Production process of wedge-shaped cushion block of oil immersed power transformer

A power transformer and production process technology, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problems of unable to wind the wire, the winding transposition transition is not smooth, the filler structure is loose, etc., to achieve insulation performance And mechanical strength is good, the mass production of machine tools is improved, and the outer surface is smooth and flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention is further described below in conjunction with the drawings and embodiments:

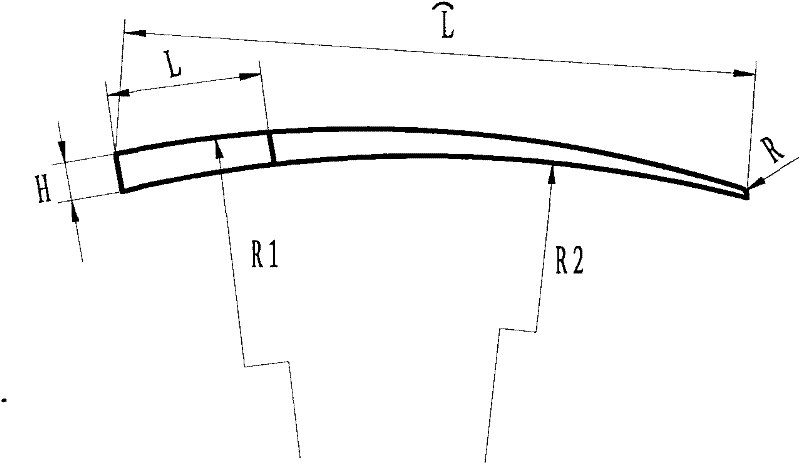

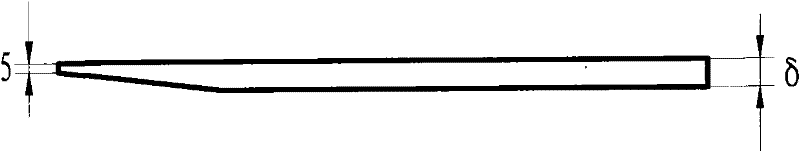

[0044] With continuous winding (such as figure 1 Shown) and the outer wedge-shaped spacer used in the open position of the winding coil (such as figure 2 with image 3 Shown) as an example, the specific process steps are as follows:

[0045] (1) Determine the relevant size of the wedge block according to the transformer winding:

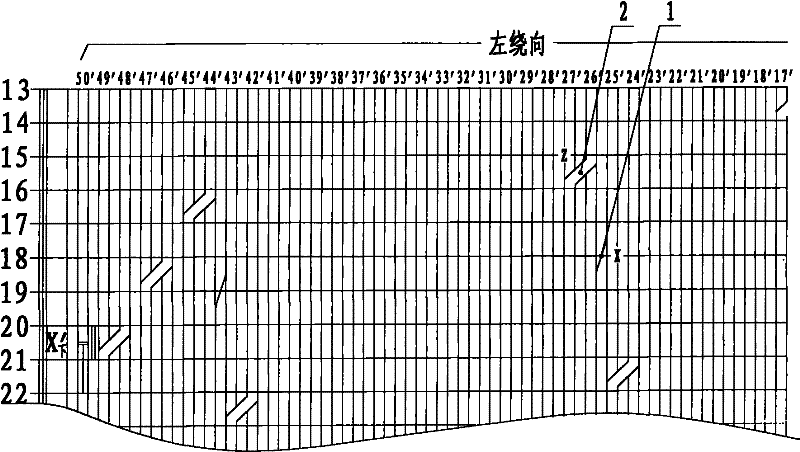

[0046] figure 1 One place is external transposition, two places are internal transposition. The horizontal line represents the brace, and the vertical line represents the transposition wire of the wire winding. The outer diameter of the continuous winding is 1827mm, and the adjacent open position transposition The number of gears between the center and the bottom transposition center is 2.5, the total number of gears is 32, the ratio of the winding circumference to the total number of gears is 179mm, the width of the dovetail pad is 50mm, and the winding wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap