Axial plunger pump for increasing flow and sealing pressure

A technology of axial piston pump and sealing pressure, which is applied in pumps, multi-cylinder pumps, liquid variable displacement machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

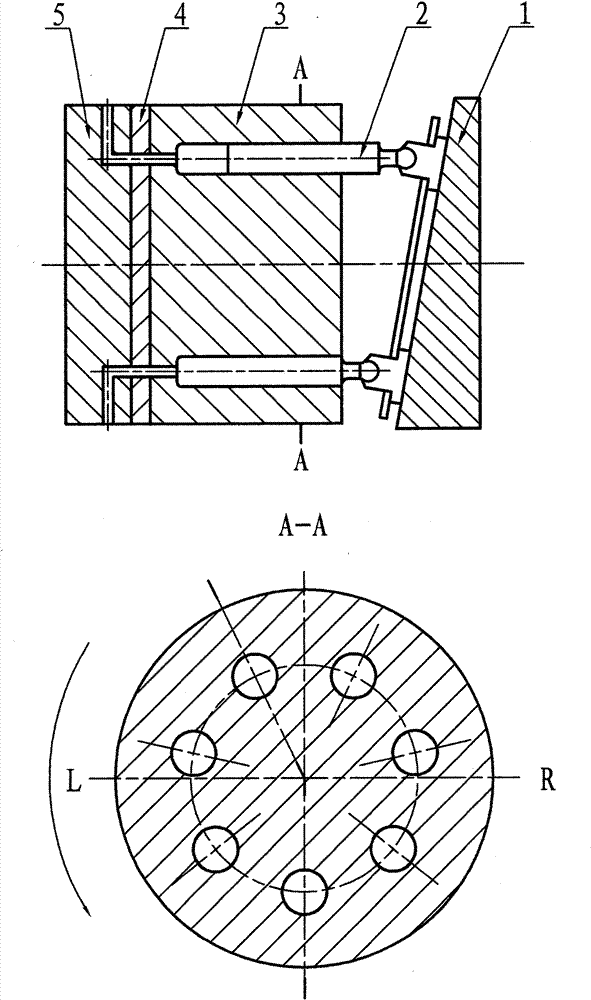

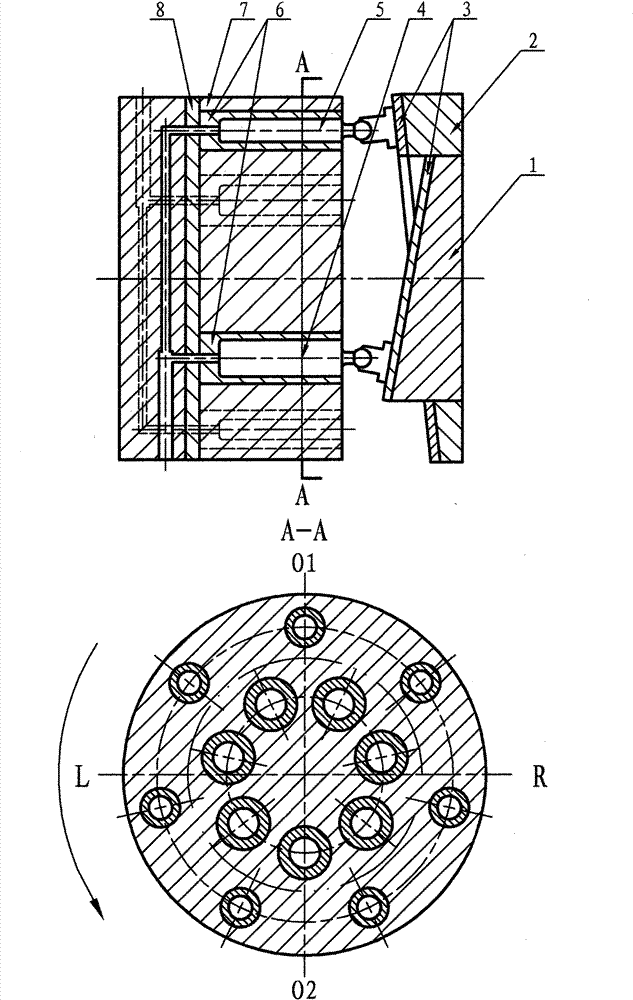

[0021] First of all, in the specific implementation of the manufacture of one pump and two sets of booster systems, three problems must be solved:

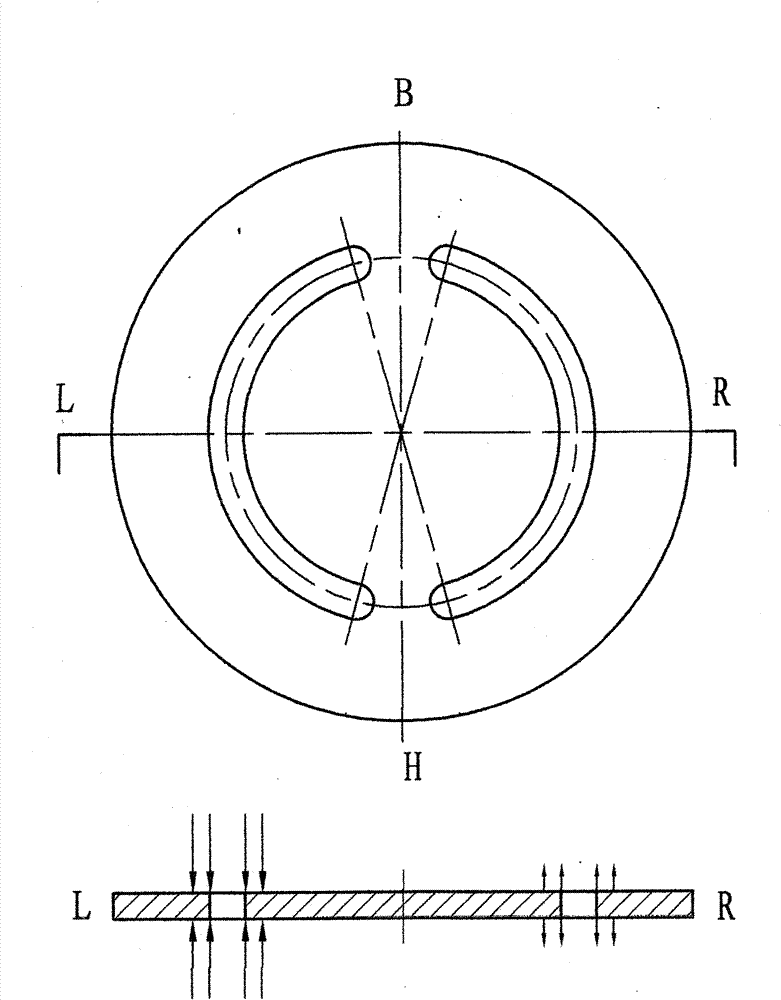

[0022] 1. In order to achieve 180° staggering of the highest points of the inner swash plate and the outer swash plate (on the long axis of the ellipse boundary of the inclined plane), the workpiece must be pre-marked as a reference line for the highest point and the lowest point of the inclined plane. This reference line passes through The center of the two ends of the workpiece is connected to the busbar of the workpiece cylinder, and the busbar connecting the highest point and the lowest point of the inclined surface is drawn on the workpiece cylinder, and the reference line of the busbar is always kept during processing on the coordinate machine tool. When assembling, the inner bevel Aligning the reference lines of the busbars of the inner swash plate and the outer swash plate can ensure that the highest points of the inner swash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com