Ball valve with filter screen

A tennis ball and belt filter technology, which is applied in valve details, valve devices, filter separation, etc., can solve the problem of bulky and labor-intensive removal of impurities and foreign objects in the pipe network by filters, large social impact and economic losses of heating systems, disassembly and filtration Network labor intensity and other problems, to achieve the effect of increased cleaning times, labor cost savings, and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

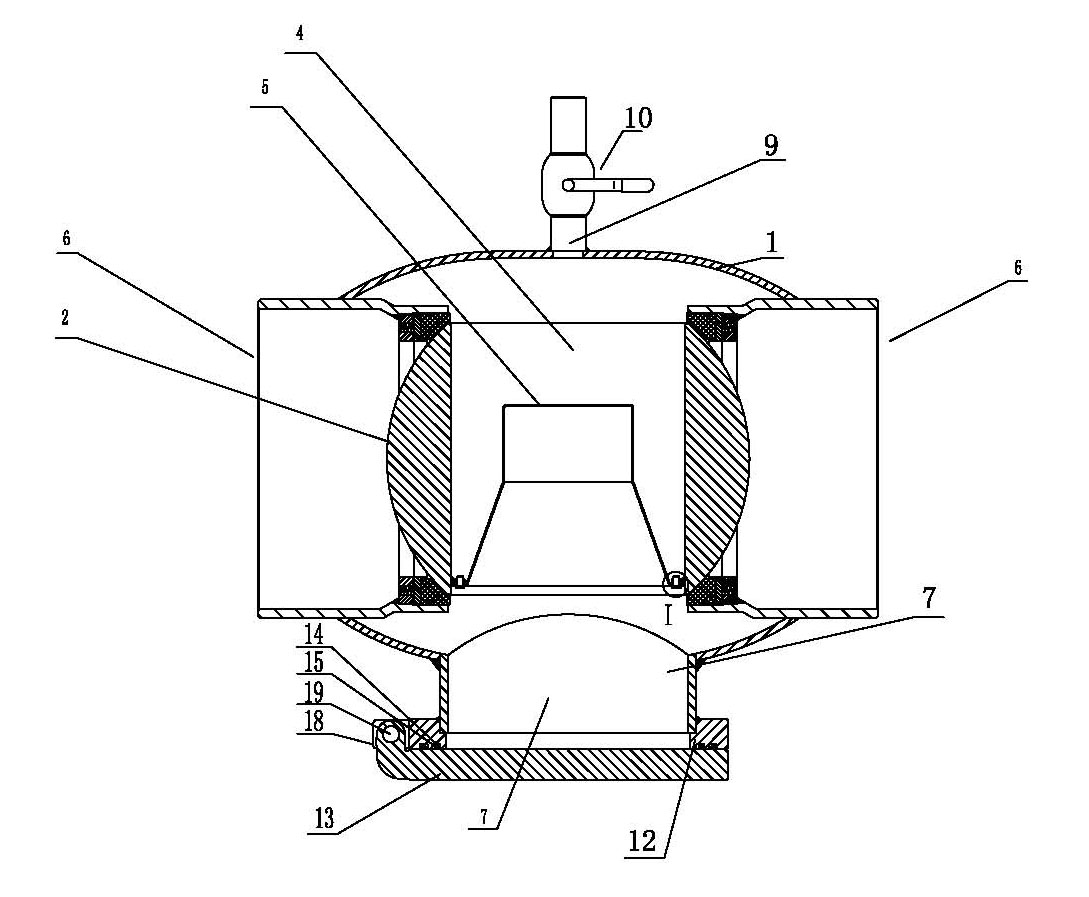

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

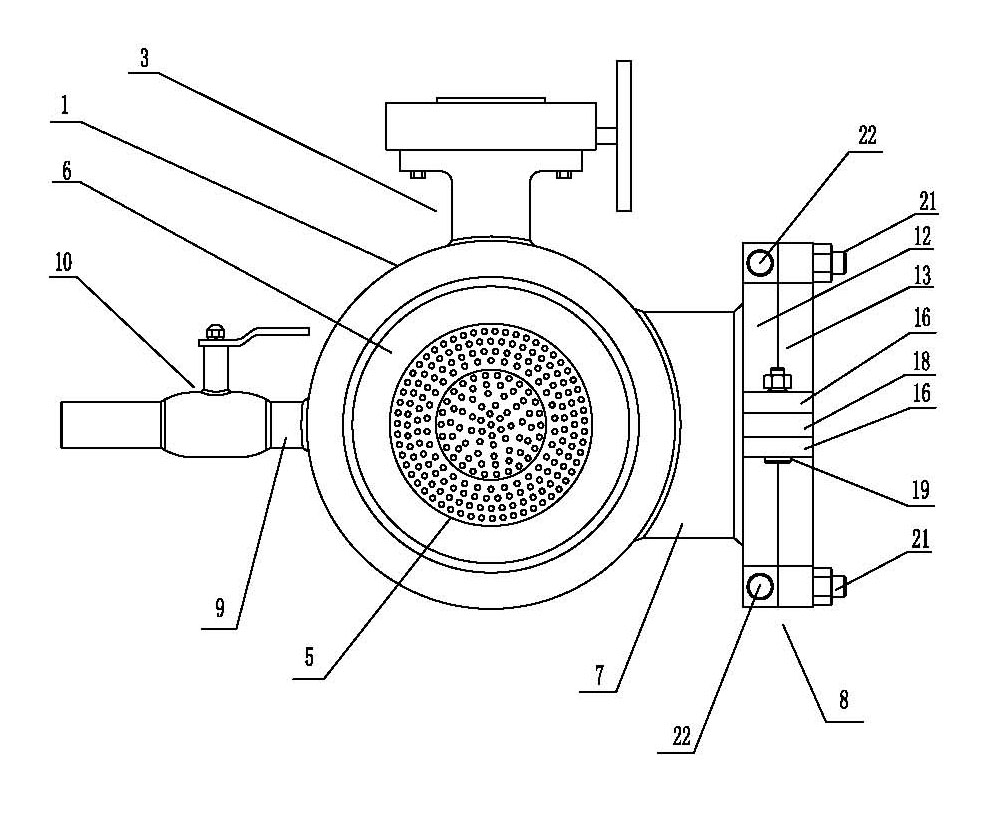

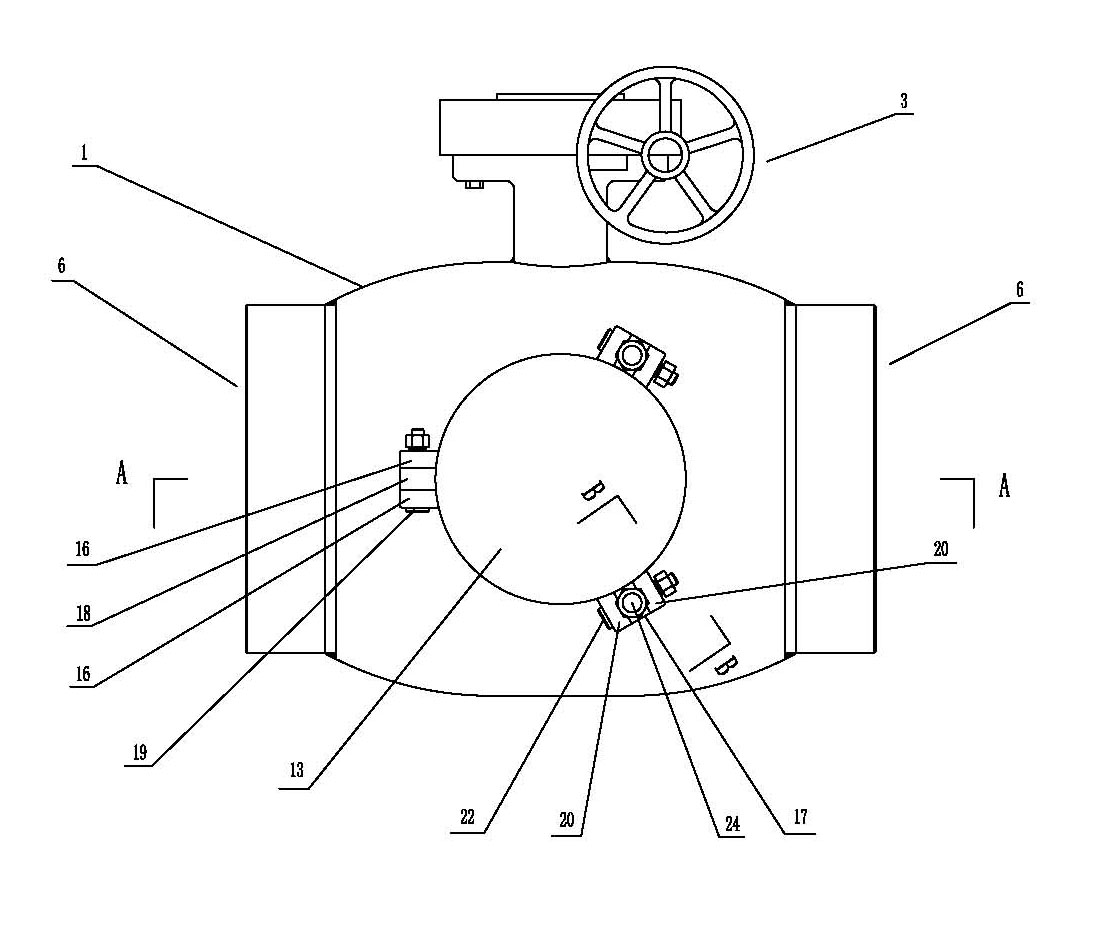

[0030] Such as figure 1 , figure 2 , image 3 As shown, the ball valve with filter of the present invention includes a valve body 1, a valve ball 2, and a valve actuator 3, and the valve body 1 is provided with a valve ball 2 inside.

[0031] The upper end of the valve body 1 is provided with the valve actuator 3 connected to the valve ball 2. The valve actuator 3 is a mechanism that can drive the valve to fully open or fully close. The existing technology is adopted, such as electric 90° single-rotary actuator. Institutions, fluid-driven or linear output actuators, fluid-driven partial single-turn actuators.

[0032] Such as image 3 As shown, the center of the valve ball 2 has a through hole 4, and one end of the through hole 4 is provided with a filter screen 5. The shape of the filter screen 5 is preferably horn-shaped or the horn-shaped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com