Balance shaft module

A technology for balancing shafts and crankcases, which is used in engine lubrication, mechanical equipment, pressure lubrication of lubrication pumps, etc., can solve problems such as obstacles, and achieve the effect of simplified maintenance and compact overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

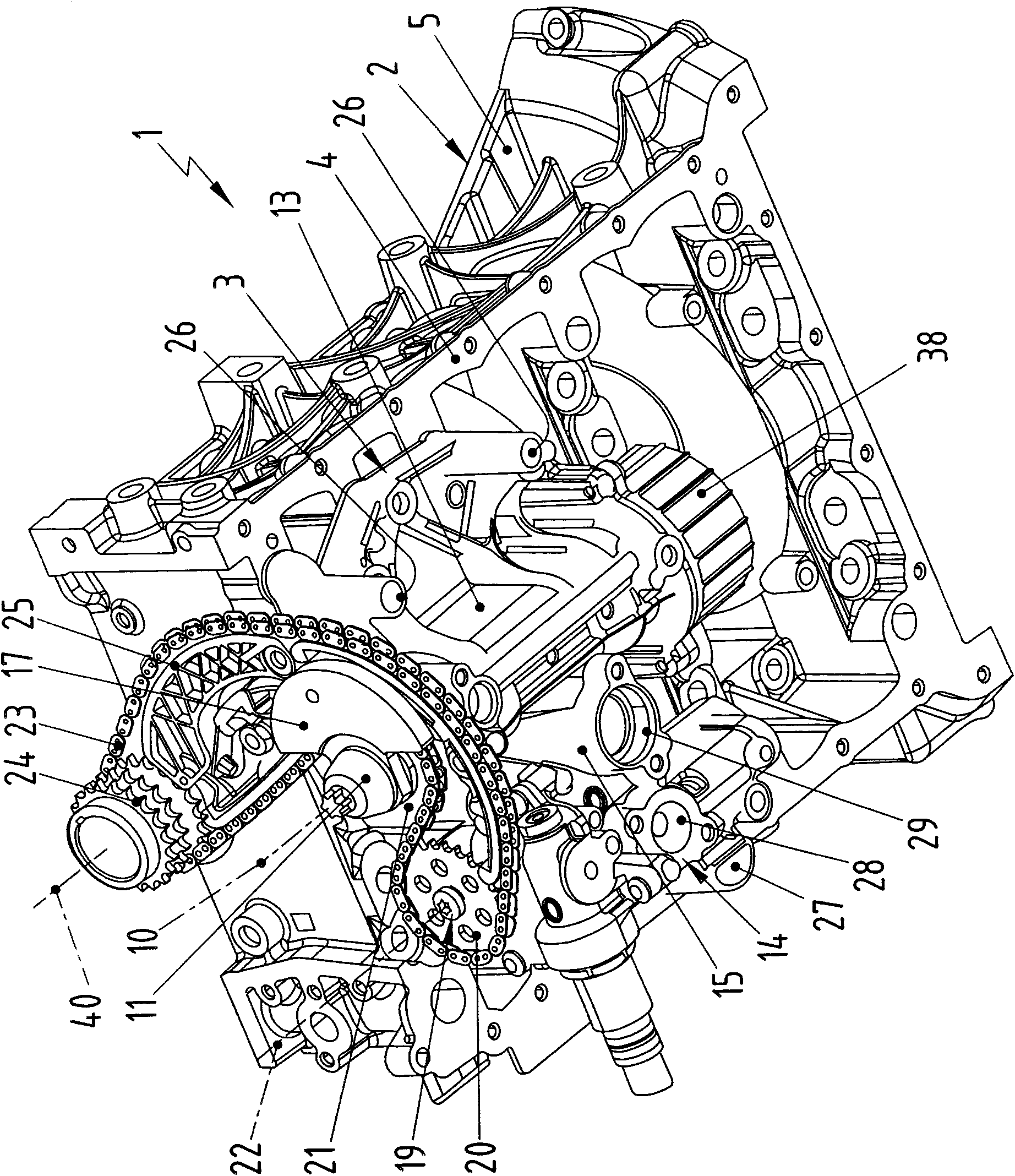

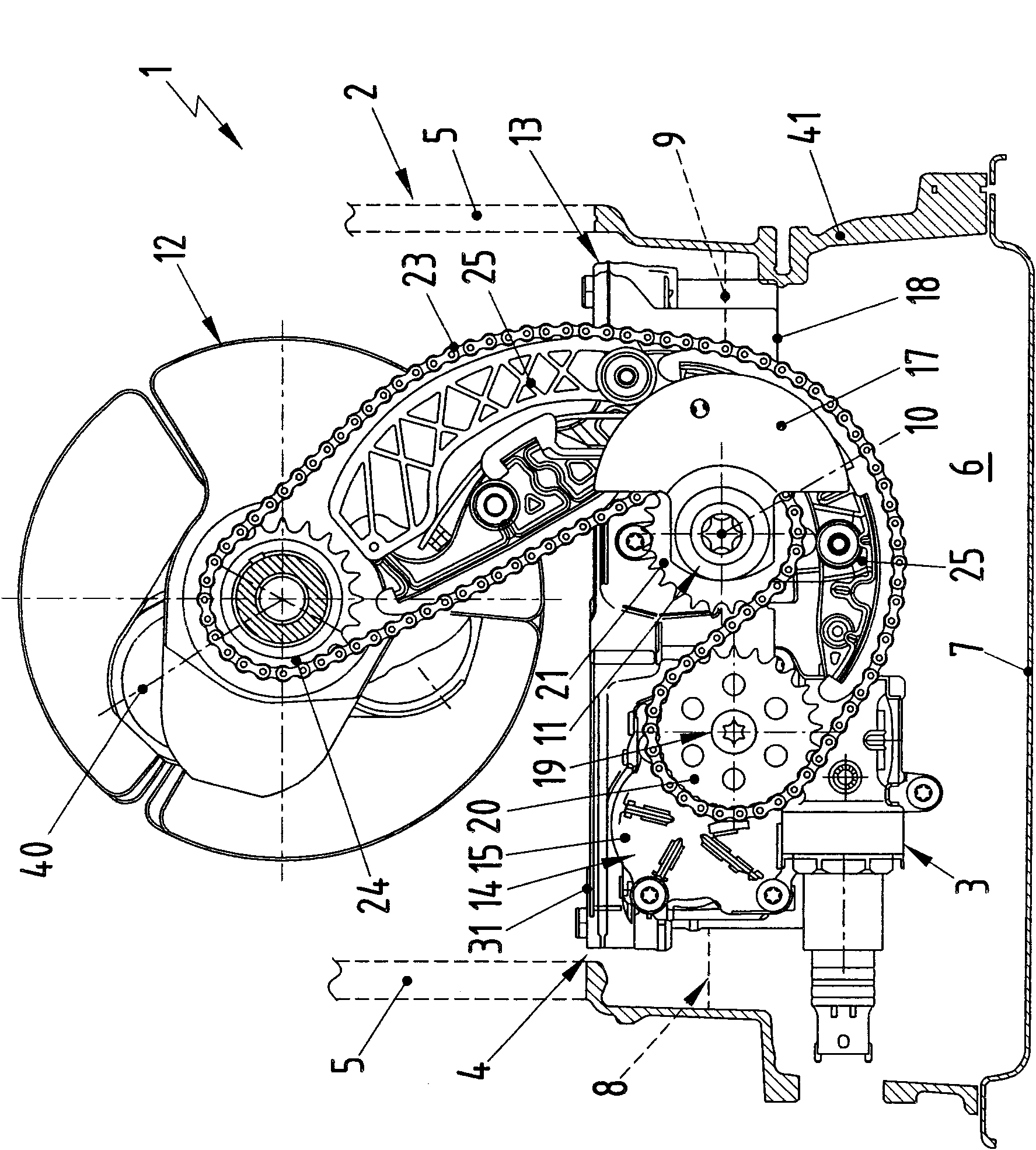

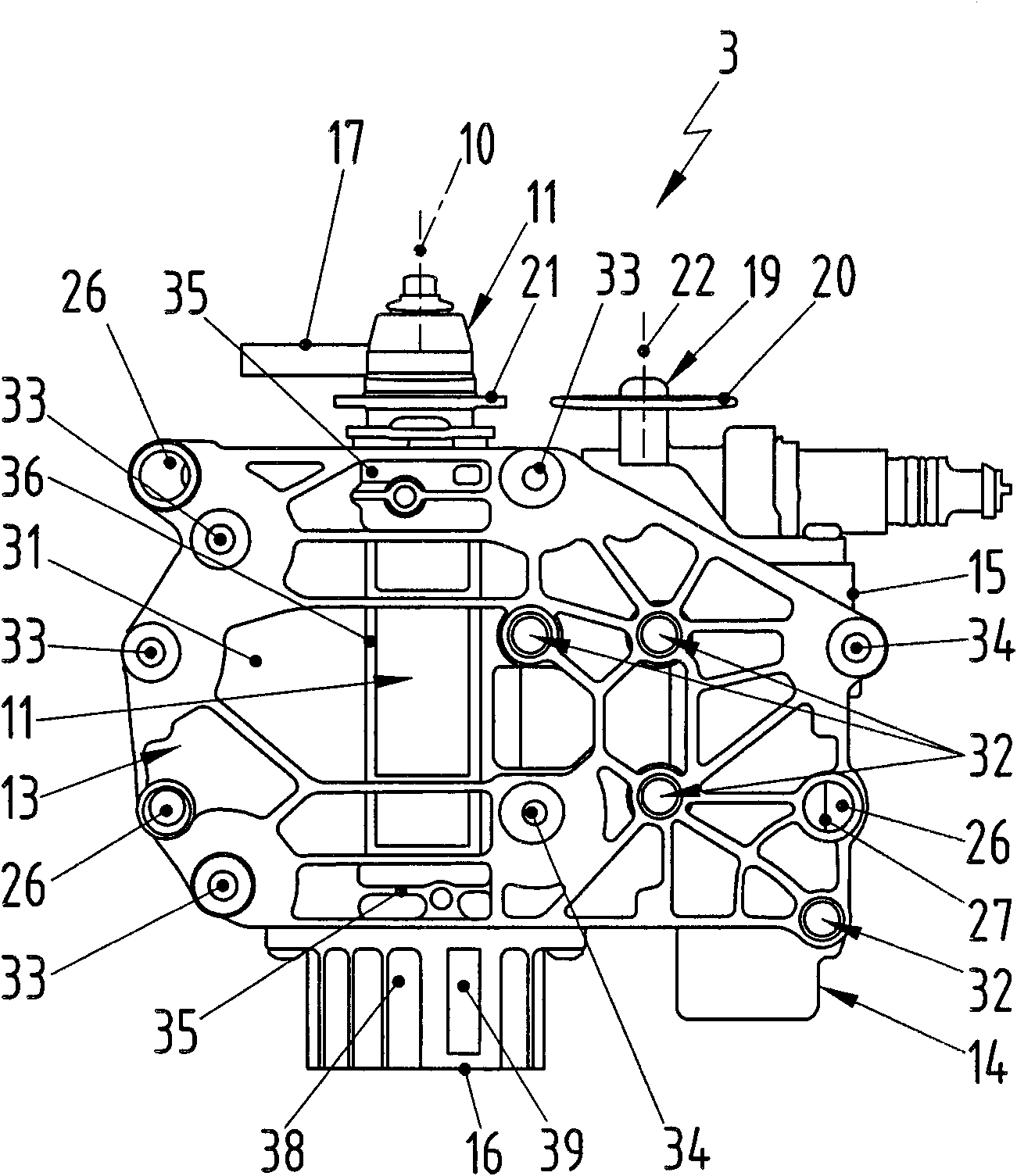

[0030] corresponds to figure 1 with figure 2 , a piston engine 1 , shown only in part, comprises a crankcase 2 and a balance shaft module 3 , which is mounted on or in the underside 4 of the crankcase 2 . In this context, the expressions "bottom" and "top" relate to the conventional installation situation of the piston engine 1 when it is used, for example, in a motor vehicle.

[0031] In crankcase 2, figure 1 with figure 2 Only one lower part 5 is shown, whose lower side 4 simultaneously forms the lower side 4 of the crankcase 2 . An oil guide housing 41 is mounted on the bottom of the crankcase 2 or on the bottom of the lower part 5 , which surrounds a cavity 6 laterally. In this way, the crankcase 2 has the cavity 6 together with the oil guide housing 41 on its underside 4 . The cavity 6 is open in the downward direction and closed in the downward direction by an oil pan 7 which is attached from below to the oil guide housing 41 of the crankcase 2 . The function of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com