide layer can improve luminous efficiency, and the special composition design can further promote t...

Embodiment 2

[0051] Such as figure 1 As shown, a LED chip with a new structure, the LED chip includes an N-side electrode, a substrate, an active layer, a gallium phosphide layer 3, a P-side bonding wire electrode 1, an extended electrode 2, a current blocking groove 4 and an etching hole , the current blocking groove is located on the diagonal line of the chip P face, and its manufacturing steps are:

[0052] (a) Prepare a preliminary electrode whose structure is N-face electrode, substrate and active layer (the material of the active layer is aluminum gallium indium phosphide with a thickness of 7 μm) from top to bottom, and then grow indium on the surface of the active layer Gallium phosphide layer, using metal organic vapor phase epitaxy (MOCVD) to grow an indium gallium phosphide layer on the P side of the LED chip. The gas phase reactants of MOCVD are trimethylindium, trimethylgallium and phosphine, and the mass ratio is 1:1 :100, under the condition of 700℃ and pressure 50Torr, the...

Embodiment 3

[0064] With embodiment 1, difference is that in the manufacturing step of the LED chip of a kind of novel structure, the thickness of active layer in step (a) is 9 μ m, the thickness of gallium phosphide layer 3 is 9 μ m; The viscosity of the positive photoresist is 30PaS, and the homogenization speed is 3000 rpm; the gold etching solution in step (f) is a mixed solution of iodine and potassium iodide, which is configured by adding 3000ml ultrapure water to 250g iodine and 250g potassium iodide ; The etching gas in the step (h) is boron trichloride, ethylene, argon and helium, and its flow rate is respectively: boron trichloride: ethylene: argon: the volume ratio of helium is 27:5 :45:60, the cavity pressure is maintained at 40Torr during etching, and the etching depth of the GaP layer is

[0065] The red-yellow LED chip produced by the above method has a chip size of 9mil, and the light efficiency of the LED chip reaches 28-30lm / w under the current of 20mA, which is 0.4 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com